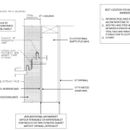

Wall section – help with air and vapour barrier

I am using a commercial insulated metal panel system to insulate on the exterior of the sheathing. Panels are arranged horizontally (40″ high and up to 40′ long but I’ll likely cut to 10′ as they would be too heavy) and secure through plywood to 2×6 studs using metal self-tapping screws.

Appreciate the community’s help in determining best location for air and vapour barriers / retarders in this assembly.

1. INTERIOR STEEL FACE AND CAULKING? ALLOW MOISTURE TO DRY TO INSIDE?

2. ADD PEEL AND STICK AIR BARRIER BETWEEN PLYWOOD AND INTERIOR STEEL FACE AND REMOVE CAULKING SO IT MIGHT DRY TO OUTSIDE AND INSIDE?

3. OTHER?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I'm new to the building industry, so perhaps someone else should chime in, but I'll give it a shot.

You didn't state climate zone, but I'll assume it's cold. I thought metal SIPS were air tight and vapor impermeable... aren't they used as standalone roofing / walls over steel frames commercially? Assuming vapor impermeability (the seams aren't going to make enough of an impact caulking or no), you'd have to allow the wood assembly to dry to the interior, so don't use poly on the interior side.

If you're worried about having a separate air barrier, you could always tape the plywood seams and treat it like a zip system wall or add poly under the metal SIP.

Sorry, I forgot to say I'm in ASHRAE Zone 5 (Toronto).

These insulated metal panels (IMP) aren't structural in that they aren't meant to provide racking strength or bear load.

Thank you for your thoughts on the vapour impermeability and I agree, but the manufacturer mentioned evaporation of any moisture that made it into the joints, or behind the steel panels if I didn't caulk.

If that isn't really likely, then I would likely follow original manufacturer's design intent and caulk, making this the air barrier. What I am unsure of is the details and whether I can easily connect other air barrier elements to these metal panels (tapes most likely) at openings and where the panels butt against one another horizontally and at corners.

Should I add a secondary air barrier using peel & stick on the plywood? I think this would have to be vapour permeable and not poly because any moisture that got between the IMPs and the plywood is what I am worried about. This layer would also have the additional benefit of weatherproofing my assembly before I can get all the IMPs installed? The peel & stick is expensive though, so I'm unsure.

Perhaps I only tape the seams with vapour permeable peel & stick, and get the IMPs on as soon as I can. If moisture gets past the IMPs, I can rely on permeability of plywood that becomes more permeable with higher relative humidity (The second page of my attachment shows a graph depicting this), allowing assembly to at least dry out to inside.

Jerry,

I think that it's unlikely that there will be much water that gets past the SIP seams. But if you are worried about that possibility, the usual solution would be a layer of crinkly housewrap to allow a small amount of drainage -- in this case between the SIPs and the plywood sheathing.

This house is being built according to PERSIST principles, so it makes sense to establish the air barrier and vapor barrier at the sheathing level. To create an air barrier, tape the plywood seams with Siga Wigluv tape, followed by housewrap as a WRB. Or you can install the peel-and-stick on the plywood if you want.

For more information on PERSIST, see Getting Insulation Out of Your Walls and Ceilings.

Yes, PERSIST is what I was following with modifications.

Did you really mean to say the rainscreen gap is between the insulation and the sheathing? Doesn't that just bypass the insulation...essentially a huge air leak.

I was hoping to avoid Peel & Stick on all surfaces since its so expensive. Is the Siga tape that much better than something like a Henry Blueskin VP100 or VP160 (vapour permeable and it comes in 4" wide rolls)

How important is the WRB if I can get my metal panels up sooner rather than later?

Jerry,

I must not have had enough coffee when I posted my last comment. You're right, of course. I have edited the comment to reflect what I should have written. Crinkly housewrap is the usual solution to your worries.

Q. "How important is the WRB?"

A. Every wall needs a WRB; it is required by code and a good idea as well. Even PERSIST homes need a WRB. For more information, see All About Water-Resistive Barriers.

Thanks again. The metal panels (IMP) actually have a low 'corrugated' profile to make them stiffer so they don't oilcan, so there are drainage channels if you orient them vertically. Unfortunately, I am orienting them horizontally for various reasons.

So I read the WRB article again (I had read this, but forgotten). I'm not sure how the wrinkly WRB will create a mini-drainage gapWith the IMPs screwed into the studs, won't everything be compressed flat? And isn't that what we want to prevent air from going 'around' the insulation?

Or are we hoping for tiny vertical gaps separating the interior metal skin from the WRB / sheathing since the IMPs can't be perfectly flat?

i was also unsure about the statement about higher perms is overkill because doesn't plywood sheathing permeability greatly increase with higher R.H. (in my attachment) so wouldn't we want to ensure the WRB is not the 'bottleneck' to drying to the interior?

There is no mention of peel & stick air/vapour barriers as WRBs. Are they overkill? I'm searching the site for articles on Henry's Blueskin VP100 or VP160 (vapour permeable).

Jerry,

For your assembly, it doesn't really matter if you choose a vapor-permeable housewrap or a vapor-impermeable housewrap. As long as your plywood sheathing can dry to the interior -- and clearly, it can -- who cares what the permeance of your housewrap is? In winter, a vapor barrier in this location makes sense.

Joe Lstiburek has an article that explains how crinkly housewrap can help redistribute moisture and provide some drainage. (By the way, testing shows that attaching siding to this type of housewrap won't crush the wrinkles.) Here is a link to Lstiburek's article: Mind the Gap, Eh!

I thought it was a no-no to have 2 vapour barriers. In this case interior metal face + caulking and housewrap. Any water that got into the assembly outboard of the plywood should be allowed to dry to the interior since it would have a hard time going outward, no?

I've read the Mind the Gap article before, but should probably review again. I just wasn't sure about metal clamping onto it.

Jerry,

I really don't think that you'll get much water between the seams of your SIPs, but if you are worried about that eventuality, you're right -- you should choose vapor-permeable housewrap. Since most types of housewrap are vapor-permeable, including most types of crinkly houswrap, that shouldn't be difficult.