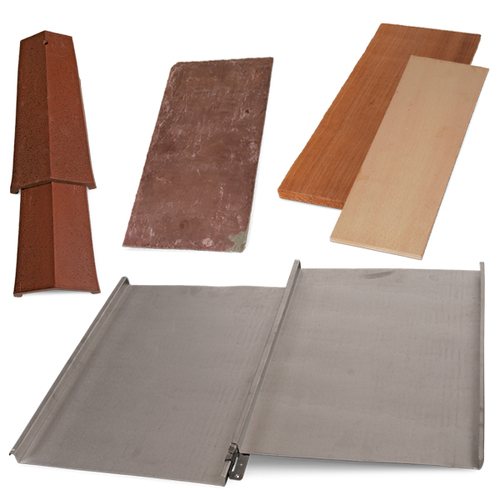

ABOUT WOOD SIDING

A natural and traditional choice

Nothing has a longer history as a building material in the United States than wood. It has many advantages when used as siding, but its few drawbacks have pushed many builders and homeowners toward other materials, some of which are manufactured to look like wood.

On the plus side, wood is easy to cut and shape, doesn’t require exotic tooling, doesn’t emit noxious dust or fumes, and is adaptable to many house styles. Wood is a natural product that requires minimal manufacturing before use.

Time to get out the ladder and paintbrush

Wood also has three major drawbacks. The first is maintenance. Some grades and cuts of wood are much more durable than others, but, all wood siding, with the possible exception of cedar shingles, lasts longer when it’s regularly treated with preservative or paint.

A second issue is resource use: The best grades of wood siding may come from clear-cuts of old-growth forests. Specifying siding that has been certified by the Forest Stewardship Council (FSC) is a way around the problem, but it isn’t always easy to find and may be more expensive.

The third downside is the price: The best grades of wood are very expensive.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

0 Comments

Log in or become a member to post a comment.

Sign up Log in