Conditioned air moving through light switches and other wall penetrations can find its way into the attic, too. Seal where the drywall meets the top plates to solve this problem.

Get your finger ready—and some caulk, spray foam, or acoustical sealant

Video Transcript:

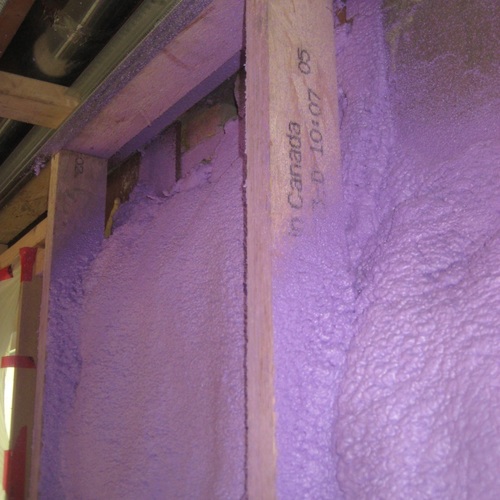

Where the wall plates of interior partition walls come up to the bottom of the ceiling joist, we’ve got gaps between the drywall and the plates themselves, and those plates are going to run either perpendicular or parallel to the ceiling joists. Where we have it perpendicular, the wall plate you can see in the drywall. And over here, where we have it parallel, they put in 2×6 blocking that supports the ceiling drywall but sits on top of that top plate.

There are slightly different approaches to sealing both of those situations. Between the drywall and the top plate of the wall, we’ve got a few different choices of materials we can use to seal up. Probably the simplest and easiest is just a really good, high-quality caulking. You want something that’s elastomeric, which means that it’s stretchy after it seals up. I tend to go for something that’s a little less expensive but works just as well, which is an acoustical sealant. It usually comes in larger tubes, and you find it at commercial suppliers. The stuff is very sticky, and it doesn’t completely cure—and that’s important. It’ll skin over, but it’ll stay sticky, stay adhesive, and be able to move with the materials as moisture, temperature, and so on change the dynamics of the material.

Now, another choice would be a high-expansion or low-expansion spray foam. One of the challenges with this stuff is that it’s only good when…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

3 Comments

good stuff. We need more of

good stuff. We need more of this. I've seen the problems associated w/ the spray foam in the field - I can show you pictures. Curious to know what expereience people have had w/ the owens corning energy complete system and the knauf eco seal system. What's really needed is something like the eco seal system but that's available as a sealant and not part of an insulation package.

Hi Mike,

This how-to video is really helpful. Thanks! Can you say anything about Dupont's GreatStuff gasket polyurethane foam sealant product, here: https://www.greatstuff.dupont.com/products/pro-gasket-polyurethane-foam-sealant-pro-dispenser-gun.html? I've been using it everywhere in the attic I've found a gap or joint - wood members, joists, and/or drywall. After a year since first using, I think the product has retains its elasticity, but I wonder if it's strong enough over time as framing members shift or move. Maybe I should go back over the wall plate gaps with an acoustic sealant as you suggest.

I can speak to that gasket product, because I had a small part in testing it. (I live in the home town of "Dowpont" Building Solutions)

It's not polyurethane, it's some kind of latex/water based product. It's probably more like acoustic sealant than it is like regular great stuff. Once it sets it's incredibly flexible and stronger than I expected. It was specifically designed to stay flexible and stick to wood and drywall. I'd say it's far more likely to put up with movement than it's polyurethane cousin. I really like it for what you're doing, sealing in attics and such. The water clean up is nice, and the off gassing seems less severe to be around.

The down sides are that it's struggles below freezing, and that it won't setup properly in a really humid environment. We'd tried applying it as a drywall gasket (the primary intended use) right after a damp spray cellulose install and it was a disaster. The damp wood and high humidity cause it to run and not puff up properly.

I've also used it to make a puffy gasket for an attic hatch (you have to be very neat and tidy applying it) and it work really well. It conformed to imperfections while needing very little weight to compress it. I had some stuck to various materials that it kept checking on for a little while and it never seemed to lose elasticity. Also, it's just white instead of some high-viz color, you can just fill the odd hole with it and it doesn't stand out like a sore thumb.

Hopefully this helps.

Log in or become a member to post a comment.

Sign up Log in