A Wisconsin-based company has developed a way to replace cast-in-place concrete foundation walls with insulated composite panels that can be set in place in just a few hours.

Epitome foundation walls were developed by a builder who was tired of scheduling delays caused by a shortage of concrete subcontractors, according to the manufacturer. Glenn Schiffmann began looking at alternatives, including precast concrete. But in the end, he settled on a composite with a core of rigid foam insulation. What started as an answer to his own construction problems has blossomed into a company called Composite Panel Systems that now ships foundation components all over the country.

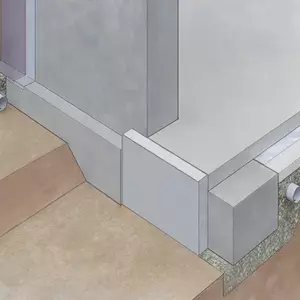

Justin Mills, the company’s executive director of operations, said builders who use Epitome foundations won’t have to wait for foundation subcontractors to set up and take down concrete forms, or schedule a ready-mix truck. Once the panels are on site, they are set on concrete footings in as little as 2 1/2 hours.

“It’s a one-step process,” he said. “When it’s in, it’s done.”

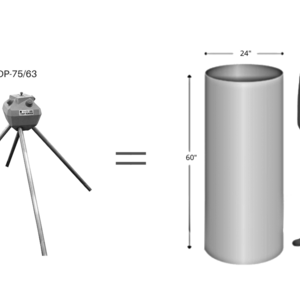

To date, the company has installed nearly 500 foundations in 36 states, Mills said. The 24-foot by 9-foot panels are fabricated by FiberTech Industries in Washington Courthouse, Ohio, and shipped by truck to local fabricators who are equipped to cut panels to size, add door and window openings, and erect them on the job site.

NTA, a third-party evaluator affiliated with the International Code Council, has found the panels compliant with 2012 and 2015 versions of the International Residential Code and the International Building Code.

The fire- and water-resistant panels have an R-value of 16.5 and are manufactured with integral composite studs to the inside for attaching drywall or other finish materials. Mills said the manufacturing process is similar to how composite boat hulls are formed with a mix of fiberglass,…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

13 Comments

What are these made of exactly? If this was in the article, sorry, I missed it. I just see repeated use of the word "composite".

Do you mean plastic? That's what I think of when I read "composite" in most contexts, but lots of other materials are technically composites. For example, concrete is a composite.

In the video they're putting wood on top, which is surprising, but I can't tell what the bulk of the assembly is made of, the non-foam part.

If it's plastic, I'd be concerned about them melting in a fire, and potentially degrading when exposed to high, but sub-fire, temperatures. Unless it's a high performance plastic like PEEK or Torlon, but those are expensive and would cost a fortune in this application, so I'm curious what these are made of.

I missed that on the first read, but went back and found "Mills said the manufacturing process is similar to how composite boat hulls are formed with a mix of fiberglass, resins, and heat."

Yeah, I saw that but it seems to be describing how boats are made, and that these walls are made with a similar *process*. It's not clear to me whether they're also saying that these composite walls are made of fiberglass. If they're fiberglass, they should just call them fiberglass walls.

This reminds me that I think certain grades of fiberglass would be a *great* material for roof sheathing/decking, and wall sheathing, replacing plywood and OSB. I'd love to have a huge, seamless, monolithic fiberglass roof decking, similar to the sorts of things Holland Composites makes (https://www.hollandcomposites.nl/en/). Same with wall sheathing -- it would be awesome to have giant monolithic wall sheathings, one piece for each wall.

Even better would be a fiberglass roof deck that was specifically designed for a certain type of solar panel or solar shingles, and solar panels/shingles designed to integrate with such a fiberglass roof.

Seamless fiberglass monoliths would eliminate a lot of seams and joins, make air sealing easier. They'd also be incredibly tough, shrugging at hurricanes and hail. They'd never rot or warp, or fall prey to pests.

The pièce de résistance would be to unify the two elements -- roof and walls seamlessly integrated in one giant "mushroom" of sheathing.

This would all be ridiculously expensive right now, but one can dream, and perhaps industrial 3D printing will dramatically reduce the cost by 2025 or 2030.

It looks like you're right about it being fiberglass. I poked around on their website and finally found it in their FAQ page:

"WHAT IS IT MADE OF?"

"The Foundation Composite Walls are an innovative, structurally superior, highly-insulated panel encapsulated in high-performance fiberglass reinforcements, inclusive of molded integral studs which act as pilasters."

That's a lengthy way of saying it's fiberglass. Most of their FAQ answers are like this -- ponderous marketing-speak. I don't like this company given how indirect so many of their answers are. Such as:

"HOW LONG WILL THE PRODUCT LAST?"

"Comparable composite products such as draw bridges and underground storage tanks have been shown to outlast their concrete equivalent."

By the way, was this article an advertisement? I mean did the company pay GBA for it? Anyone know? It's hard to tell these days. It's strange how the article obsessively uses the word "composite" to talk about fiberglass. That's what I would expect in marketing copy -- I think businesses would think that composite sounds better than fiberglass, and makes the product seem more technologically advanced.

Hi BlueSolar.

This article was not an advertisement. And I agree, it can be hard to tell these days with all of the different ways advertisers and media companies work together.

There is sometimes an honest line between purely editorial content, sponsored content, paid content, etc. Other times, there isn't such a clear line. This is happening across all media types--print, digital, social--and all interest areas.

At this point, GBA has none of these relationships with advertisers in place, and no paid content on the site. Everything you see here, we have complete editorial control over. I can't say that this will never change, but if it does, and I am still working here, I promise to be as transparent as possible to let you all know exactly what the content is and isn't.

“[Deleted]”

I'd love to see a comparison between this system and concrete with respect to global warming issues. Given that cement manufacturing generates a great deal of CO2, maybe composite/ fiberglass foundations is a step in the right direction.

The article compared replacing a defective concrete foundation and states the cost is lower. But how about new construction?

They do say in the article that they're 10%-15% more expensive than concrete foundations, but that they're OK with that because they're better. Maybe so, but that's going to price them out of the spec housing market. A fast install will help with scheduling, but so does precast concrete, and precast also claims to be waterproof. Neither one is waterproof at the joints, and that's where they always fail.

I was also not thrilled with the company the first time I ran across their product. Far too much marketingspeak and far too little data. Once they've got a few thousand foundations in service and we see how they perform I might get more excited.

I'm not sure about the carbon equivalent, but environmentally, fiberglass manufacturing is not great. The resins are strong sensitizers and pretty nasty for the environment. At least in a factory, they can use proper controls for exposure and waste (I hope.) The resin part is also very UV sensitive. It's going to need a lifetime sunscreen. The fiberglass strands are a high-energy product, but there's going to be a lot less of that by weight than cement in a concrete foundation. And, fiberglass can be made from recycled materials, so that's a plus.

I suppose that if the net price is right, this could be a reasonable alternative to concrete.

Concrete would also need insulation, likely foam, so you would need to add that to the carbon equation.

Carson,

I agree, but we have to be careful. Fiberglass/resin composite is a relatively good conductor. Not as good as most metals, but better than insulation. Probably about the same conductivity as brick. These panels have integral foam insulation between the fiberglass skins and that provides most of the insulating value. They've also got fiberglass 'studs" on the inside, and these might go all the way through, creating thermal shorts.

Superior Walls is sort of famous for advertising the center-wall R-value which isn't bad because of the foam insulation they put in the cavities. But the ribs create serious thermal shorts that drop the whole-wall insulation value by about 80%. More recently, they've been putting an inch or so of foam over their ribs to help with this and their whole-wall R-value is better.

So to compare apples-to-apples, we should look at the carbon cost, the $$ cost, and make sure that whole-wall R-values are consistent across different approaches. Sounds like a good project for a grad student.

They're getting too big for how small they are. Took several weeks to return a phone call and answer questions; that said, it's a great concept and I wish them success.

If anyone has any questions, I was the first to install one of these foundations in our new Construction home in Northeast, CT. We’re going on year 3 now. I’ve got nothing bad to say, but I was dealing with them direct from Wisconsin not a local distributor/fabricator. This foundation system combined with PU SIP walls has made our house incredibly efficient. We are very happy with our decision thus far. Foundation was set in less than 4 hours one morning, ready to frame the floor. One (Big) negative in new construction is that the floor system must be framed as well as basement poured before backfill. That was a bigger pain than I anticipated...

We are planning to use a fairly similar system - SIC-System - concrete free including the basement floor.

Only concrete needed is for the footings. Basement walls will get waterproofing membrane and dimple/drainage mat.

The whole house will be build with this system except for the roof. Looking at R-50 for slab and walls.

Aiming for airtightness below 0.6ACH.

Will be close to passive house in a cold climate.

https://sic-sys.com/

Log in or become a member to post a comment.

Sign up Log in