Image Credit: All photos: Jim Baerg

Image Credit: All photos: Jim Baerg The 18-inch-thick basement walls are made of stone and mortar. The home's kneewalls were sheathed with cardboard. The insulation on the attic floor is Silva-Wool, an older type of cellulose insulation. These cardboard ventilation chutes were installed to ensure that the rafter bays were properly ventilated. Foil-faced polyiso (2 inches thick) was attached to attic side of the kneewalls. A new Panasonic exhaust fan was installed in each bathroom. Before the air leaks in the electrical boxes could be sealed, the old insulation and dust had to be cleared away. Air leaks in ceiling-mounted electrical boxes were sealed from the attic with canned spray foam. We installed a deep layer (about 16 inches) of cellulose in the attic. After ventilation baffles were installed, the uninsulated sloped ceilings were filled with cellulose. This floor assembly extended over an unconditioned porch, so the joist bays needed to be insulated. The 2½-inch gap between the outer wythe of bricks and the inner wythe of bricks was insulated with blown-in fiberglass. The gap was accessed from the window jambs. Some of the windows had to be temporarily removed to access the wall cavity. After insulation was blown into the walls, the holes used to access the cavity were plugged. This plug was in the rough sill of a window opening. The basement walls were insulated with closed-cell spray foam. This reduced air leakage as well as heat flow. The new furnace has an efficiency rating (AFUE) of 95%. This table provides a list of the energy retrofit measures that were implemented over several years. This table lists the construction cost for the various retrofit measures. The pink bars show therms of gas per heating degree day (HDD). Each bar represents a heating season. This spreadsheet assumes that the cost of energy will rise 5% every year. If these energy cost predictions come true, the energy retrofit work will generate a cumulative cash flow of $31,000 over the next 20 years.

This is a story of a wonderful, tempestuous relationship. For me, it began nine years ago as an unplanned series of events: a chance encounter between a wandering idealist and small town girl. The happenstance meeting quickly progressed to an impulsive, long-term proposal. Soon thereafter, the commitment was formalized by the exchange of legal documents through the mail.

Like most marriages, this hasty decision resulted in an ongoing set of improvisations over the way we dance through life together. I was the driven agent of change; she, the stubborn, old-fashioned, and wise woman who continually forced me to prove up. These nine years have been tough but rewarding, and I’m a better man for it.

I’m talking about my house, of course. My real marriage has been rewarding in other ways. My wife Laurel has been patient, supportive, and engaged. (It really helps that she worked as a house painter and wallpaper hanger for 15 years.)

Should we buy a house?

I’m a builder and designer whose study of energy efficiency has been a life-long passion. I got my start in the mid 1970s, and have built a number of passive solar and superinsulated houses. I’ve also worked on historic houses and other projects in southwest Montana. Later, I earned a M.Arch. degree from the University of Washington and then worked for a couple of architectural firms.

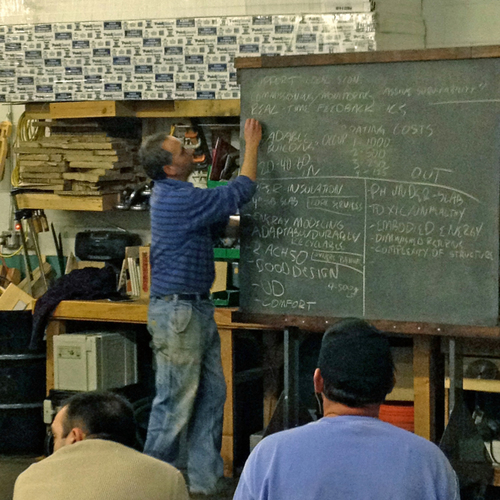

More recently, I worked as a trainer for the Montana Weatherization Training Center, where I taught classes in weatherization, insulation systems, auditing, zonal pressure diagnostics, and furnace diagnostics and repair. (I got a good education there, too.)

In 1994, Laurel and I moved from our original home in Livingston, Montana, to Seattle, where we spent 12 years going to grad school and working. After adopting twin girls from Russia, we decided to move back home to Livingston to raise them and regain some sense of normalcy, as only small town life can provide.

On a visit to my mother with the girls, we broached the subject of buying a house for the first time. A realtor friend told us that the market was very tight, but that given a year of looking, she could find us a home. At that point, my mom mentioned that a friend of hers was about to sell her house due to issues with aging. I called her up, got an invitation to visit, and immediately drove across town.

Laurel and I walked through the house with quite different reactions. She saw the shag carpeting, green-striped wallpaper, Z-brick, dropped ceilings, and heavy draperies. It was a house that hadn’t been touched in 30 years. I saw an older house with good bones: an adequate roof, a brick exterior, a newish furnace, a 3-wire breaker box, and a solid foundation. The whole process from idea to tour to decision took me about an hour.

Several months later, I received the loan documents in the mail, surprising Laurel when I asked for her signature. She swears that she knew nothing about buying a house; I’m sure that we talked about it. As I said, she’s very supportive.

Not much insulation

We rented the house out to a family for a year, then moved back home. We’ve been working on the house ever since. Out went the drapes. Out went the shag rugs and wallpaper. And out came the paint brushes. Very supportive.

Should I mention that our new house had 4 to 6 inches of Silva-Wool insulation in the attic and in some of the upstairs walls? Other than that, nada — no insulation whatsoever. The windows were a mix of single-hung vinyl replacements and leaky aluminum storm windows over old wood double-hungs. The main floor walls are double-wythe brick with a 2½-inch air gap. Being generous, that’s about an R-6.

Livingston averages 7,600 heating degree days. It’s in Climate Zone 6 and is dry, fairly cold, and very windy. The average annual wind speed is 14 mph, though the winter averages are 18 to 20 mph. Unfortunately, it is windy in the winter and calmer in the summer. The initial blower door reading from the utility audit was 2,732 cfm50. It was a cold house that first winter.

I should also mention that my wife and I are pretty old school. We keep the heat down and always lower the thermostat 10 degrees at night and when away. We religiously turn the lights off when they aren’t in use. We wash our hands and the laundry with cold water, wash clothes and dishes with full loads, and we heat the upstairs hardly at all.

HOUSE AT A GLANCE

Location: Livingston, MontanaSize: 2,200 square feetDate of Construction: 1914Bedrooms: 4 or 5Bathrooms: 2Foundation: Full basement; 18″ rubble stone walls, concrete floorFirst floor walls: 2 wythes brick with 2½” air gapSecond floor walls: Rough-sawn 2x4s with shiplap sheathingSecond floor siding: Cedar shinglesRoof framing: 2×6 rafters and ceiling joistsExisting windows: About half were original wood single-glazed double-hung windows with aluminum storms; half are replacement vinyl single-hungs with U-0.5 glass.Existing doors: Wood panel doors.Space heat: 120,000 Btu/h natural gas furnace was replaced with 80,000 Btu/h 95% condensing furnaceDomestic hot water: Gas water heater (atmospherically vented)Kitchen range: ElectricClothes dryer: Electric

Over these last eight years, I’ve systematically worked my way through the house, from the attic to the basement. My goal is to upgrade the house without affecting the historic appearance of the house. I’ve gone slowly, thinking about each step for years. I’ve also tracked my utility bills religiously. It is my most intensive case study.

Good bones

The form of the house is simple and compact, with a 12:12 roof, not unlike what we are now seeing being designed for Passivhaus buildings around the country. The unheated front porch under the upstairs bedroom and the back porch provide transition spaces to the outdoors. Unlike many houses of the era (1914), the rooms sizes are generous, with high ceilings, wide openings, and large windows. It is really delightful to live in: a good family home.

As I said, the house has good bones. There are only a couple of places where the brick arches over the windows have cracked. Otherwise, the brickwork and the 18-inch-thick rubble stone walls in the full-height basement are as solid as when they were built (see Image #2, below).

The main floor walls were brick inside and out, with plastered interiors. The second-floor framing is rough-sawn fir with shiplap sheathing. The upstairs is a classic story-and-a-half with balloon framing and two shed dormers. The exterior walls in the kneewall attics were sheathed in cardboard at some point, and most of the second-floor walls were insulated with Silva-Wool, a brand name for a precursor of cellulose insulation (see Image #3, below).

One of the benefits of an uninsulated, leaky structure is that there were no signs of moisture in the house other than some efflorescence on the basement walls and on the brick chimney in the attic. This house is as strong as when it was built. With care, it should last another hundred years. I just love the rough-sawn fir framing, the old trim, and the brick walls.

The auditors gave us a “to do” list

Soon after moving in, I started on my upgrade program. First, I applied for a utility audit.

The auditors did a blower door test, installed a few upgrades, and made a series of recommendations for additional insulation. To date, we’ve done everything on their list, and more.

Efficient lights and appliances

Some of my decisions have been easy. I’ve replaced almost all of the lights with CFLs the first year and more recently installed some LEDs.

We bought a front-loading washer and dryer set and hung up a multi-line retractable clothesline outside. As time went on, and the old appliances started to fail, the other appliances have been replaced with better Energy Star products. The dryer, which is electric, doesn’t get used much, except in the coldest time of the year. The kitchen range is a standard electric-resistance glass top.

Insulating all five attics

My first major project was to rework the attic. It is in five sections because of the story-and-a-half structure and the two shed dormers.

I wanted to connect the four kneewall attics with the upper main attic to provide ventilation, so I installed cardboard vent chutes at the outside eaves, and up the sloped sections between the lower and upper attics (see Image #4, below). The kneewalls were sheathed with cardboard and had been blown with Silva-Wool. I added 2 inches of foil-faced polyisocyanurate to the kneewalls, taping the joints and foaming the edges (see Image #5).

I also built a stout plywood attic hatch.

After installing and wiring in smoke detectors, some extra outlets, and a new bathroom exhaust fan (see Image #6), I sealed up all the wire penetrations, junction boxes, and gaps around the vent stacks (see Images #7 and #8). I didn’t systematically seal up the cracks at the top plates of partitions (because the existing insulation was in the way) and now I wonder about that decision. I also didn’t install blocking to seal up the joist cavities below the kneewalls before blowing in insulation on the flats.

After all this prep work, the insulators blew R-60 of cellulose over the existing Silva-Wool insulation (see Image #9).

After blowing insulation in the attic, the pressure difference between the house and the attic zones was measured at 46 Pascals when running the blower door.

Blower door results keep getting better

I came back with the infrared camera and blower door a couple of times after the attic was insulated. I found a couple of dozen wall cavities and sloped ceiling cavities that weren’t insulated. These cavities were then blown with dense-packed cellulose (see Images #10 and #11).

Prior to refinishing the fir floors upstairs, I also pulled up the quarter-round molding and caulked the joint between the flooring and baseboard.

An old gas fireplace upstairs was connected directly to a kneewall attic, so the fireplace had to be dismantled and the area sealed. Beyond that, I’ve installed new door thresholds and weather-stripping and sealed plumbing penetrations in the basement ceiling.

A recent blower door reading, prior to insulating the basement, was around 1,850 cfm50. After spraying the basement walls, the reading dropped to 998 cfm50. Eliminating the open combustion furnace helped too.

Four new vinyl windows

The windows in the house were a mix of original wooden double-hungs with aluminum storms and single-hung vinyl replacements, none of which were very airtight.

Our upstairs is particularly exposed to winter winds, so I replaced four of those wooden windows with new vinyl casements that had triple weatherstripping and multi-point locking hardware. The new windows had a U-factor of 0.29, the lowest U-factor I could find locally.

Blown-in fiberglass fills the gap in the brick walls

After taking a couple of years to recuperate and think, I committed to insulating the double-wythe brick walls on the main floor. I puzzled for years over what type of insulation would work, in terms of access, R-value, moisture issues, and ease of installation.

In the end, having become familiar with dense-packing techniques used by weatherization workers, I elected to use short-fiber fiberglass. I realized that I could access all areas of the walls by drilling through the window and door jambs (see Images #12 and #13).

It was a fairly tough prep job, but went smoothly once the insulation process started. We used high air pressure and we closed down the insulation gate to maximize throw and density. I was able to verify the throw of insulation fibers by checking the holes in adjacent window jambs while blowing the intervening walls. I’m confident that we were able to fill all the cavities except for the built-up header area over the windows. Interestingly, the infrared camera wasn’t useful on these high-mass walls. The bag count of insulation was on target.

My calculation was that we increased the R-value of the walls from R-5 or R-6 to R-12 or R-14. That’s not good enough, but is all that was possible unless we went with an exterior cladding system.

The most immediate change we noticed was that the house was markedly quieter, which was interesting, given the quietness of masonry houses.

Closed-cell spray foam for the basement walls

The basement walls are 18-inch-thick rubble stone walls with absolutely no cracking or signs of settling. There is some efflorescence on the lower walls in a couple of places which will be dealt with by regrading the exterior and improving the rain gutters.

In the basement, the floor joists sit on a 2×4 mudsill. There isn’t a rim joist, but rather two wythes of brick on the exterior side of the floor framing.

I’ve became convinced that there is some air infiltration through the brick rim and the stone foundation. The interior of the rim joist area and the basement walls was skinned with high-density spray foam: 3 inches of foam at the top, tapering down to 1 inch at the floor (see Image #14). In the near future, the interior walls will be framed with studs and then I’ll install unfaced fiberglass batts and drywall.

A new furnace

Judging from the age of the house and a blocked-off coal chute, the original furnace in the house was probably an octopus-type cast-iron coal furnace that used large ducts in a gravity feed arrangement. At some point, the original furnace had been replaced with a 1988 Lennox Type I furnace rated at 120,000 BTU/h.

The plenums were connected to the original registers with flex duct. The original floor boots were insulated with asbestos, so I donned my Tyvek suit and respirator, soaked the asbestos, and peeled off what I could. Then I painted on a coating of duct mastic over the remaining asbestos. I also sealed the boots to the adjacent subfloor with foam and caulk.

The Lennox furnace had a motorized damper on the combustion air and tested at 82% efficient. Normally I wouldn’t consider replacing it with a more efficient furnace because the payback just isn’t there. The older furnace, however, only ran about half the time at -20°F. Additionally, the supply air to the house was too cool and the flue pipe into the brick chimney was rusted. I began to suspect that the fan on the furnace was oversized and cooling off the heat exchanger too much.

A year ago I ran across a great deal on a 95% efficient gas furnace and couldn’t resist the challenge of my first furnace installation. The new furnace was rated at 80,000 BTU/h input rather than 120,000 BTU/h, a more appropriate size for the now insulated house. Because this was my first experience at furnace installation, I carefully read the manual and then laid out, starting with the biggest elements, the furnace location, sheet metal plenums, branch ducts, plastic flues, gas line, and electrical hook-up.

After setting the furnace in place, I had a local sheet-metal shop build new plenums and a new trunk line. After these were installed, I connected the rest of the ductwork which included some new metal take-offs, dampers, and fittings. The existing flex duct was then attached and sealed (see Image #15). I had a licensed plumber install the gas line and I tied in a new circuit from the breaker box.

The furnace has run flawlessly since the initial start-up. It is noisier than the old furnace, but the supply air is much warmer. I was surprised that the new furnace still only ran about 50% of the time when outside temperature was -20°F. I should have considered an even smaller furnace.

I also had discovered that my water heater (an atmospherically vented gas-fired model) failed the worst-case depressurization test — it backdrafted. The water heater had a 3-inch metal flue that had been vented into a 6″x8″ unlined brick chimney, and I expected that its draft would be even worse once it was “orphaned.” Installing a sealed-combustion furnace should eliminate some of the competition for combustion air in the basement, but the water heater would have trouble establishing draft by itself in the cold unlined brick chimney. To improve the draft, I installed a 4-inch flue liner.

Improved comfort

After each one of these chapters, Laurel and I have felt a noticeable improvement in comfort, both summer and winter. The house is much quieter too.

We’ve been able to eliminate all four of the upstairs ceiling fans and the use of a window air conditioner in the summer. Livingston usually gets a week or so of hot weather in the summer when the outdoor temperatures are in the high 90s or lower triple digits. Usually nighttime temperatures fall by 20 to 30 degrees. By conscientiously opening and closing curtains and windows, the house stays delightfully cool all summer.

We sometimes do get a night or three when it doesn’t cool off at night and we have to sleep with just a sheet. This summer, we had a week of mid 90s weather, reaching a peak of 105ËšF. The highest indoor temperature was 76ËšF. With better airflow through the house, I think that we could do even better.

In the winter, we’ve found that the house feels warmer after all these improvements. We are still running the setbacks on the new programmable thermostat, about the same as we did with the old Honeywell, and leave the heat off upstairs, so I think that we haven’t changed our behavior or expectations with all the changes. I do hear less grumbling from the girls about the cold, and they use the upstairs bedrooms more during the day. Laurel and I do leave a bedroom window cracked all winter, so that probably affects the house performance a bit.

Quantifying the savings

Magazine articles describing new innovative green homes have always driven me crazy. Pretty pictures, construction drama, cool equipment, and bragging rights. Very rarely are energy predictions correlated to actual energy usage. Rarely is energy savings quantified in any way.

I’ve been pretty anal about record-keeping, collecting utility bill data in a spreadsheet every month since we bought the house in 2005. I track electricity and gas consumption (see Image #18) and energy costs, average outdoor temperature, and Heating Degree Days. From all of this, I calculate ratios and make graphs. I’ve also kept track of my construction expenses (see Image #17) and calculated my cash flow (see Image #19).

In eight years, we’ve reduced space heating requirements by 60%, electric use by 45%, and air leakage by 63%. This past winter, I installed a PV system that is slightly oversized, so now I only pay the monthly service charge. With that addition, utility bills have been reduced from $1,960 in 2005/2006 to about $600 in 2015/2016.

Factoring in some energy inflation, I project that I will save around $31,000 in 20 years on an investment of $5,520 just for the space heating improvements.

A good return on our investment

My approach to energy conservation on my own house has been conservative. I’m pretty hard-core about saving energy, but very cautious about spending money if there isn’t a return on my investment. I’ve done very well financially on this project with this approach. It did help that we started with a house that was almost totally uninsulated, so the percentage of energy savings was significant. We also haven’t gone overboard by replacing windows or cladding the exterior walls. The best part is that we live in a great old house which is comfortable and affordable.

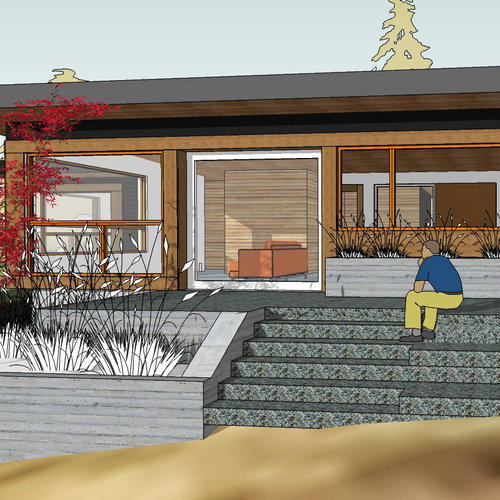

So what to do now? The kids are grown. The house is finished and much too big for the two of us. I guess it’s time for a mid-life crisis. Maybe I’ll start looking around. I’ve always had a roving eye. Those mid-century moderns look pretty sweet.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

12 Comments

Mid century moderns DEFINTELY have their challenges too.

Houses are never really "done", are they? Most houses that will be around in 2050 are already standing, and it's good to take on this kind of energy & comfort rehab. Good work!

Mid-century modern home are often real energy pigs. I have some in-laws who recently bought a gorgeous 1960-ish modern house who ended up having to do extensive re-work to make it fully liveable, which I may be blogging about soon (pending their permission). It still has plenty of work to be done, but it's had an amazing transformation in the 18-24 months they've had it, while preserving its architectural character.

Older Homes = MONEY

Never attach emotions to a piece of real estate. Real Estate is what it is....an asset and with that asset their are advantages and disadvantages to it. Older homes are especially a drain on cash flow and you better have a good idea of the comps in the area to get back what you put into it in terms of improvements. If you want to have a modern energy efficient home, then build one using all the modern technology there is out there without exceeding your comp value in the area you will be building. Falling in love is for people and puppies.

@eugene

"If you want to have a modern energy efficient home, then build one using all the modern technology there is out there without exceeding your comp value in the area you will be building."

Where is this mythical place? Is it within 20 miles of the nearest town? I'm willing to travel. ha! ;)

Falling in love

Rely to Eugene:

Some would say that the world needs more love; love of the earth, of our communities and family. In my case, living in an older home, centrally located, has real social and energy advantages. I can walk to downtown, the grocery store, the library, the schools and the bars. Plus,I'm making real good money just on the cash flow of my energy retrofit. I don't know that I'll recoup my investment in appraised value, but who cares. I've got 20 years or more living in this wonderful, old house.

A home is more than a financial instrument.

Seriously! If you're planning to live there for awhile, there's more to the art of dwelling than contemplating resale values, as Jim Baerg's project amply demonstrates. Treating it purely as a financial instrument is for short times and people who don't know how to live. A glitzy bathroom or kitchen makeover may improve the resale value relative to the neighborhood comps, but it doesn't improve comfort the way fixing the thermal deficiencies does. That's fine if your goal is to flip it, but it's not how to live.

All older housing (and many newer houses) need thermal upgrades to become both more comfortable AND sufficiently low carb to meet greenhouse gas emissions goals. The staging of those upgrades needs to be cost-optimized and a priority order established, but it need not break the bank the way an instant full-on Deep Energy Retrofit might.

Similarly, analyzing thermal upgrades simply on a net-present value of future energy cost savings basis also misses the point. It's also buying comfort & resilience, which are nice (if less visible) features to have in a house you intend to LIVE in.

Knocking a house down and starting over is resource & cash intensive too, and only rarely the "right" solution.

home costs

We have been planning a new super energy efficient home for the last 2 years, and have been constantly readjusting the size and details to try to make it affordable. We have finally decided that we don't want a bare bones cottage and can't afford what we really want, so we are staying in our 100+ year old farmhouse and doing a few more updates. Our hoped for 2000SF house (almost half of the floor area would be my wife's workspace for her fiber crafts) would cost us a couple of $100K more than our existing house is worth, perhaps twice what the larger new homes in a nearby development are selling for. I too would like to find this mythical place where an ordinary person can afford to build a house remotely fitting their dreams.

Great example of a PGER

A great example of a pretty good energy retrofit can be done at low cost! Lots of painstaking labor there, of course, but it would be hard to be motivated to do that work if you didn't love the house. So the love saved you money, rather than draining it as comment #2 warn about.

One question--do you have soffit vents, and if so, how do your ventilation baffles connect to them? It seems like that's tricky with the sloped ceiling sections.

Soffit Vents

Yes, I'm completely connected from soffit to ridge. I used the cardboard baffles at the soffit and at the sloped ceiling sections. The latter area seemed like a problem, but actually turned out to be an easy install. After the baffles in the sloped section were secured, leaving about 4.5 inches for insulation, the insulation contractor dense packed the sloped rafter sections. Those ceiling areas only have about an R-16. In my old age, maybe I'll fur them out on the inside and re-sheetrock.

I've come to think that attic ventilation isn't always critical, especially if the ceiling is well sealed, (Ours tested out at 46 Pascals between interior and attic when running the blower door). Bill Rose writes that the 300:1 ventilation ratio in the codes is just a historical artifact with little basis in the real world. Also, in our windy climate, ridge vents tend to create negative pressure inside the attic, so I put more soffit vents and less ridge vents in than the code requires.

@Jim Erdman

I gave up as well.

Insulation between masonry wythes

I believe the accepted wisdom is that the cavity between two wythes of exterior masonry should be available for drainage when water gets past the outer wythe of masonry (brick masonry is generally not waterproof). Rigid insulation is often placed (installed during construction) between wythes, but a gap for drainage between the insulation and the masonry should remain. I wonder whether totally filling the gap with blown-in fiberglass may end up causing you a problem if the fiberglass gets soaked with storm water from leakage through the brick.

Venting brick wythes

Reply to Carl Mezoff;

I worried about this a lot too, hence the several year interlude after the attic work. Montana is very dry, about 12 inches/year, half as snow. The cold winters make for high vapor pressure to the exterior. The bricks are very soft and easily absorb water but we very rarely get sideways rain and I have good gutters. My interior humidity is commonly 35% during the winter.

I looked at every insulation known to mankind from an installation standpoint, thermal performance and moisture control. In the end, I went with dense packed short fiber fiberglass. Because it is hydrophilic, it should wick moisture out, and the exterior brick has a very high perm rating.

This solution isn't for every climate, but it seems to be working here. Absolutely no sign of moisture or frost.

greetings from the Ohio weatherization program

Hi Jim: Also a fellow lapsed architect . . . just wanted to thank you for the excellent documentation of your efforts. I'm passing your post around to my co-workers with Ohio's state weatherization program, including some contacts with Ohio's training center. It's always good to compare notes with other weatherization warriors, and although we don't go so far as to insulate double-brick walls or spray foam the full height of basement walls (ouch) everything else was pretty comparable. And the cost/savings info is great . . . nice to have as an example of how the program works. Hope you get time to enjoy your new digs. But then again, a Prairie School or Eames style might be too much of a siren call to ignore!

Log in or create an account to post a comment.

Sign up Log in