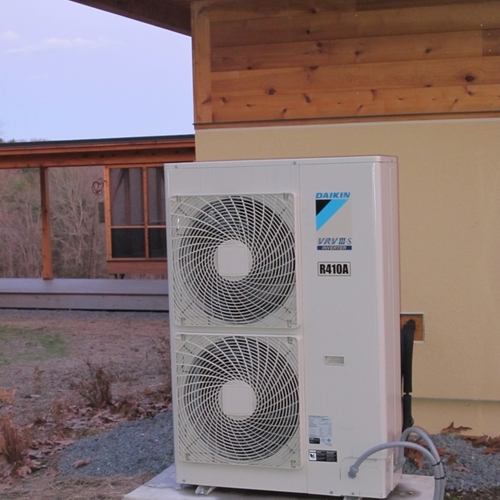

Image Credit: Proctor Engineering Group

During the last week of June, many major U.S. news outlets sent reporters to Arizona to issue updates on the area’s extreme heat wave. Outdoor temperatures hit 119°F in Phoenix. Some airplanes were grounded because the hot air was too thin for small jets to take off. Car steering wheels were so hot that some drivers wore oven mitts. Vinyl records delivered by mail arrived warped. Emergency room physicians reported an increase in burn cases: hands were burned when people touched their cars, and children’s feet were burned when they went barefoot outdoors.

The reports from Arizona conjured apocalyptic images of a science-fiction future — one in which rising outdoor temperatures make it difficult for humans to leave the safety of an air-conditioned building.

The question arises: Can typical split-system air conditioners handle these conditions? Or will extended heat waves require air conditioner manufacturers to design new types of equipment?

The compressors will still work

To get answers to my questions, I turned to John Proctor, the president of Proctor Engineering Group in San Rafael, California. Proctor is a professional engineer and a nationally recognized expert in residential air conditioning systems.

The short answer to my question is that the outdoor units (the condensers) of split-system air conditioners should have no problems handling a heat wave in Arizona. If homeowners feel hot during a heat wave, the problem is rarely due to a condenser or compressor that can’t handle high outdoor temperatures. Instead, problems typically arise from installation problems (for example, restricted air flow to the outdoor unit or poorly designed duct systems).

“If you have an old compressor that is unhappy — one that is getting ready to go out — what happens is that at high temperatures, the head pressure…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

21 Comments

SW and Extreme Temperatures

Would it help in the SW to shield the condensing unit from the sun with a "shed" roof, with enough clearance for good airflow? (Maybe a flat roof to follow architecture)

I know that condensers installed on the West and North side of the houses run better, or it appears to!

I can just see those diffusers full of leaves and junk in no time! ;-))

Multiple sources I see

Multiple sources I see indicate that compressor oil temperature isn't an issue until > 300F.

AC Diffuser

I like that idea. Now I need to find a vane anemometer to measure the increase in flow. I think I can do this.

Lucy

Vane Anemometer - not cheap

Oh well. Not sure about the vane anemometer because they are not cheap. I may have to go with using my hand to estimate air flow.

http://www.davis.com/Category/Rotating_Vane_Anemometers/51590

There's a bit of scattershot info herein

Info in this article is kinda all over the place in terms of actual operating conditions and reality. A few examples:

1) Annual checkups - While John Proctor is right that some companies troll for unneeded service work under the guise of periodic preventive maintenance, it must be acknowledged that complex systems operating in severe environments are vulnerable to deterioration. When do you want to find out that the capacitor that has drifted out of spec will no longer start your outdoor fan or compressor...during spring maintenance or during an outdoor heat wave?

Disclaimer - I run an HVAC company. We check our clients' systems semi-annually using an 80 point checklist designed to stave off unplanned failures and expensive repair costs. One improperly secured wire can cause the system to blow its refrigerant charge or burn out the compressor. Pay us now or pay us later...your call.

2) "No problems up to 125°F or 130°F" Maybe or maybe not. At that outdoor air temperature AC compressors are at the ragged edge of design gas discharge pressures and temperatures as well as compressor motor current. If outdoor unit air flow is maintained as to volume and the installation is such that the unit won't "rebreathe" its own discharge air, it should keep running, albeit at a significant reduction in capacity and efficiency...both will drop by 1/3 or more compared with ratings at industry-standard 95* ambient.

Then again, competent system specifiers in the desert southwest should already have applied correction factors for operation at temps well above 95*F. It's called Manual S, and this isn't the first year Phoenix has been well above 95*F outside.

3) The Funnel. I'd sure like to know more about that. I highly doubt it increases air flow through the outdoor unit since it must by definition introduce a bit of restriction to air flow. What it likely does do is channel widely swirling discharge air further away from the system so that it is less likely to rebreathe its own discharge air when it has been installed in a location confined by vegetation, walls, fences and / or overhangs.

4) Capacity dropoff - there is no magic temperature such as 105*F; it's actually a continuum. Systems are rated by national standard at 95*F. All of them have progressively more capacity at outdoor air temperatures below 95*F, and progressively less at temperatures above 95*F. Efficiency follows the same track. Again, I refer readers to Manual S, the long recognized procedure for sizing HVAC equipment that takes into account actual outdoor air temperatures.

Response to Armando Cobo (Comment #1)

Armando,

Q. "Would it help to shield the condensing unit from the sun with a shed roof?"

A. Basically, no. We've addressed this question many times on GBA. I addressed it, for instance, in a 2014 response to a Q&A post titled Does an AC compressor located in full sun work harder than one located in the shade?

The following year, in 2015, GBA blogger Allison Bailes wrote an article on the topic called How Much Will Shading Your Air Conditioner Improve Its Efficiency?

Q. "I can just see those diffusers full of leaves and junk in no time!"

A. Good point. I imagine that anyone who installs this type of diffuser will need to perform, at a minimum, an annual cleaning at the beginning of the air conditioning season (February 1st in Florida, and July 10th in Vermont). In most cases, the condenser fan will probably blow out the occasional leaf that falls into the funnel during the summer.

Response to Curt Kinder (Comment #5)

Curt,

Thanks for you detailed and helpful comments. The fact that the three experts I interviewed are "kind of all over the place" and that their advice amounts to "scattershot info" is an accurate representation of a few differences of opinion from engineers who are experts in the field. You have added a fourth voice, at times congruent and at times divergent. It isn't unusual to find that engineers don't always agree.

cheap anemometer

Expensive anemometers are not cheap, but cheap ones are cheap. Here's one for $14.

https://smile.amazon.com/ANGGO-Portable-Handheld-Anemometer-Thermometer/dp/B01EJJ8WB6

I am not particularly recommending that one, but am just noting that there are cheaper options.

I also want to note that just having that instrument doesn't make measuring airflow easy, as the flow varies across the surface, and the reading of the meter depends on things like turbulence in the air as well as the actual flow. But you'll probably get a more accurate assessment than with your hand.

Anemometer and outdoor unit air flow

Most competent HVAC companies take a stab at measuring system performance in the course of PM procedures. It is common to measure return and supply air temps and also report the delta. A properly running system in cooling mode will typically exhibit an indoor Delta-T in the range of 18 - 22 *F

Our techs go a step further and calculate airside temp split across outdoor compressor section. Typical values are 8 - 12*F, with higher SEER units coming in on the lower end of that range. If the entering air temp is above ambient outdoors, then the system is rebreathing outdoor air, likely owing to adjacent walls, fences, overhangs, vegetation or fratricide (another unit operating nearby)

In round numbers, the outdoor fan moves approximately twice as much air as the indoor air handler blower. We constantly stress the necessity of attaining proper air flow on both sides, indoor and outdoor, of a split heat pump system.

Assessing the efficacy of a retrofitted funnel (picture looks quite like a galvanized sheet metal agricultural tub with bottom cut out) should be fairly easy:

Operate the system continually for 15 minutes to achieve steady state. Attach good quality AC current meter and high side refrigerant pressure gauge, preferably a modern digital manifold.

Note readings, attach funnel, monitor readings. If compressor amps fall along with high side pressure, winner winner chicken dinner. If OTOH, current and pressure rise, remove funnel.

Response to Kurt and Lucy

The diffuser absolutely works. We have tested it many times. We incorporated it into our two high temperature prototypes. it does not increase restriction, it does increase airflow. The science of diffusers is well known and used for years and years. You do not need to measure the increase in airflow unless you are a energy nerd like me. My recollection without going back to the textbooks is that the diffuser helps change the pressure increase across the fan into velocity rather than providing a "backpressure" on the fan. What is more the watt draw per 1000 CFM drops. If you want to see some of the tests go to https://www.proctoreng.com/dnld/01140.pdf Table 21. Also the performance of an air conditioner degrades as the temperature increases nothing magic about 105.

I find figure 47 interesting

I find figure 47 interesting - small differences in charge caused large differences in efficiency.

Also figure 28 - thermostat hysteresis has a significant effect on efficiency?

Response to Jon R

Jon,

I have reproduced Figure 47 from Proctor Engineering's paper (Energy Performance of Hot, Dry Optimized Air-Conditioning Systems) below.

Your reference to Figure 28, however, is a little confusing, since Figure 28 depicts a tube axial fan. The fan illustration doesn't appear to have anything to do with thermostat hysteresis.

.

More on diffusers

I just received an email from Van Baxter (the researcher from ORNL).

In his email, Baxter noted, "Nice article and interesting commentary. Just goes to prove that engineers are a lot like economists: if you ask three of three of us for an opinion on a given issue you may likely get >3 opinions. I do agree with Dr. Proctor about the diffuser. Such a device will absolutely improve the performance of the outdoor unit fan."

A challenge to GBA readers

Who wants to be the first reader to send us a photo of a newly installed home-made diffuser? I hope that someone takes on the challenge -- perhaps next weekend.

DIY diffuser

Diffusers piqued my curiousity...it just now occurs to me that many, if not most or even all new commercial VRF system outdoor sections feature discharge air diffusers. Those appear to be hyperbolic, rather than straight sided funnels.

There's probably something to that, given that cooling towers sometimes incorporate a similar feature, and cooling tower performance very much depends on maximizing air flow for a given fan power input.

Engineering opinions are converging!

It's nice to see that the herd of cats can agree on a few important points.

Whoops, figure 48 (and table

Whoops, figure 48 (and table 23), not 28. Which I interpret to show that if you don't need the latent capacity, it's efficient to turn it into sensible capacity by running the fan after the compressor stops. And run short cycles so you do this often. Maybe it's better to just run a humidistat controlled humidifier in the house?

Not living in a desert, I typically need all the latent capacity I can get. So my question is "what effect does a thermostats "cycles per hour/swing/differential" setting have on AC efficiency?"

Here's Figure 48

Figure 48 from the Proctor Engineering paper.

.

Short cycling = bad.

..."And run short cycles so you do this often"

That would be bad - it takes 10+ minutes (some say 15-20) for a split heat pump to get to steady state conditions, before which efficiency is poor. It's also very hard on the compressor to short cycle - windings overheat, insulation degrades. Home HVAC systems all use hermetic compressors - unrepairable, and very expensive to replace.

Be kind to your system compressor, unless you like giving your boat payment to your friendly neighborhood HVAC contractor...who probably likes boats too!

Comment 14

Martin,

I took a look at my RSL3H series Fijitsu mini splits to see if I could take advantage of this. To my surprise they already have a short integrated diffuser. It's only a about 2 inches deep as an estimate, but it's good to see manufactures aren't leaving something so simple and easy on the table.

Mitsubishi City series

Mitsubishi City series compressors have substantial built-in diffusers.

http://www.mitsubishicomfort.com/sites/default/files/img/feature/timeline2003.jpg

The lowest possible impedance profile for easing the pressure difference is a logarithmic arc (the same shape as with ends of brass musical instruments, police megaphones, and antique Victrola record players) but any reasonable approximation helps, even a cone section (such as the cheap un-powered fan megaphones at football games or a crew team coxswain's megaphone.) The DIY version is a cone section, easy to build, but clearly not the highest possible performance.

.

Log in or become a member to post a comment.

Sign up Log in