It’s time to revisit one of my favorite topics: air conditioner sizing. Many contractors use rules of thumb to decide what size cooling equipment to install. Usually, the rule is based on the amount of conditioned floor area, and contractors in many areas generally use the rule of 1 ton of air conditioning capacity for each 400 to 600 square feet of floor area. The rule is usually specified in square feet per ton (sq. ft./ton).

The rule doesn’t account for the window type, orientation, or overhang. It doesn’t account for airtightness or the insulation levels. It doesn’t account for any of the features of the house that actually have an impact on how much cooling it needs. It just scales the air conditioning system to the size of the house.

Rules of thumb vs. load calculation results

First, a quick note on the numbers. When we talk about square feet per ton, higher numbers mean lower cooling loads or lower air conditioner capacity. Cooling loads and air conditioner capacities are actually given in the amount of heat gained or lost per unit time. In the US and Canada, it’s mostly BTU per hour. In the rest of the world, it’s kilowatts. Sticking to BTU/hr, we can divide the cooling load by 12,000 to convert to tons.

Then, to factor in the size of the house, we could divide the load or capacity by the floor area, but the numbers would be tiny. For example, a 3000-square-foot house with a 3-ton air conditioner would have 3 ÷ 3000 = 0.001 tons per square foot. By inverting, we get a nicer number, 1000 square feet per ton.

What we find is that most newer homes—even in hot climates—have square feet per ton numbers significantly higher than 400 to 600. Even 1500 square feet per ton or higher isn’t unusual. That means a contractor using 500 square feet per ton is installing an air conditioner that’s three times larger than it should be. In a 3000-square-foot house, for example, the rule-of-thumb installer might put in 6 tons of capacity. Using the Manual J and S protocols, they probably would find the house needs only 2 to 3 tons of air conditioning capacity.

My rule of thumb is 1000 square feet per ton for newer houses. I don’t mean that’s how I do air conditioner sizing. That’s just my quick check to see if a system might be oversized. If that calculation comes out close to 500 square feet per ton, I assume the installer didn’t do a load calculation, or if they did, they fudged the numbers. If it’s 1000 square feet per ton or more, it may be okay. But that applies to the above-grade parts of a house. Basements are often closer to 2000 square feet per ton—or higher!—for newer houses.

Load calculation data from our jobs

In a 2016 article, I showed some of our load calculation data from our HVAC design jobs. I pulled out 40 homes in hot climates and found the average cooling load was 1431 sq. ft./ton. I don’t recall how I filtered the data to exclude cold-climate homes. Also, I didn’t look at the equipment sizing data. Recently, though, I went through our jobs from 2021 and redid the analysis.

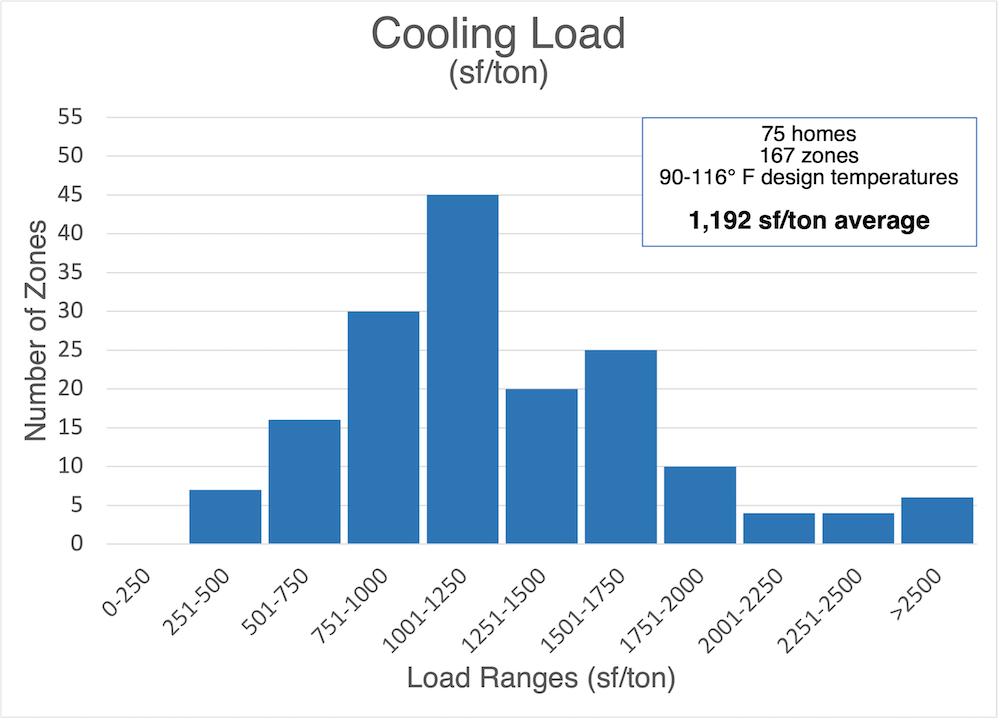

The graph below shows the breakdown for some of the load calculations we’ve done at Energy Vanguard in 2021. The data come from 75 homes, and the numbers plotted here are for the 167 individual zones in the houses. All the homes included here are in hot climates, which I defined as having an outdoor cooling design temperature of 90°F or higher. We use Wrightsoft’s RightSuite Universal to calculate the ACCA Manual J loads.

Of the 167 zones, only 53 came in lower than 1000 square feet per ton. A mere 20 zones were below 700 square feet per ton. That means only 12% of the zones in this group might have been close to having right-sized cooling equipment using the 400 to 600 square feet per ton rule. The average load for all 75 homes, as you can see on the chart, was about 1200 square feet per ton.

Equipment sizing data from our jobs

Now let’s look at the actual air conditioner sizing numbers. Most of the time, the air-conditioner capacity will be larger than the cooling load because of two things. First, you have to meet both the sensible and latent cooling loads, not just the total load. Second, air conditioner capacities don’t always line up perfectly with the cooling loads.

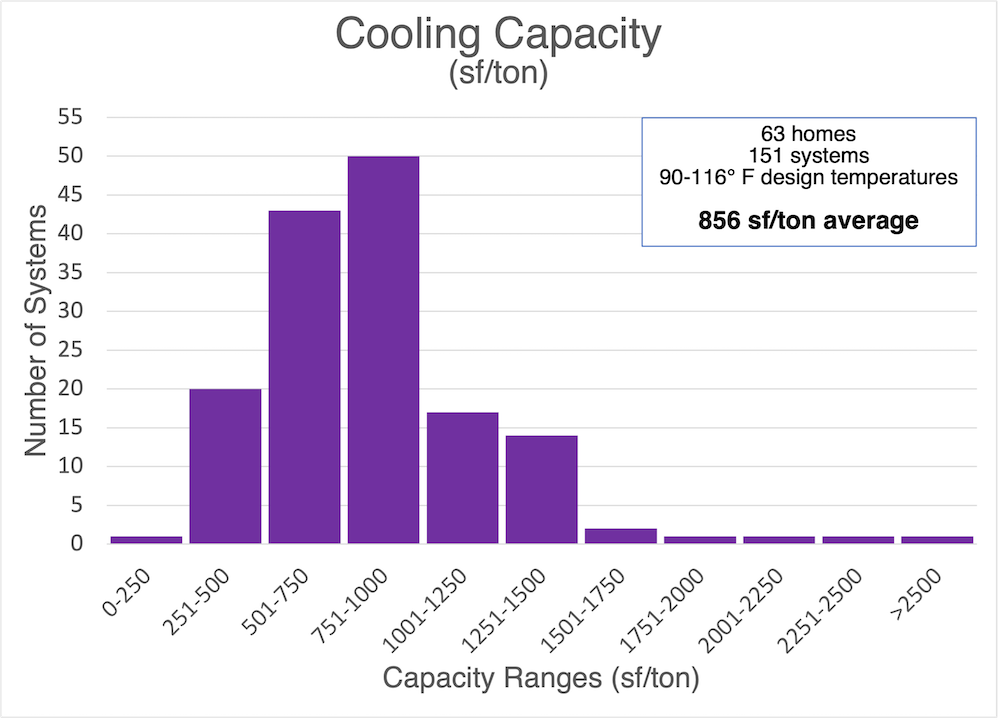

Using the same group of homes as above, I’ve plotted the actual air conditioner capacity we specified. The graph below shows the results of that analysis. This time there are 63 homes included in the data. (It’s not 75 because some of those in the previous chart were jobs where we did only the load calculation and did not select equipment.)

In those 63 homes, we selected 151 individual heating and cooling systems. As you can see, the columns have shifted to the left here, indicating that the air conditioning equipment we chose was larger than the loads. That’s why the average capacity of the systems we selected was 856 square feet per ton, making our average capacity 28% higher than the average cooling load (1192 square feet per ton).

But there’s a catch. I used the nominal capacity for the systems we selected. The actual capacity from the manufacturers’ expanded performance data would show less capacity. The real square feet per ton number here would probably be about 1000. And remember, even right-sized systems still will be oversized because Manual J loads are 10 to 20% higher than the actual cooling loads.

Air conditioner sizing key points

We can summarize with a few key points here.

1. Using a rule of thumb like 400 to 600 square feet per ton will work for very few houses. Sizing an air conditioner to that metric will almost always result in an oversized air conditioner. Sometimes grossly oversized.

2. Actual cooling loads found by using the ACCA Manual J protocol are much lower than the rule of thumb numbers. That means the square feet per ton numbers are higher.

3. Actual air conditioner sizing is also much lower than the rule of thumb. In the batch of jobs I analyzed, we’re at 856 square feet per ton.

4. Our air conditioner sizing numbers are actually better than shown above because I used nominal capacity instead of finding the actual capacity.

5. Another factor that makes our air conditioner sizing larger is that in most of our HVAC design jobs, we specify variable capacity equipment. Oversizing doesn’t hurt as much with that type of equipment because it can ramp down to meet the load. (Just be sure you know the turndown ratio of the equipment.)

Designing an HVAC system starts with proper sizing. Look at the square feet per ton number you get to see if you’re in the ballpark. If the number is less than 1000 square feet per ton for newer homes, either the number is wrong or the house isn’t as efficient as it should be.

_________________________________________________________________________

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has a book on building science coming out in the fall of 2022. You can follow him on Twitter at @EnergyVanguard. Images courtesy of author.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

3 Comments

Now I have more Questions than Answers. It’ll be interesting to learn what type of roof and wall assemblies were used in those home averages, what ACH50, what glazing ratios, etc., etc. Seems to me, you have a great opportunity to chart the equipment sizing to quality of building envelope. I call that showing the simple truth on a graph.

What are the specifications of houses with ≤250 sf/ton? What are the specifications of houses with ≥2500 sf/ton? How about all of the houses… hummm!

Too late for a new chapter in your book? Maybe a new book?

Using a modulating 1-ton Midea window shaker (essentially a "mini-split in a can") mounted in the loft-office window at the top of the stairs in my ~2400' 1920s vintage house, as long as all of the interior doors stay open it covers 100% of my 1% cooling load (local 1% temperature bin =83F) at an average interior temp in the mid-70s F.

That's a ratio of ton per 2400' at design condition.

Without the window unit on, running the ludicrously oversized 5 ton ducted central air the duty cycle never exceeds ~50% even when temps are in the mid 90sF outside (like right now), implying a load ratio of a ton per 1000' at outdoor temps 10F or more ABOVE the 1% design temp.

Within the next couple of years I'm intending to install a 3/4 ton compact duct cassette to heat & cool the upstairs (~400 square feet), and a modulating 1.5 ton full sized air handler to replace the hydro-air zone on the first floor (about 1000 square feet), which is plenty of cooling power. All but one of the other rooms (heated with hydronic radiators or radiant floor) CAN be cooled with the 1.5 tonner, with only one room lacking sufficient duct capacity to fully cool the space. But if the doors to that space are left open it stays within 5F of the thermostat setting when it's north of 90F, despite the mediocre air flow on that duct.

“as long as all of the interior doors stay open”… could you use some room-to-room ventilation fans? Broan-Nutone, AirShare and Tjernlund comes to mind.

Log in or create an account to post a comment.

Sign up Log in