Image Credit: All photos: Home Energy magazine

Image Credit: All photos: Home Energy magazine The collectors, each made up of 300 feet of ¾-inch poly pipe mounted to a steel bracket. The Uponor PEX tool and tubing used to connect to the house’s plumbing. PEX is about 4 times quicker to install than copper. Zak Vetter, who is over six feet tall, and the 105-gallon Marathon tank. Goldline GL-30 solar controller and mechanical thermometers. System performance at the spring equinox. System performance at the winter solstice, when it produced water ranging from about 110°F to a little over 140°F. A comparison of winter and spring output, showing the exit temperature of each of the four coils, plus the water temperature at the tank exit.

Zak Vetter contributed to this article, which originally appeared in Home Energy magazine. It is reprinted by permission.

Way back in 1978, I installed my first solar water-heating system. I continued with solar thermal, installing new systems until tax credits expired in 1986, and I kept nearly all the local systems up and running for years after that. It became painfully obvious to me that simplicity is essential for the durability and longevity of any solar-thermal system. Complex systems just die young. Back then, the holy grail of solar thermal was to come up with a system that would cost $1,000 — which nobody ever really succeeded in doing. These days, you expect to pay $6,000 to $10,000 for a solar hot-water system, installed.

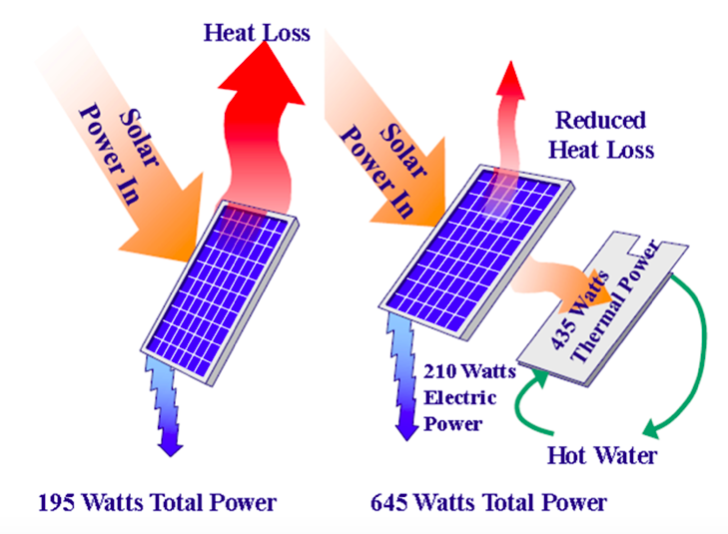

My friend Martin Holladay published an article in March 2012, entitled “Solar Thermal Is Dead.” He generated a lot of discussion with that article, including some dissent, so he published another article in December 2014, entitled “Solar Thermal Is Really, Really Dead.” Martin looked at solar-thermal prices and compared them to using PV and a heat pump water heater to do the same job. After doing the math, PV and a heat pump appeared to beat solar thermal for water heating.

But often the answer you get depends on your assumptions, and in designing and building this system we chose to challenge some of those commonly held assumptions. For one, heat pump water heaters are new enough that we don’t really know how long they will last. For another, there are great advantages to installing a system that, while not protected against freezing, will not be damaged by freezing. These are reasons to continue to explore how to make simple solar thermal work.

The project

Enter Zak Vetter. Zak asked me to help design and install a solar hot-water system for his home near Carmel, California. It’s a roof-mounted system on a building that combines living space and shop. He had established a simple set of goals for the project:

- Greatly reduce or eliminate the need for off-site energy to provide all the hot water desired.

- Build a system that works well in less-than-ideal conditions. This means that even on a cloudy day, most (or even all) of the hot-water demand is met by the solar energy collected and stored in the system.

- Build a system that requires nearly zero maintenance.

I had never worked with such a demanding list. Many assumptions go into designing and building a traditional solar-thermal system, and these got challenged by Zak’s goals. Here are some of the assumptions we typically work from:

- Solar can provide, at best, 75% of your water heating.

- With freeze protection, solar is complex.

- Overheating is a big problem for solar.

- Installing solar thermal is tricky.

- Solar-thermal systems need yearly maintenance.

Design rules also involve assumptions:

- We want the most efficient collectors.

- Sizing a system for winter will cause overheating in summer.

- Parallel piping gathers the most Btu.

- Storage tanks should not be oversized since this will create stagnation problems.

- Freeze protection dictates system design.

Clearly, Zak’s goals didn’t line up with the standard assumptions. But I’m glad he challenged convention, because ultimately we built a system that costs less and performs better than any solar-thermal system I know of. The system cost right around $4,000 and provides 95% of annual hot-water Zak’s family needs. Someone good with their hands could do the same job for around $3,000, if they built their own collectors.

The collectors

Following is the thinking that got us there. Wanting efficient collectors would have forced us to build a more complex, expensive system, to prevent freezing and overheating. So instead, we used really inefficient collectors! These are just coils of ¾-inch polyethylene tube under an acrylic glazing (see Image #2, below).

There is no insulation in the collectors, so they cannot overheat and are unlikely to be damaged by freezing. The top temperature we’ve measured in summer with no water flow is 170°F in the collectors, and they have frozen many times without a problem. This type of collector has been tested in San Jose, California, for 16 years and no troubles have surfaced. Essentially, they are pool collectors, modified to produce domestic hot water simply by adding glazing. They are commercially made by Gull Industries in San Jose, California.

Each coil measures 26 square feet. Another benefit of using “inefficient” collectors is that we eliminated the need to run copper pipe to and from them, by running PEX tubing instead. With traditional copper collectors, which can stagnate in the summer sun at up to 400°F, PEX tubing would melt pretty fast. But we were able to use poly pipe and PEX for nearly everything, simplifying the job even further (see Image #3, below). We purposely oversized the system, so it could coast through periods without sun and recover quickly when the sun returns.

The tank

The tank was another consideration. Normally, with any glass-lined tank (nearly all tank-type heaters in the United States are glass lined), you want to turn over the volume of the tank daily to prevent stagnation and odor problems. Turns out the anode that comes with all glass-lined tanks generates hydrogen gas, which some bacteria really like. We got around this by installing a 105-gallon Marathon tank by Rheem (see Image #4, below). This is a nonmetallic tank than needs no anode, so the water does not become aged, or contaminated, by slow turnover. The benefit of this much storage is that the system can continue to deliver hot water during sunless days.

One other benefit of the Marathon tank is its insulation. It has 3 inches of foam, and the literature says that it loses only 5°F in 24 hours. Our data logging suggests that it’s more like 6–8°F in our situation, but still, not bad. Insulation was something else we played with.

Pipe insulation seldom comes really thick, yet keeping heat loss down increases the actual solar fraction and reduces the amount of backup energy needed. So we decided to double up on the insulation wherever possible.

This is ¾-inch PEX pipe with two layers of insulation, for a total wall thickness of 1½ inches. It looks like one big pipe when installed.

Solar water heaters are normally designed as one- or two-tank systems. One tank is better, if you can make it work, as there is less equipment from which to lose heat. These days, this can only be readily done with electric backup. So another thing we did was to disconnect the lower element in our single tank and use only the upper element for backup. This prevents the electric heat source from competing with the solar one. We wired it at 120 volts rather than 240, so there was no need to do anything more than just plug it in. It does take 4 times as long to heat at half the voltage, but Zak wanted a good test of the solar. The system was installed in November 2014, and he has yet to use the backup!

The controller

The system is managed simply with an off-the-shelf Goldline GL-30 solar controller (see Image #5, below). It measures the temperature at the solar collector and at the bottom of the tank. It compares the two and, when the collector is sufficiently hotter, turns on the pump. The control has adjustments for fine-tuning this set point. Fortunately, we do not need the control that protects against freezing or overheating.

The system was simple to install. If you look just at installation time, it took only six person-hours, which is very fast. In the good old days, a fast installation used to be three guys and one long day, or about 24 person-hours. This system went in so quickly for several reasons:

- We used PEX and polyethylene tubing.

- We assembled the exposed connections with Sharkbite push fittings.

- The collector manufacturer supplied us with a prebuilt control station.

- The collectors were installed on the roof using only one central bolt.

- We had easy access to the underside of the roof.

- The collectors are somewhat flexible and lightweight.

- The 105-gallon tank is lightweight and easy to move.

System performance

Performance so far has been good. We’ve data logged at multiple points across the system in order to understand just how it’s working.

The term solar fraction is used to indicate what percentage of one’s hot water is heated by the sun. Done right, determining the solar fraction would involve measuring total hot-water use and subtracting the portion of water heating not provided by the sun.

We opted instead simply to notice when the solar-heated water was hot enough to shower with. If the stored water is around 105°F, it’s good for showering. When we say the system is producing 95% of the hot water, it means that Zak gets acceptable shower temps 95% of the time. It’s a quick, nonmathematical way of understanding generally how the system is performing. If we took accurate measurements to determine solar fraction, it would probably be higher than 95%. But because we consider anything under 105°F inadequate, we’re not taking credit for water that isn’t quite hot enough but is certainly well above groundwater temperature.

The graph in Image #6, below, shows the system during the first days of spring, when the system is making an admirable contribution to the home’s hot-water supply.

The graph in Image #7 shows the system at its worst. The vertical yellow bars represent periods of sunshine, and the vertical blue bars represent nighttime. Between the 21st and the 22nd you’ll even see rain! But note how just a few hours of winter sun on the 23rd boosts the tank by almost 20°F.

The other two graphs, shown in Image #8, illustrate the differences between December and March. In these graphs, we measured outputs from each collector to see if all four provided useful output. It turns out that the first two collectors gathered more Btu, but the second two collectors each bumped the temp up higher, so they really did help — particularly during the colder times of the year.

The relevance of this design

Clearly there are limitations on where this sort of system can be successfully installed. If these collectors are covered with snow, they might not function too well, so it would make sense to avoid areas that stay below freezing for extended periods of time. But because there is no metal piping in this system, it can withstand occasional freezing. And if tax credits are the main motivation for installing solar hot water, this system won’t do, because it isn’t yet certified by the Solar Rating and Certification Corporation. Still, this system should cost less then most other systems, even without the benefit of tax credits.

It’s clearly a good thing to bring fresh perspectives to solar water heating. By intelligently questioning old ideas and by using newer materials and hardware — such as the Marathon tank, PEX piping, and polyethylene collectors — Zak pushed us to do better than I had believed possible.

Larry Weingarten was raised on the Monterey Peninsula of California and has been self-employed for most of his working life. He got his general contractor’s license in 1982. Larry has written articles on water heating and energy for various trade journals; has taught about these topics for PG&E, California State Parks, Affordable Comfort, and others; and has recently helped create DVDs on these and related topics. In 2006, he finished building an off-grid home; designed to be very efficient, comfortable, and inexpensive, it was the 13th home to meet the 1000 Home Challenge, a competition for creating superefficient homes. He likes cats.

Zak Vetter contributed to this article. He was also raised on the Monterey coast, and has been self-employed for over ten years, repairing and teaching about computers. Since 2008, Zak has been learning about the wide-ranging world of energy efficiency while improving his own property. The solar water system in this article was inspired by a visit to Larry’s off-grid house, which demonstrated how much was possible with solar power.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

13 Comments

The 170F peak stagnation temp is fine...

...but the storage temp of 105F-ish is dead centered on the legionella growth hot zone.

It takes storage temps above 120F to pretty much stop (but not kill) legionella colony growth, and storage temps of 140F or higher (for substantial periods, if only 140F) to kill existing colonies.

In locations where it can go weeks or months below freezing outdoors (the cold edge of US climate zone 5 and colder) this type of hot water system isn't likely to be very useful, even if it's robust enough to survive the freezing.

For colder climates, Gary Reysa's PEX & radiant floor plate DIY flat plate collector system (operated at atmospheric pressure) would be more useful.

http://www.builditsolar.com/Experimental/PEXColDHW/Overview.htm

http://www.builditsolar.com/Experimental/PEXCollector/PEXCollector.htm

http://www.builditsolar.com/Experimental/PEXColDHW/TankConstruction.htm

The heat storage is in large unpressurized insulated tanks, with a the pressurized potable in a coil of PEX as the heat exchanger in which reduces the volume of tepid water storage, reducing the legionella risk somewhat.

Like commercially available drainback systems this too is a bit of a Rube Goldberg contraption, but it's comparatively cheap, and it works.

Inexpensive solar thermal system

I'd like to thank Larry Weingarten and Zak Vetter for sharing the details of this simple solar thermal system. Such a system shows a lot of promise, especially for homes in warm climates or locations without much snowfall.

This approach raises several questions. One question is whether the estimated cost of the system ($4,000) includes an adequate allowance for labor. I have emailed Larry for more information on labor costs; I'm still awaiting Larry's answer. Among the questions I'm interested in:

1. How many hours of labor did the homeowner (Zak) contribute to the project? Were these hours accounted for?

2. What labor rate did Larry assume for his labor?

3. In areas of the country where regulations require the participation of a plumber and an electrician, would labor costs be higher than those assumed by Larry and Zak?

As many GBA readers know, the National Renewable Energy Laboratory had a multi-year research project devoted to developing a residential solar thermal system with plastic components. As part of this project, NREL engineers worked with Fafco, a manufacturer of solar collectors for swimming pools, to develop simple plastic solar water heater. The Fafco Hot2o solar hot water system has been marketed in the U.S. since 2007. The main disadvantages of the Fafco approach are low water temperatures and limited lifespan.

I reviewed Fafco's Hot2O plastic solar collector for the May 2007 issue of Energy Design Update. Fafco promotes the plastic collectors as part of an inexpensive one-tank system. Here's an excerpt from the EDU review:

“[According to] Jay Burch, a senior scientist at the National Renewable Energy Laboratory, … 'If you have a one-tank system where the second [electric] heating element is not turned off, the system will perform poorly. Even if the thermostat is at low setting -- say, 105 degrees or so -- that’s still a pretty high starting point. If you can’t turn the lower element off, then you might as well just forget it. And if you do turn the lower element off, you take a hit in terms of available hot water when there is no solar availability. With a 40-gallon tank, you have about 35 gallons of more or less hot water. But if you turn off the lower element, you won’t have the volume of hot water sitting there, and on a cloudy series of days, you’ll only have 10 or 15 gallons of hot water. Consumers will have problems with that. Of course, if you have a gas water heater, you will always have to go to a two-tank system.'

"Other possible disadvantages to the Fafco Hot2o system:

- According to Fafco, the plastic collectors are expected to last only 12 to 15 years.

- Water circulating through an unglazed plastic collector doesn’t get as hot as water circulating through a conventional glazed collector. While glazed collectors can easily heat water to 190 or 200 degrees, “The Hot2o can heat water up to 150 degrees,” according to Doug Kohl, a representative from Fafco’s public relations firm.

- In some areas of the country, the limited heat that can be extracted from Hot2o’s collectors may not justify the cost of the electricity required to circulate water through the collectors."

After reading Larry Weingarten's article, I called up Tim Merrigan, the program manager for solar buildings at NREL, to discuss Larry's approach. "Larry Weingarten’s solar thermal system with plastic pipe falls into the DIY category," Merrigan told me. "It’s not like a contractor-installed system."

Merrrigan continued, "Solar pool heating manufacturers have been selling these plastic collectors for years. It is a valid approach. The systems are primarily sold in warm climate states like Arizona and Florida. The real issue in colder climates is wind -- wind and cold temperatures. The acrylic glazing helps address the wind issue. But in most locations, the acrylic glazing will eventually deteriorate. The primary advantage of this approach is the lower cost. When used for domestic hot water, these are really preheating systems. If Larry's collectors have acrylic glazing, that knocks the wind effect down. It will work for a while. The problem is material durability. Acrylic glazing is very susceptible to impact and hailstones.

"The reason to pursue the idea of collectors with plastic components is to lower the cost. But when you use polymers and polymer glazing instead of a copper, glass, and aluminum system, you are going to lower the performance.

"Fafco sells a DIY kit in a box for about $1800. The installed price with labor is closer to $3,000. At that price, it’s still hard to compete against natural gas. The cost has to come down still lower to compete with natural gas."

Thoughts, comments, and questions..

I agree that this does have climate limitations, but do we really need an all-climate solution?

5deg/day vs 7deg/day tank temperature loss: heat loss is a percentage of the temperature differential, so actual degrees drop per day depends on actual conditions.

A relatively short lifespan might be OK: many people would be quite delighted with a 10-year system lifespan. I'm sure many expensive complex systems don't last that long, due to some essential component quitting or new owners not wanting the burden of maintenance.

The doubled pipe insulation is quite clever: I'll definitely have to borrow that idea.

How do you meter the 120V electrical power? Kill-a-watt?

Nice data collection and presentation. Very helpful!

Affordable Solar Thermal

This style solar system has kicked around for a number of years. It comes up every so often when someone tries it and it gets hot water into a tank. It does hold some appeal for those non-freezing areas of the country. NREL, after years of working on systems that worked in the whole country, eventually set its sights on non-freezing climates since it is low hanging fruit and is pretty hard to mess up.

We had done work for NREL to develop all polymer low cost solar thermal systems for freezing climates.

At some point, I realized that for all the appeal that polymers hold in collector construction, copper and aluminum are not that expensive. And they do last. Polymer glazings and tanks make great sense in drawing cost down and perhaps good design can help with the rest.

We put together a DIY solar hot water system that is for freezing climates. It is DIY and the solar loop is all copper and requires no soldering. I don't want to make this an advertisement, and do not wish to demean anyone's efforts in doing an affordable system. I find that all my proteges in this neck of the woods like doing PVs because they just work. No cavitating pumps and no major maintenance.

I also am a bit chagrined at the solar folks I see selling tax credits more than affordable systems.

Maybe I am just getting old and grumpy. Maybe not..

Tom Gocze

American Solartechnics

Searsport, ME

Response to Tom Gocze

Tom,

It's OK to be old and grumpy.

It's certainly true that PV systems "just work," and have far fewer maintenance issues than solar thermal systems. And PV systems keep dropping in price.

I'm not familiar with your solar thermal systems, but I suspect there will always be a subset of homeowners who want a solar hot water system, and there will always be a few manufacturers to sell them equipment. These systems may not make much economic sense -- they may come with maintenance headaches and some pieces of equipment may experience premature failure -- but the systems are fun, and they can help reduce a homeowner's carbon footprint.

Batch heaters...

...with evacuated tube collectors can work. It's the go-to solution for tens (hundreds?) of millions of people in India & China, (even the colder parts of China), and elsewhere. Some versions even have resistance electric back-up to guarantee a minimum storage temp, and cover for cloudy weeks.

http://s88108.gridserver.com/wp-content/uploads/2009/04/solarheaters2.jpg

In US climate zone 5 it's probably do-able with just fat insulation on the plumbing to/from the batch heater. In US zone 6 & cooler it might require making the connection plumbing more freeze tolerant.

One example (among many) that is currently being inported into the US:

http://thesunbank.com/wp-content/uploads/2015/01/Sunbank-80G-Spec-Sheet.pdf

http://thesunbank.com/wp-content/uploads/2015/01/Sunbank_Manual_p1-9.pdf

If you can read Chinese and know what you're looking for you can probably get something decent online for under $1000, importing it grey market, quantity 1, but you may have to fight code officials to hook it up. In China a basic lesser insulated unit with no pressure rating without electric backup runs ~ $200 USD, to maybe 2x that for the deluxe better insulated version with an electric heater element and some safety & pressure ratings, eg:

http://imposol.en.made-in-china.com/product/avexONkUEchI/China-Quality-Assured-Unpressurized-China-Manufacture-Solar-Hot-Water-Heater.html

http://jialefu.en.made-in-china.com/product/NoEnYgMdCKRc/China-Pressure-Pressurized-Solar-Water-Heater-Solar-Geyser-Heat-pipe-solar-collector-.html

Anything that needs pumps smarter controls, freeze protection, etc ends up becoming the familiar, more expensive / less reliable Rube Goldberg contraptions we tend to think of. But a big batch water heater could cover the whole water heating load for at least half the US population if the home owners association won't freak out at the aesthetics of a tank on the roof.

Most 'merican families of 4 would want something like 300 liters (~80 gallons) of storage capacity in a batch heater it it's going to be the primary water heater, and the loading capacity of the roof needs to be verified for that much weight. You'd be looking at between 1000-1500 lbs of water heater + water, which may require some structural reinforcement.

Response to Dana Dorsett

Dana,

Batch heaters can work well in warmer climates, but it's important that we don't fall into the familiar trap of coming up with fake prices to make solar thermal systems seem more affordable (and more cost-effective) than they really are.

If you want to buy a batch heater with evacuated tubes and an 80-gallon tank, go right ahead. You can buy one for $2,800 from Sunbank Solar.

Needless to say, installation labor and roof reinforcement are not included.

Polyethylene/HDPE at up to

Polyethylene/HDPE at up to 170F at what pressure? Either I'm missing something or this won't last long. PEX should be OK.

I'd expect Dec/Jan to be about 25% of the summer output.

Competitive markets make a difference

The Sunbank solution I had already pointed to in the links in response #6, but sold in quantity into a competitive market (such as the Chinese or Indian domestic markets) the costs are quite low. The manufacturers' quantity-1 pricing of similar units on Chinese websites are not made up, but they haven't paid for SRCC certifications (though many are UL & CE marked) , since they're not selling into that market. The real street-price retail for a 150-200 liter batch heater in China really is only a couple hundred USD for a "pretty good" basic unit.

In a competitive first-world market there is good reason to believe that a Sunbank-equivalent with electric backup could be sold in the US for ~1/3 what they are charging, but at Sunbank's likely US sales volumes they would not even come close to breaking even at that price point. Units remarkably similar to the Sunbank in every respect (except for the SRCC certification) can be had in China for $350-$400, quantity 1, retail. In volume the piece price drops to the $200 range, $250 tops, and even with shipping a volume reseller in the US could still make money at $800-900. In a volume market the installation cost would come down too, and would likely come in somewhere in the $2K-3K range (highly variable with local labor markets.) That's roughly the unsubsidized installed price of a Stiebel Eltron Accelera 300 (or maybe even a bit cheaper), without the solar array needed to drive it.

Call this armchair analysis pricing "fake prices" if you like, but there are existence proofs of other products in that price range being resold in the US at comparable or lower mark ups. But there is currently no market to speak of here, ergo boutique pricing for a boutique market. But just because it could be financially viable, I don't expect to see it happen (ever) . The aesthetic issues alone would drive many people away, and the more familiar alternatives are still cheap enough to be affordable to the average 'merican. As PV efficiency grows concurrently with falling PV prices, heating water with a dumb standard electric hot water heater with grid-tied solar will eventually beat it on price/performance, and lifecycle cost.

Response to Dana Dorsett

As Tim Merrigan (from NREL) said, "The installed price [of a Fafco solar water heater] with labor is closer to $3,000. At that price, it’s still hard to compete against natural gas. The cost has to come down still lower to compete with natural gas."

Answering questions

I'll try and answer the questions I see in the comments. To start with Dana's question, legionella is a complicated question in the best case. We still seem to be trying to figure out how to deal with it. Variables, like a person's immune system health, make it hard to know just what is appropriate for a given situation... and then things change. I just listened to an expert plumbing designer give a talk on legionnaire's and what he said directly conflicts with a legionella expert's experience. Who do we believe? To try and answer the question of risk for this system, I'll be collecting a sample from the bottom of the tank and having it tested for legionella. I'll let you know what the results are. I can say though that energizing the upper element and setting it to a temperature that will control legionella growth could be a simple solution, although it would have an energy cost.

To Martin's questions: In the article, I put the cost at about $4000. Getting receipts from Zak, it actually adds up to $4369. I did not add in anything for labor or profit. We worked together so Zak's time is roughly half of the total time spent. Zak is a friend and this is clearly an experimental system, so I would have felt funny charging money to be experimenting on him. Given that, I didn't put in a number for labor. As to the plumber and electrician question, there wouldn't be much for an electrician to do. The control came pre-wired, so the only "electrical" was connecting the Marathon tank.

System design really depends on one's goals. One of Zak's goals was to design a system that could readily be converted to off-grid if desired. We installed more collectors than this system would otherwise have had in order to bump up the solar fraction. So, one possible cost savings would be to use three instead of four coils. This would probably not cost much in terms of lost solar fraction and would save at least $500.

To Tim Merrigan's comments; these collectors have an acrylic glazing and have been under test for 16 years so far without any glazing failure. A better and more expensive glazing would be UV inhibited polycarbonate, which would stand up to hail and other abuse much better. In our area, we don't get large hail, but certainly, every area has its own climate challenges to design for. I have to disagree with Tim about this system being only a DIY sort of thing, rather than something a contractor can install. Although one could make their own collectors, we used factory parts and I am a contractor, so I don't understand why "It’s not like a contractor-installed system."

To answer Skip Harris, we did use a Kill-A-Watt to monitor the system's energy use. And thanks for your comment on climate. I feel we need systems appropriate for a given climate, not one system that can handle everything.

Regarding Dana's batch heater idea; they would make wonderful sense if they didn't lose so much of their heat overnight. Steve Baer of Zomeworks came up with a nifty automatic insulating cover for batch heaters, but it was never produced commercially.

To John R., the water pressure from a gravity tank is 35 psi in this system. The collectors I mention in the article that have been under test for 16 years regularly see 160 degrees. The SDR-9 poly tube is rated for 200 psi at 73 degrees. I'd love to use PEX here if it could take the UV, but I don't think it can. Maybe some day, we'll have PEX with sufficient carbon black in it to prevent UV degradation. I know we're right at the pressure/temperature limits of the material, so time will tell. If the system does fall apart, I'll let you all know the error of my ways. Solar contribution in winter is certainly less than in summer, but because of the large storage, the system can coast through multiple sunless days. The system really does meet the hot water need 95% of the time.

Addressing some of Dana's comments, if we did less to make solar cost more here, no doubt we could drastically cut prices. I remember a presentation given at an ACEEE Hot Water Forum discussing the cost in China of solar systems and it was seeming crazy low at around US $200. The same system in the US was thousands. We add things like permit fees, insurance, import costs, shipping, and multiple markups that the Chinese don't necessarily have. I don't think we'll ever go so low, but it's worth looking at where soft costs can be reduced.

The goal here was to build a simple and durable system. I'd love to be able to tell you in thirty years that it's still perking along!

Yours, Larry

Response to Larry Weingarten

Larry,

Thanks for your very detailed, knowledgeable response. It is much appreciated.

I'm not going to try to speak for Tim Merrigan, who noted that this "system with plastic pipe falls into the DIY category. It’s not like a contractor-installed system." I'm not sure why he said that. But I'll note one fact: Since the reported cost of the system ($4,369 for parts) does not include pre-construction site visits, labor, insurance, profit, or a contingency for callbacks, the accounting side of your report amounts to a DIY approach, not a contractor's approach. I'd like to hear from a contractor who successfully (and profitably) installed 10 systems like this, so that the contractor could report the price point that makes these jobs profitable to a contractor.

Solar thermal system parts costs

Larry,

One more point: your cost for parts ($4,369) isn't much different than the cost for a two-collector system using collectors made of copper, glass, and aluminum. I'm pretty sure that the parts for my solar thermal system (which included two 4'x8' collectors made of copper, glass, and aluminum, a stainless-steel insulated storage tank, an El Sid pump, and a small PV module) cost less than $4,369.

Log in or create an account to post a comment.

Sign up Log in