Last year I wrote some articles on duct design and one of the topics I covered was this thing called friction rate. At the end of that article, I discussed “How to think about friction rate.”

It confuses a lot of people because it’s the wrong name. First I’ll tell you why and then I’ll tell you what I think we should be calling it.

Three important terms for duct system designers

At the beginning of my duct design series, I discussed the three big quantities that go into determining the sizing of ducts:

- Available static pressure (ASP)

- Total effective length (TEL)

- Friction rate (FR)

The available static pressure is how much push is left to move the air through the ducts after subtracting off the pressure drops for all the non-duct components in the system (i.e., filter, registers, grilles, etc.).

The total effective length is a way of characterizing how much pressure drop you’re going to have in the duct system. And the word “total” there means the total effective length of the longest duct run. In the duct plan shown at the top of this article, the longest run is shown in bold.

Calculating friction rate

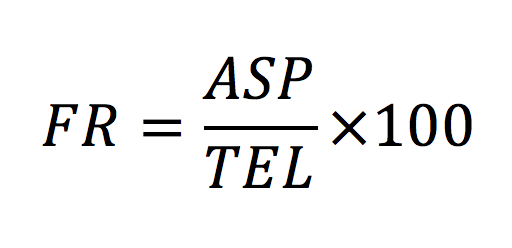

The friction rate is calculated from the previous two quantities:

The factor of 100 included in the equation is there to reduce the number of zeroes in the result.

The higher the friction rate, the better

Now, friction rate is based on available static pressure. It’s a number that tells you how much pressure drop you’re allowed to use per 100 feet of effective length in the duct system.

It’s a number that you want to be higher, not lower. And that’s why friction rate is the wrong name. Friction is generally something you want to minimize.

If I see a friction rate of 0.11 inches of water column (i.w.c) of pressure drop per 100 feet when I’m designing a duct system, I know the installers have some wiggle room. If they add a fitting or use a bad fitting or don’t pull the flex duct tight, the duct system will almost certainly still move enough air.

But If I see that the ducts are at 0.06 i.w.c. per 100 feet, there’s no wiggle room. One bad fitting could result in comfort problems.

Higher is better when it comes to friction rate. And that leads to cognitive dissonance because we don’t want a lot of friction in our ducts.

How about “available static pressure rate”?

If we called it “Available Static Pressure Rate,” it would be clear that higher numbers are better. So that’s my proposal. Let’s use that term instead of “friction rate.” (I’d actually prefer the term “Available Pressure Drop Rate,” but since we’re already using “Available Static Pressure,” it’s probably best to stick with that to make the connection clear.)

Allison Bailes of Decatur, Georgia, is a speaker, writer, building science consultant, and the author of the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

0 Comments

Log in or create an account to post a comment.

Sign up Log in