Image Credit: Mike Trolle

Image Credit: Mike Trolle Air sealing and insulation details developed with the Passive House Planning Package were critical to meeting the building standard and winning certification.

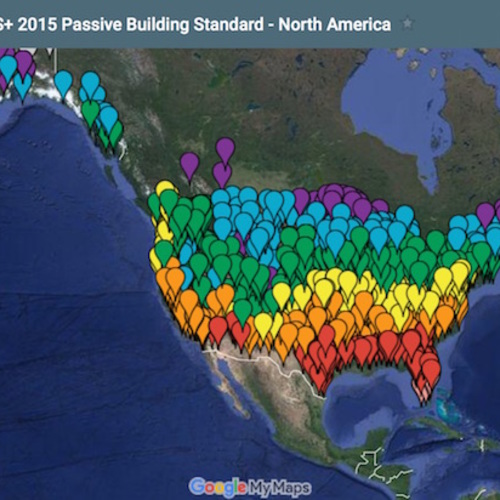

This is the first entry in what will be a series of columns about the design and construction of my own Passive House. This is a rigorous process, and although the house is finished, certification (through the Passive House Institute U.S.) is not yet assured. I hope to provide an inside and personal look at the various economic, design, building, and decision-making processes involved. I also hope to give you a better understanding of some of the Passive House building practices.

I believe that the Passive House program is a leading force behind the rapid increase in both technical sophistication and public momentum for energy-efficient housing. As such, I want to participate not just as a builder but as a homeowner.

The soon-to-be-rebuilt summer cottage

The main obstacle for me has been the cost to build a new home in a market where both land and existing homes are expensive. Existing homes are valued more highly than I think they should be, given their very poor energy efficiency. This made it difficult to find an affordable building site.

In the summer of 2012, I found a summer cottage in a Danbury, Connecticut, lake community (Lake Waubeeka). I was able to buy it for $135,000, far less than other options I’ve considered over the years. The cottage had a concrete block foundation that sits partially on ledge as the site rises to the rear. A room behind the house was built on concrete block piers. Given my performance goals for the house, it made little sense to keep anything other than the foundation and the first floor deck framing.

I sold my Ridgefield house in February of 2012 and began work on the design of a new house with Passive House certification (PHIUS) as the target.

My design tool

I decided to design the house myself using Softplan design software. It’s an architectural program that my company owned but that I had never used. With the assistance of Softplan trainers, I used the design process as a vehicle for learning to use the software. It was a useful and rewarding experience for me as a builder. However, I’m not sure that I would recommend it for everyone. My years as a builder working with architects were a big help. I think it would be much harder for someone without that background.

Despite our 12 years of experience building award-winning green homes, my brother Chris and I decided to take the nine-day training program required to become Passive House consultants. This was a good thing because the technical sophistication of the program is a big step up from what had been available previously.

Chris has since passed an exam and become a PHIUS consultant, which means that he can work with architects and homeowners to develop plans for homes that could be PHIUS certified. With this background, I was able to begin work on the design.

The Passive House certification program requires the use of a detailed multi-worksheet spreadsheet program to create a detailed analysis of the heating and cooling requirements for a house in order to design the thermal envelope and to specify appropriate heating, cooling, and ventilation equipment.

The “thermal envelope” is the enclosure that separates the interior conditioned environment from the outside ambient conditions. Typically, this is the foundation, framed exterior walls, and the framed roof or attic floor of your home. Whether it’s the foundation, walls, or roof, the thermal envelope includes the framing, insulation, interior finish, and exterior finish. This is the single most critical element of an energy-efficient home.

The new house would have a simple rectangular shape with a gable roof, a large shed-roofed dormer, and a small side addition. I developed the details of the thermal envelope based on my years of experience building high performance homes, my Passive House training, ideas from other Passive House projects, and the specific requirements and limitations of my site and design.

Working with PHPP

The PHPP (Passive House Planning Package — a 36-worksheet spreadsheet program for analyzing energy requirements) forces you to think about the house design, the thermal envelope, and the heating/cooling equipment in minute detail. Dimensions and specifications are used to calculate BTUs of energy required to operate the house, which has to meet strict standards for certification.

As you enter data, you are rewarded with immediate feedback telling you whether you have helped or hurt the home’s performance. Every entry serves to guide your selection of materials and assemblies to meet the Passive House performance goals.

A Passive House must be close to airtight, as air leakage is a big source of heat loss in homes. The detailed section drawing (see Image #2, below) shows the location and materials used to create the continuous air seal. Airtightness is measured by a blower door test. In order to meet the Passivhaus certification standard, there must be no more than 0.6 ach50 (air changes per hour at a 50 pascal air pressure difference between inside and outside the house). The current code requirement in Connecticut is 7.0 ach50, nearly 12 times the Passivhaus standard).

Planning must be rigorous and execution perfect. A single mistake is likely to prevent certification. Here, my primary strategy for air-sealing is plywood sheathing with taped joints. Note how continuity is maintained from floor to wall to roof.

High levels of insulation

Achieving high levels of insulation is mandatory. Eliminating thermal bridges is another critical goal. Thermal bridges are structural elements that are continuous from interior to exterior and have a very low resistance to heat transfer. Concrete and steel are the worst, but wood framing is a problem, too, as it also loses heat more quickly than insulation. Note how these potential problems are resolved by the careful detailing of foundation-to-wall and wall-to-roof intersections.

If you would like to see floor plans and elevations, you can visit my blog at the BPC Green Builders website. The elevations show the calculations for the thermal envelope dimensions required by PHIUS. Wall and roof planes overlap in order to deal with the higher heat flows at intersecting planes.

Here’s a link to Part 2 of this blog series: Tearing Down to Start Again.

Michael Trolle is a co-founder of BPC Green Builders, in Wilton, Conn. This post, and the ones to follow, were originally published in slightly different versions at The HomeMonthly.com but also are available at the BPC Green Builders website.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

4 Comments

Michael

A really interesting project with the added complexity of working with the exiting foundation and floor. i don't want to jump the gun if you intend to deal with this in future blogs, but how did you deal with the potential for settlement of the new slab on that much EPS when it appears to be part of a floor that extends into the existing house?

Settlement question

The slab and the existing foundation are adjacent but not connected. Same is true with the finished flooring. The slab sits on the 12" of EPS over 6" of crushed stone over undisturbed soil. 2-1/2 years after the slab was poured, there is no indication of settlement, and the 12x24 tile over the slab is perfect. The slab edges do have a thickened and reinforced edge. I will ask GBA to post a picture.

Roof insulation

Curious how you decided to use an unvented, cellulose insulated roof?

.

Roof insulation question

I assume you are questioning the assembly in light of reports of condensation problems in other somewhat similar assemblies. I went this route after consulting with the technical manager at National Fiber who had been testing similar assemblies in New England for the last several years. His findings have been that this works as long as the assembly is air-tight and the rafter cavities are filled completely with cellulose so that there are no voids. We have been monitoring moisture levels in the assembly since completion. After the first winter, the moisture content (MC) of the interior face of the exterior plywood sheathing was 11% on my south-facing roof and 7.5% on my west-facing roof. This spring, after an unusually cold winter, the numbers were 8.3% and 7.8%. So there's been no problem. My interior RH during the winter months starts out around 40% and drops into the low 30% range by the end of winter. I think that the moisture storage potential of cellulose is helpful, and I have 18" of it. I think that using plywood as the interior air barrier and vapor retarder also helps to manage vapor flows.

Log in or create an account to post a comment.

Sign up Log in