The insulation choices we make can significantly impact the amount of embodied carbon that is in our construction projects. Last year, I set about determining how much of an impact different materials have. I also wanted to find a way to make the materials selection process easier for others.

The lifecycle “cost” of carbon involved in building construction can be measured by the global warming potential (GWP) associated with the manufacturing and use of each building component. This is measured in carbon dioxide equivalence (CO2e).

My focus was specifically on insulation, which is a product that customers and contractors generally choose based on cost, durability, availability, and building science. A material’s GWP is not typically a decision driver.

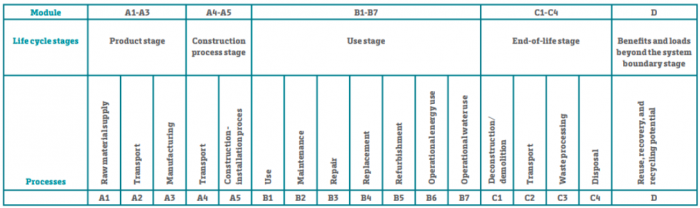

Since there wasn’t a broadly accepted way to both easily and scientifically measure carbon for insulation materials, I began by looking at Environmental Product Declarations (EPDs). These detailed reports are published by manufacturers and trade organizations, and provide loads of data on “life cycle costs.” See Figure 1 for an overview of how that data gets broken up.

Life cycle stages as defined in the European standard EN 15978

I looked at insulation products that cover a lot of square footage in the construction or renovation of foundations, above-grade walls, and ceilings. From there, I made a list of available products ranging from blueboard to fiberglass to wood-fiber insulation, and then compiled every available EPD—the list included close to 200 materials. Priority was given to non-expired EPDs (they have a 5-year shelf life) for products manufactured in North America, but European-manufactured materials were acceptable if no North American products existed or the source was exclusively European.

Most EPDs report GWP based on one square meter of the thickness of material needed to reach RSI-1, which is R-5.678 in imperial units. If…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

7 Comments

Nice work, very informative. As an owner/ builder my greatest concern is wildfire in Colorado. According to the Insurance Information Institute in 2020 there was 58,950 wildfires that burned about 10.1 million acres. Total loss estimates of structures were estimated at 17,904. It is estimated that there are more fires in the eastern states, but they are typically smaller. I don't see any choice other than mineral wool as a viable option for exterior insulation. The GWP of replacement cost is overwhelming.

Thanks for this great work in collecting this information and making it useful.

I think that using this to avoid the high positive impact materials is really important--essential if you want to call your project green building.

I also think that a negative number is a good thing, but I think more caution is warranted in using those numbers for decision making. Using a wood product does sequester carbon, but so does leaving a forest intact and letting the trees grow bigger. Figuring out what the appropriate analysis is much more difficult and fuzzy for these types of materials. Those materials are still clearly the best bets, but I would want to count on those negative numbers offsetting other impacts, such as long daily commutes to the job site, for example.

“[Deleted]”

$100 to save 52 tons of CO2e is great. $2000 is marginal, might do better by donating the savings to the right cause.

> just 3 in. provided R-24,

You should ignore the short term marketing number and use average R value over the life of the insulation. And for typical exterior use, further adjusted downward for poor cold weather performance. So almost certainly less than R17.

I am just reading through a lot of threads while deciding on what exterior insulation to put on my home. What a rabbit hole! Jon, I have been looking at the Kooltherm product and am interested in your comment about < R-17. Where does your <17 estimate come from? I haven't found much phenolic foam data online thus far. Thanks!

Great article, however the link in the Health Intersection section to the GreenBuilding Guide for some reason takes me to an apple laptop website.

Thanks Brian and GBA team!

Here's a link to the purchase page to buy the 4th edition, one edition newer than what was mentioned here.

https://www.buildinggreen.com/continuing-education/buildinggreen-guide-thermal-insulation

Log in or become a member to post a comment.

Sign up Log in