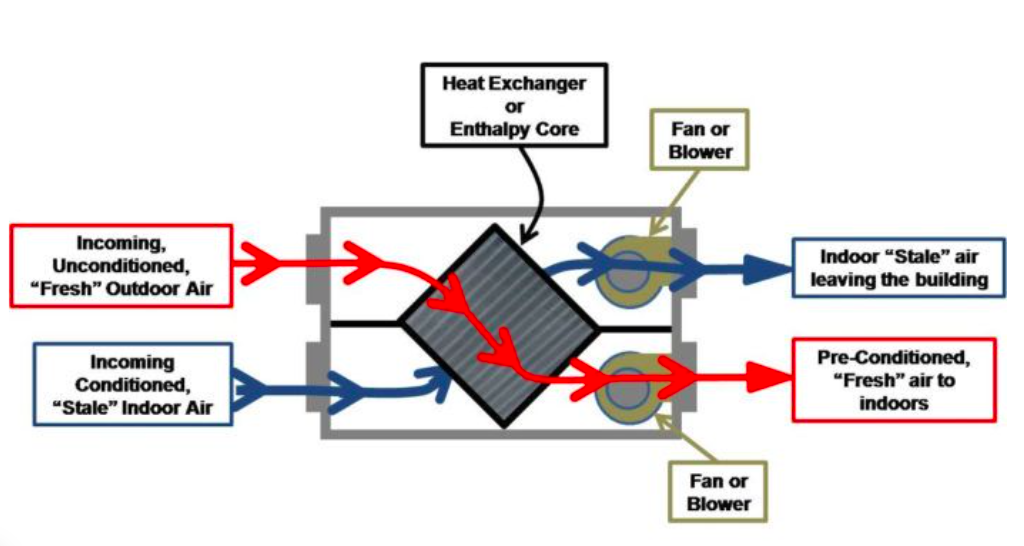

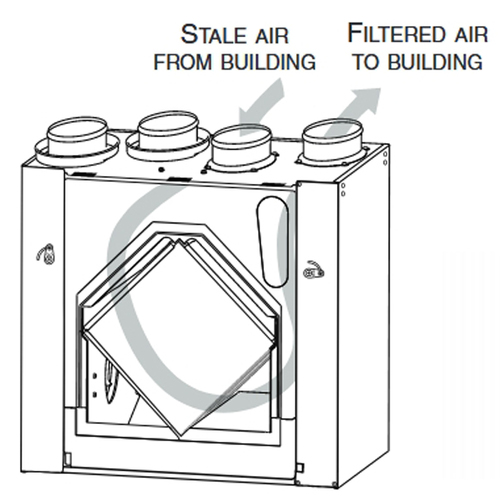

Here at GBA, we have consistently advised readers who plan to install a heat-recovery ventilator (HRV) or an energy-recovery ventilator (ERV) to install dedicated ventilation ductwork rather than trying to distribute ventilation air through their heating and cooling ducts. That advice won’t seem particularly burdensome if your house doesn’t have any heating and cooling ducts — as is typical in a home with ductless minisplits or a hydronic heating system and no central air conditioning.

But if your house already has heating and cooling ducts, you may instinctively rebel at GBA’s advice, muttering, “Why can’t I use the ducts that I’ve already got?”

Here are the reasons:

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

36 Comments

I'm hoping that Bruce Sullivan who wrote about this ("Six Steps to Success with Heat-Recovery Ventilation," January 2018) will comment, reflecting Bruce Manclark and Dan Wildenhaus.

Duane,

Bruce Manclark and Dan Wildenhaus provide recommendations for distributing ventilation air through heating and cooling ducts in an article by Bruce Sullivan called "Integrating HRVs With Air Handlers."

The approach they describe is less bad than most attempts to use heating and cooling ducts to distribute ventilation air -- but still complicated enough to raise questions about whether it's possible to find an HVAC contractor sophisticated enough to follow the steps recommended by Manclark and Wildenhaus.

In Bruce Sullivan's first article in the series ("Six Steps to Success With Heat-Recovery Ventilation"), he recommended, "Create a dedicated duct system. Most experts agree that it’s best for an HRV to have its own dedicated duct system."

That's advice worth listening to.

Thanks Martin, excellent article as always. I'd like to second the emphasis on dedicated ductwork for an ERV installation. We encountered a new, light commercial building in VA that experienced high moisture problems when the ERV was activated, much of it due to poor ducting that was indeed tied into the main HVAC ductwork. Even the manufacturer stated the AHU needed to run during ERV operation but that's not how it was configured.

In my personal home, I took care to hard duct my ERV as much as possible, even splitting the fresh air being supplied to the house into two rooms as well as pulling stale air from two places. This six duct arrangement led to airflows that were significantly higher than the 70 cfm that the ERV is rated to provide! I have come to the conclusion that, at least in my neck of the woods, it's preferable to let the bath fans and kitchen hoods handle the moisture loads in those locations. I give Terry Brennan credit for suggesting pulling ERV "stale" air from the closets.

I'm concluding that my dream ventilation system in a mixed-humid climate like Atlanta and the southeast is an ERV with supplemental dehumidification . The other feature I'd like to see is the above system with temperature/moisture sensor controls to reduce/shut off the ventilation system and coast when the outdoor conditions are "bad".

Again, thanks for your excellent contributions! -mike barcik

Mike,

You wrote, "I'm concluding that my dream ventilation system in a mixed-humid climate like Atlanta and the southeast is an ERV with supplemental dehumidification."

You should check out the CERV and the Minotair. Here are links to articles with more information:

"A Balanced Ventilation System With a Built-In Heat Pump"

"Another North American Magic Box"

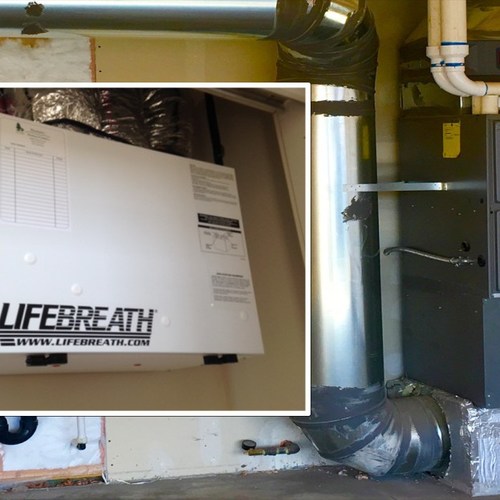

What about products like a Clean Air Furnace?

https://www.lifebreath.com/us/product/clean-air-furnace-6/

They can be spec'd with ECM's and are inherently "interlocked" since they use the same blower motor.

Crontab,

I don't know much about Lifebreath's Clean Air Furnace, but I'm interested in reports from GBA readers who have installed the appliance.

I'm not impressed with the documentation provided by Lifebreath for this appliance.

First of all, the so-called "Clean Air Furnace" is not a furnace. It's an air handler with a hydronic heat-exchange coil. Unlike a real furnace, the "Clean Air Furnace" does not produce heat. To produce heat, you need to buy a boiler (or, in some but not all jurisdictions, a water heater) and connect it to the "Clean Air Furnace."

That fact alone should raise questions with government regulatory authorities. It shouldn't be legal to advertise a product that is not a furnace by calling it a furnace. That borders on fraud.

For more information on hydro-air systems and the type of air handler that Lifebreath is mis-labeling, see "Using a Tankless Water Heater for Space Heat."

The instructions note, "The heat recovery ventilation (HRV) portion of the Clean Air Furnace, is automatic. Once set, a desired amount of fresh air will be drawn into the home while the furnace blower is activated." A designer needs more information. A designer needs to know a few basic facts about this air handler, including:

1. Under what circumstances is exterior ventilation air introduced into the forced-air heating ducts? Is the ventilation air introduced only when there is a call for heat, or is the ventilation air introduced year round?

2. If this appliance can operate in ventilation-only mode, without any space heating, how many watts does it draw?

Hi Martin.

Thanks as always for your deep dive into this topic. Perhaps some mention could have been made about home-run ducted systems with smaller, flexible ductwork that can fit within stud walls and floor joist cavities without elbows, boots or other increases to static pressure. You might also mention challenges with sound attenuation (and additional air sealing) with metal elbows and boots, as well as the potential for "cross-talk" between rooms with trunk and branch duct systems.

Also, your several references to "a call for ventilation" or "no need for ventilation" seems to imply that ventilation is only intermittent. I think it's worth noting that, particularly in brand new construction, continuous ventilation (with very low Watts/cfm, of course) may provide benefits that intermittent ventilation may not. And wouldn't it be nice to know that if a damp bath towel is left on a towel bar, continuous ventilation will likely remove that moisture more effectively, and with smaller, less intrusive ducts?

John Rockwell

Zehnder America

http://www.zehnderamerica.com/

John,

It's possible to meet ASHRAE 62.2 ventilation requirements with continuous ventilation, as you point out. It's also possible to meet ASHRAE 62.2 ventilation requirements with intermittent ventilation.

For example, if your house needs 60 cfm of continuous ventilation (according to ASHRAE 62.2), it's perfectly acceptable to ventilate at 120 cfm for 30 minutes every hour. I haven't seen any evidence or data that the latter approach is inferior to the former approach.

Moreover, many homeowners program their ventilation systems so that ventilation is minimized or off when the occupants are at work or school, in order to reduce the inevitable energy penalty associated with ventilation.

Having the HRV go to low or off when away is a separate issue from intermittent ventilation. There are two obvious downsides to intermittent mode ventilation. All other factors being equal, 120cfm is going to be a lot louder than 60cfm (likely more than double). How much, or if at all, this bothers the occupants will vary. Running 120cfm at 50% duty cycle will also use more energy than running 60cfm at 100%, due to the nonlinear increase in power required as static pressure increases. This may be negligible, I haven't done the math. A third possible factor is that is to run at those higher cfm rates on an intermittent basis may require upsized equipmemt.

Thanks for the article. I installed a Panasonic ERV in the attic of my 1930s colonial (CZ4a) this year in a hybrid configuration. I agree that there are some compromises, though a fully ducted system would have added significant expense and its own trade-offs.

On the plus side, I get air mixing and filtration via the MERV 16 filter in the air handler in the attic, which is for cooling only. Since I have a boiler for heat, I think that's a benefit in the heating season. The AHU is new and has a very low fan speed (configurable, ~425 cfm). At less than 30 W, it's not a significant energy concern. I would not have considered a blower interlock with a PSC motor. The fan speed is low enough that my wife and kids haven't been complained of cold air blowing. That was my biggest worry since I installed it over the summer.

Balancing is a real concern with a hybrid or simplified system. My AHU operates at three fan speeds (Max dehum/Fan ON [50%], dehum [80%], cooling [100%]). It was easiest to balance my ERV at the highest fan speed. Of course, that's the mode it's in the least while the ERV is running!

Panasonic says that an AHU interlock is required, interestingly. I have a central return, so distribution without the blower would be really poor. I'd be curious to try without interlocking if I had a different duct layout.

The controls side is a work in progress and not entirely satisfactory. An Ecobee controls the A/C, including a "dehumidifier" which is just a reduced fan speed on the AHU. The Ecobee is smart enough to minimize fan on time when the compressor is not running to avoid evaporating condensate on the coils. But, the Ecobee doesn't know anything about the ERV. So, I ran the ERV for 40 min/hr at 60 cfm to get an average 62.2-specified 40 cfm. (I was having trouble getting it balanced at higher fan speeds, but that's a long story.) Now in the heating season I'm running it full-time at 50 cfm (lowest setting) and watching CO2 levels to try to determine a temp cutoff where stack effect is providing enough ventilation. I may try to use the Ecobee to control the ERV in the heating season to see how that works.

Panasonic, are you listening? I'd love to see an ERV controller that would use weather conditions and a CO2 sensor to help determine ventilation rates. And ideally talk to an Ecobee/Nest/etc via their respective APIs. So far I've resisted the urge to see if I can control the ventilation rate, having previously created a proof of concept Wi-Fi variable speed controller for a Panasonic FV-05 bath fan. (The fan speed is proportional to a 0-5 V control signal.) Anyway...

Bottom line, I think the hybrid configuration can be a good option for existing houses with ECM blowers and some due diligence about the potential trade-offs (and benefits). I think I'm way ahead of an exhaust-only scheme despite it not being an "ideal" installation. Certainly a lot better from a humidity-management perspective, which always seems like a challenge.

Jeremy,

Your design instincts and commissioning skills are well above average. I commend you for your diligence and analytical approach.

That said, even someone with your skills has concluded that, "Balancing is a real concern with a hybrid or simplified system. My AHU operates at three fan speeds (Max dehum/Fan ON [50%], dehum [80%], cooling [100%]). It was easiest to balance my ERV at the highest fan speed. Of course, that's the mode it's in the least while the ERV is running!"

You also note, "An Ecobee controls the A/C... The Ecobee is smart enough to minimize fan on time when the compressor is not running to avoid evaporating condensate on the coils. But, the Ecobee doesn't know anything about the ERV."

It's important to imagine the likely results if a system like yours were commissioned by either (a) a typical HVAC contractor, or (b) a typical homeowner. The results would probably be highly unsatisfactory, and resulting air flow rates would be all over the map.

Good points, Martin. I find it frustrating that there are seemingly a lot of barriers to getting H/ERVs into more homes — installed to be effective — given that there's a lot of good they can do for IAQ while minimizing the energy penalty.

Here here to the comment above. I too have radiant heat and would like AC and fresh air. But the penalty to floor and ceiling space is very large. Very difficult to make/find a system for this.

I would like to qualify my following statements with the fact that over the last couple years I’ve commissioned dozens of residential ERVs, most of them (unfortunately) in the simplified configuration. I’ll also vent my frustration that all of the HVAC contractors I work with do not really understand the relationship between these ERVs and the space conditioning ducts they’re connecting them to, even more frustrating is that most of them don’t seem to care. There is good reason for hope though, because with commissioning it is entirely possible to get any one of the configurations working well.

I’d like to defend the hybrid configuration as a good way to reduce overall duct work and advocate here for always connecting the fresh air from the ERV to the supply side of the air handler in both hybrid and simplified systems. Most manufacturers allow for this (see attached image) and there are several advantages to this.

First, it’s a best-case scenario for not running the air handler fan because the filtered fresh air distributes through the supply duct work when the air handler is not running. The lower air flow of the ventilator combined with the resistance from coil, heat exchanger and filter tend to prevent most back flow to the return side. My own testing shows this general holds up. The addition of a one-way damper or zone damper at the air handler could prevent back flow all together. I’m going to make myself a custom cape damper for my own setup and see how it performs (whenever I get the time).

Second, preventing unintentional flow through the ERV when it’s not running can be accomplished with a simple one-way damper instead of a powered damper.

Third, in a simplified configuration, where stale air is being pulled from the return duct and fresh air being pushed into the supply, the cycling of the air handler resists both ventilation streams (fairly equally assuming decent duct design) instead of resisting one and assisting the other. What this means is that the ventilator may flow less air overall but is still relatively well balanced.

Furthermore, in the installations I’m seeing, with flex duct runs to outside, the ERV fans are operating at significantly more TESP than the 0.1 to 0.2 iwc in the space conditioning duct work, 0.4 to 0.6 generally, which means the ventilation air flow doesn’t actually change all that much when the air handler turns on and off. In my own ducted mini-split setup the 0.06 iwc in the supply ductwork changes the HRV fresh air flow from 110cfm to 100cfm. Curiously, this is right at the 10cfm tolerance considered balanced from the manufacturer.

The point is, if you design and commission it, you can reduce duct work and avoid running the air handler fan for ventilation.

Some manufacturers recommend in their installation manual furnace interlock when running the AC to avoid condensation and mold in the duct. See the note on setup T-5 in this manual: https://www.broan-nutone.com/getmedia/26847653-1424-49e1-9415-6b2e8becf223/Installation_Guide_AI_2_Broan_En_1.pdf?ext=.pdf

Andy,

Thanks for sharing your experience and tips. You've come up with a superior way to distribute ventilation air through heating ducts, and I salute you.

However, the HVAC industry still faces a major challenge here, because (as you admit) very few HVAC contractors understand the principles you discuss well enough to commission an HRV as you recommend.

Designing the ventilation connection is always a balancing act. Obviously independent ducting is the absolute best way to achieve all the benefits from an ERV installation. However, retrofits can make this style of installation very difficult, mainly because routing branch ducts around an existing home can be nearly impossible. Especially if the customer has a budget.

In new construction; we (as a manufacturer) always recommend an independent system exhausting from bathrooms and supplying to living spaces.

In retrofits; we try our best to find a balanced approach that solves IAQ issues while also keeping installation costs as low as possible. Often this is done with hybrid systems. Exhausting from a central location (preferring Bathrooms and Kitchens) and supplying into the larger furnace ducting network. One option is to have the ERV tied to the furnace fan; while also having the furnace fan linked to a timer that triggers the fan 20 minutes out of each hour. This way the ERV distributes fresh air even during shoulder seasons when the furnace/AC might not be operating as often.

Also, zoned ERV installations have become more popular in retrofits. Rather than installing a single large ERV system and routing ducts throughout the residence -- people have chosen to install 2 smaller ERV units to minimize the length and complexity of ducting. For a two story home, one option is a small ERV in the basement and another small ERV in the attic. Running independently of each other and supplying balanced ventilation to the respective floors.

Thanks for the “zoned” idea for retrofit. I have a 130 year old 2-story with a partially finished basement and was really scratching my head as to how I could get 1 ERV to reach the upstairs beds and bath, and the main and basement spaces. Splitting it up would greatly simplify the ducting challenge.

In old barns around here (climate zone 7) with tons of insulation in the ceiling (hay) wooden ventilation chimneys would pull out stale air from the barn and it would be replaced with fresh cold air through the cracks in the walls, doors and windows. Could an HRV perched on the top of such a chimney perform a similar function using less energy and making less noise?

Martin,

I had written to you before about installing an ERV in my walk-in attic with drop-down ducting for exhaust and intake. You said I would be way better having the whole thing within the thermal envelope of my house. My basement is part 1/3 full-height and 2/3 crawl space open to the full-height section. The whole of the basement is kept on the cool side for the sake of precious liquids stored there. Would the crawl space be a good location for the ERV? Certainly the ducting would not have any great run. I could also have the exhaust split between the two bathrooms using the the wet wall between them, as well as running an exhaust from the kitchen. Your thoughts?

(The house is a 1 1/2 story, 2000 sf, located in the Philadelphia, PA area, natural gas forced air heating/cooling, with room dehumidifier in the basement and dehumidification for the rest of the house handled by the Lenox A/C running a low speed)

George,

In New England, HRVs or ERVs are usually located in a basement. As long as the basement is clean and relatively dry and the duct system is well sealed, a basement is an excellent location for this type of equipment. Crawl spaces work too, as long as the crawl space is conditioned, clean, and relatively dry. A crawl space with a dirt floor and open vents would not be a good location.

Let's consider two of your comments for the purpose of discussion of my recent, heretical thought: ERVs in most houses (including mine) are wasteful.

1) "In the past, I often endorsed the use of exhaust-only ventilation systems in small homes with simple floor plans. Increasingly, however, I’ve become convinced that we need to pay better attention to indoor air quality, especially in bedrooms."

2) "The exhaust air and supply air flows of HRVs and ERVs need to be balanced after they are installed. This balancing process is known as commissioning."

We have had 2 ERVs in our 4 level/2 HVAC system house for 8 years or so (we had a third HVAC system removed after making many energy improvements over the course of 20 years). The ERVs are connected to our HVAC cold air return ducts (our ducts are aerosealed). We run the HVAC fans on low 24/7 (ECMs use about 30 watts each) to filter the air (3 beautiful cats) and to equalize the temp/humidity throughout the living area.

The main purpose served by a ventilator (ERV or HRV) is bringing fresh air into the house. The exhaust-only ventilation approach used the house's "natural" leakage to bring fresh air into the house. We now recognize that a problem with that approach is that unconditioned/unfiltered air is brought into the living space. Enter the ventilator which partially conditions the air before inserting it into the living space. The ventilator then dumps the other portion of that partially conditioned air to the outside of the house as "exhaust".

The house ventilation process as currently practiced literally dumps energy out of the house because it intentionally exhausts air which was previously, and is still partially, conditioned and filtered. Moreover, installing an ERV does nothing about the "natural" house leakage, especially if the ventilator is balanced. Using a balanced ERV seems to bring two bad results: a controlled dumping of energy out of the house, while failing to address the unwanted infiltration of unconditioned/unfiltered air through "natural" leakage.

The ventilator "exhaust" air was previously filtered and conditioned by the HVAC system, in other words, money has been invested in that "exhaust" air. What if we treated that ventilator "exhaust" air, which we are currently dumping outside of the house, as being better and more valuable than the tainted outside air and returned it to the house instead? The ventilator would still bring in fresh air, but returning the "exhaust" air to the interior of the house would slightly increase the air pressure in the interior of the house and the interior air would be vented to the outside via the "natural" leakage of the house. Rather than intentionally dumping partially conditioned/filtered air to the outside, wasting all of that energy, we should reuse that expensive air which will tend to keep the untreated outside air where it belongs, outside the living space. If the ventilator "exhaust" air is returned to the house via the HVAC's cold air return, the air which enters the ventilator from the outside will be filtered four times per circuit! "Balancing" an ERV or HRV becomes a non-issue because the "problem," if there is one, will either be "too much" air taken from the outside or, if too much air is being taken from the HVAC or house, it is being returned to the HVAC or house and the net change is zero.

After 20 years of sealing our house, I think we still have about 2.5 ACH (the person who did the blower door test told me it was the tightest house he had ever tested, like me, he was not a young man), I think the required minimum is 0.35 ACH? We're about 7X above the minimum after years of concerted effort. The vast majority of houses are not air tight, we need to stop treating ventilation as if we lived in hermetically sealed boxes. Rather than ERVs or HRVs, all that is needed is a much cheaper "fresh air ventilator" which prefilters the air to remove leaves, sticks, bugs, and large particles. Let the ventilator ventilate and let the HVAC system do what it is designed to do, condition the air and apply a fine filter to the process. If winter moisture is a problem, then injecting dry winter air into the house should help more than employing an energy dumping ERV which will return moisture to the house because it is only partially efficient at moisture removal.

Tim,

You are proposing a supply-only ventilation system, and you are not the first person to propose it. Supply-only ventilation systems are the type of ventilation systems preferred by Joe Lstiburek, among others. The most common type of supply-only ventilation system is a central-fan-integrated supply ventilation system. For more information on central-fan-integrated supply ventilation systems, see "Designing a Good Ventilation System."

One other note: Your proposal depends on your forced-air heating system for filtration, which is fine. But many U.S. homes are heated hydronically, so they don't have a forced-air heating system. Hydronically heated houses still need ventilation.

Thanks! My stumbling experimentation led me to Joe Lstiburek? That's a pretty good arrival point! ;-) Thanks for the link, I'll check it out.

My comment about dumping the ventilator's exhaust air into the house was not meant to apply only to forced air systems. Thanks for the clarification. From what I have seen from owning three different brands of ERVs, their filtering systems are weak compared to HVAC filters (not talking about those spun fiber glass monstrosities, but MERV rated 1"-4" filters). But even with the comparatively weak filtering systems offered by ERVs, that filtering yields better air than the outside air, so it's still better to "exhaust" the return air back into the home.

(edited)

Martin, your link seems to be missing the URL. I believe it is supposed to be https://www.greenbuildingadvisor.com/article/designing-a-good-ventilation-system

That's it, thanks!

Thanks, Charlie. I just fixed my link.

To qualify myself: I am not an expert, I have a engineering background and I read the article/ thread very carefully. I am still not convinced that a separate ducting is the way to go especially for the filtration quality (my wife is allergic to dust). Does GBA still support this position in a new construction? The solution suggested by Andy Kosick seems very valid to me.

The CONS listed in the article are not very convincing to me or do not apply to Andy's solution:

1. Heating and cooling ducts are always larger...

-Larger ducts decrease pressure drops so it sounds more of a benefit than a cons to me.

2. Heating and cooling ducts are usually leaky...

-This also applies to separate ERV ducts plus extra ducts can cause extra problems and costs in installation and maintenance.

3. If the homeowner expects to use the furnace fan or air handler fan to distribute ventilation air, the energy use associated with ventilation increases markedly.

-This does not seems to apply to Andy's solution.

4. Using heating and cooling ducts for ventilation usually means that you can’t choose the rooms from which you exhaust stale air, nor can you choose the rooms to which you deliver fresh air.

- This is true but is this a deal breaker? Maybe a system like VentZone that extracts air only from the bathroom can mitigate the problem.

5. When ductwork is shared, the HVAC installer has to plan for several possible operational modes...

- If we use an always on HRV there are only 2 operational modes. Andy Kosick solution requests at most two one-way dampers.

Is there anything else I am not considering?

Cococchio

Thought I'd chime in as my thinking has evolved on this some what.

First, I'll hold up everything Martin said below. The root problem here is really that residential HVAC is a complete mess. Contractors do minimal design often incorrectly and commissioning is non existent. It's no wondering why ventilation systems aren't working. In that, I completely respect Martin's opinion that separate systems may be the best way to yield a decent result, especially for people not up to managing all the details themselves, but that does come at additional cost and in more ducts to find places for. The real solution here is to overhaul the HVAC industry, a monumental (if not impossible) task that I've found myself more a part of than I would have guessed a couple years ago.

Second, how my thinking has evolved in case it's helpful. If you are space conditioning with forced air, which I recommend, a continuously operating low fan is foundational to good performance of the home. It's worth every kWh and penny, which isn't much if it's designed right. This opinion is based on evidence from monitoring and living with it.

The advantages are:

1. Continuous filtration of the living space. (go MERV 13)

2. Mixing the air helps even out temperatures and humidity throughout the home.

3. Mixing the air helps make all the air inside the home available to any given room, reducing to need for fresh air overall.

Let explain the 3rd one. I currently have an HRV putting fresh air into the supply ducts for my ducted mini-split much as described above (cape damper and all). I ventilate at 50cfm (measured), which is about what ASHRAE 62.2 -2010 calls for the home. I have 6 registers, and that means 8-10 cfm of air enter my bedroom (measured) without the air handler (AH) fan running. Like this the CO2 measured by an IAQ sensor spikes well over 1000ppm at night when we are sleeping. With the AH fan running continuously there is always at least 40cfm of air blowing in the room. Ventilation plus mixing air from the rest of the house and it keeps the CO2 to about 600-800 range. Technical gibberish aside, you can feel the difference, I mean it. An independently ducted ERV is going to look more like the first situation, perhaps the outlets would have better throw and mixing, and you could increase the ERVs ventilation rate and just over ventilate the rest of the house but I'm finding the energy penalty of mixing is less for roughly equivalent air quality.

That energy penalty? See the picture from my monitor below. The HRV is drawing 20 watts to move 50cfm of air and the heat pump 1 and 2 (both legs of the breaker) is using about 40 watts, but it draws 10 watts on standby, so about 30 additional. That's about $4 per month, and if the variable speed heat pump is sized right, it's going to spend most of the time running anyway so the penalty is even less. Maybe $20 a year. A bigger system might be $40 or $60 per year.

Hope that helps. Remember thorough design up front, commissioning to make sure it's doing what it's suppose to.

(Good Grief, this almost feels like an article if you guys are interested, and I've actually got more than this to say of the subject. )

Thanks, Andy. All good points! I hope you contact GBA editor Kiley Jacques with your offer to write an article on this topic -- it would be a good read. Here's her email address: [email protected]

Martin and Andy thanks for your detailed answers. Folks like you make GBA a great place to learn quickly. Martin looking forward to your article! I guess the message here is that something that in theory could work well, in practice can become a nightmare if the installer does not really understand what he's doing . A similar concepts I believe applies to GSHP. So the key question is how we select a "qualified" HVAC guy? I am assuming that the ventilation and HVAC system has to be designed by an indipendent engineer. Maybe requesting the engineer to advice a local qualified contractor would be a wise idea?

Cococchio,

Actually, it was Andy, not me, who sounded like he was volunteering to write an article.

If you want to hire a qualified person to perform a Manual J calculation and to design your residential heating system, I recommend Allison Bailes of Energy Vanguard (https://www.energyvanguard.com/about/allison-bailes-iii-phd/). He's a reputable consultant and a GBA blogger.

Finding a good local HVAC contractor to follow Bailes's specs may be tricky. Good luck with that!

For a ventilation system, you can't go wrong if you buy a Zehnder HRV and let their factory-trained rep install it. That's a foolproof approach, but it won't be cheap.

Cococchio,

Thanks for your comment.

My article's recommendations are based on the fact that researchers have found that residential ventilation systems, as installed, are a mess. Most don't provide the ventilation rates that homeowners have every right to expect, because most systems aren't commissioned. Study after study confirms this.

HVAC contractors are much sloppier than plumbers when it comes to designing a leak-free system, and HVAC contractors rarely perform testing.

Many steps are necessary to ensure a good installation of a residential ventilation system. I agree with the basic premise of your comments. (I assume that your mention of "Andy Kosick's solution" is a reference to Andy's recommendations in Comment #12.) If you install a system as Andy Kosick recommends, and commission it properly, you'll get good results. I already said as much in Comment #14.

The average homeowner will not get good results, however, if he or she asks an HVAC contractor to do as Andy Kosick suggests, because the dampers will be misplaced or forgotten, and no one will test air flows. Moreover, the first technician who does any repair work on such an HVAC system will not understand the reasons for the required dampers, and will ignorantly remove them. Trying to combine a ventilation system with a heating and cooling system, and expecting the average heating contractor to understand how residential ventilation systems work, is a fool's errand.

It is my sincere belief that if the ventilation ductwork is kept separate from the heating and cooling ductwork, there is a higher likelihood that the ventilation system will work -- and that the fresh air will be delivered where it is needed, and that the stale air will be exhausted from the rooms where exhaust is expected. Moreover, there is a better chance that contractors doing repair work on the heating and cooling system won't mess up the ventilation system performance.

This advice may not apply to you, however. You have an engineering background and will be (I hope) carefully commissioning your system. You are the ideal candidate for the Andy Kosick approach. Good luck.

The bottom line is that installers of HRVs or ERVs can use a variety of different ducting approaches. If the equipment is conscientiously installed and properly commissioned, it will work. Some ducting approaches have disadvantages, in my opinion, but in all cases, the most important steps are sealing the duct seams, measuring the air flows, and ensuring that the system is balanced.

Martin sorry my bad obviously I ment to say Andy above for the new article. Thanks for your suggestions. I will contact Allison when I have a final floorplan. Hopefully he knows a capable HVAC contractor in the DC area.

Hi All:

An ASHRAE-calculated 50cfm may be right for a house, but 8-10 cfm may not be right for a bedroom. Cococchio, I don't know your house plan or ductwork layout, but my guess is you have supply registers in nearly every room to maintain uniform thermal comfort with your heat pump. If you had provided ventilation supply air ONLY to bedrooms (and other spaces that have doors), the air flow would have been higher.

By day, unoccupied bedrooms will have very few contaminants and ventilation supply air will "cascade" through other living spaces on its way to return locations (baths, kitchen). At night with occupied bedrooms, CO2 et al is flushed out and carried through typically unoccupied spaces (living, dining, etc).

I understand the reluctance to seemingly duplicate air duct work, and it is hard to justify the additional cost when electricity is so cheap and a standalone H/ERV is not. But as Martin mentions, it indeed is optimal.

Does anyone have data about shortened service life of heating/cooling systems when blowers run 24/7?

I'll add my recommendation for Allison Bailes and Energy Vanguard. He is terrific!

If creating a dedicated duct system as recommended above, how cool/warm is the incoming air and is that a problem? I know that the ERV transfers heat from/to the exhaust air, so that the incoming air is warm in winter and cooler in summer than the outdoor air, but I assume it's not as warm or cool as the indoor conditioned air. Is having a dedicated vent blowing cooler/warmer air noticable or a problem? I'm trying to decide between dedicated duct system and using the existing HVAC ducts. Thanks.

Log in or become a member to post a comment.

Sign up Log in