Image Credit: John Hartman - Fine Homebuilding magazine

John Metcalfe’s San Francisco renovation included the installation of two tankless water heaters and a small circulation pump in his four-story, 3,200-sq. ft. home. The water heaters, connected in series, are located on the second floor, which is a more or less central location.

His hot-water problems should be over, right? Except they’re not.

“We now wait for up to two minutes for hot water in the kitchen and upstairs shower,” he writes in a Q&A post at GreenBuildingAdvisor.

The reasons for the long wait, and the best ways to correct this problem, are the topics for this Q&A Spotlight.

Longer waits are the norm

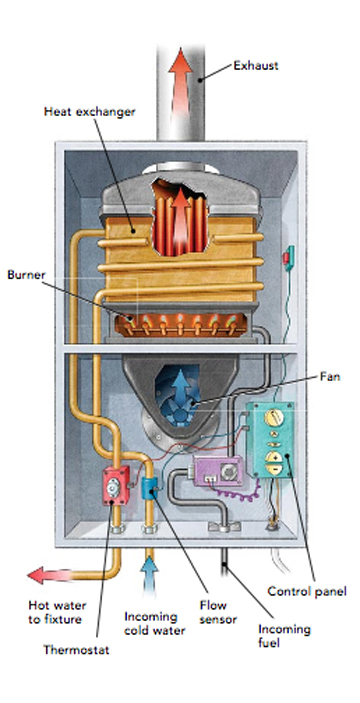

Traditional tank heaters keep water hot all the time, leading to what are called standby losses but also making hot water available at the turn of a tap. Not so with tankless heaters, which begin heating water only when a faucet is opened and water begins to flow.

“Different brands of tankless water heaters perform differently,” writes GBA senior editor Martin Holladay, “but in general you will have to wait a little longer for hot water from a tankless water heater than from a traditional water heater with a tank.”

Holladay notes that Metcalfe’s wait for hot water would probably be shorter if he went back to a tank-style heater. “Other ways to decrease your wait include moving the water heaters closer to the bathrooms and kitchen, and decreasing the diameter of the hot water lines,” he says.

Holladay writes that Metcalfe should make sure that his circulation pump operates by a switch located in the kitchen or bathroom. This is a less wasteful option than either a continuously operating pump or a pump on a timer. Switched pumps bring hot water to the point of use without…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

8 Comments

Marketing and design ...

Marketing: almost off every website selling Tankless you can read about how much energy you are going to save... this influences greatly homeowner who are trying to be green or efficient and pushes them to purchase something that might not be fit to save a single cent on their current or new insallation .

We will need to address and educate about the purpose of tankless water heaters,

and the standby losses value$$ incurred by electrical tank heaters.

System design for quick hot water is the most influential factor as we have again experienced here.

Then again ( sorry if i repeat myself alot ) , heating dominated do not loose much by using regular tank water heaters, and cooling dominated should seriously consider HPWheaters inside their building envelope as discussed with Martin in a another thread.

Now where does it leave a place for tankless ??

On another note, i have used ( unsuccessfully) a Stievel-Eltron Tempra 36 ( 36KW i believe )

and i can tell you that they mention instant ( almost ) hot water and it is what it does.

I've used it while it was still hang on the wall, to fill up hot water pails ( from a 1ft connection distance from the unit ) and the water was hot within 1-2 seconds.

I do not know if their other smaller units achieve the same result

( albeit within their flow range ) .

Now we still need for someone to get out and tapp in a -25C compressor unit from Fujitsu or Mitsubishi and use it as water heater!! :p

steibel and design

I installed a Steibel eltron 24 (kw) for our passively designed house, and it supplies floor and domestic water heat. We use a water to water heat exchanger for the floors (Massachusetts home), and it supplies plenty of hot water for daily baths, and dish and laundry washing requirements (for 2 person household). The only drawback it has over a gas fired version which I used in another house is that the temperature is maintained by a flow reducer if you ask for too much volume. the 24kw supplies about 3.5 gallons per minute at a sufficient increase for plenty hot water (the gas fired version supplies almost 7 gallons/minute). But you cannot run your tub and laundry at the same time without a large decrease in volume allowed. As for the person who has a 4 story home and waits 2 minutes for hot water, obviously the plumber put the units too far away for quick hot water, and I do not agree that a tank heater would be much quicker. The hot water still has to travel the same length of pipe. With exception of the 1 or 2 seconds it takes to start getting hot water from the instant heater, the length of pipe is the same. 2 heaters in series is odd though too, and if anything, the heaters should have been installed like mentioned (1 for floors 1/2 and 1 for floors 3/4) or in parallel. Since this is a large house we are talking about, each floor probably should have had its own instant heater within maybe 20 feet of pipe from the need at most. The circulator pump is probably a cheaper way to solve a problem which will cost the owner more in the long run since it will run the heaters much more.

the moral of the story - if you want it done right, do it yourself (or at least monitor the plumber closely).

Recirc Pumps and Tankless Heaters

I've experimented with this combination three different times. I found it to be successful only once. The most common problem is not enough pump flow to turn on the heater, but it's not the only issue. The controls and operational modes of these heaters are unpredictable enough for me to say that don't expect either the Metlund or Chilipepper to work correctly. I've even added buffer tanks without reliable success.

@ Jin

Someone is making Fujitsu (?) based mini split water heaters in Australia. Just need to get them to the U.S. Seems too good to be true.

totally disagree with this article

I couldn't disagree with this article more, from my experience it's totally bogus. I live in two houses, one with a hot water tank, the other with a Paloma tankless water heater. With the tank, I have to let water run for at least two or three minutes to get hot water, wasting several gallons of water each time I need hot water. With my tankless water heater I have to wait only a few seconds. Also, the tankless water heater is much less expensive to operate than the wasteful energy consumption of always on. Over the period of a single year the difference in water and energy efficiency is dramatic. Multiply this by several million New England homes and you gain a sense of how unbelievably irresponsible American building standards are in comparison to more enlightened countries in Europe.

Response to Roger Brisson

Roger,

You are correct that a tankless gas water heater will save energy compared to a tank-type gas water heater.

However, there is only one reason that explains why you have to wait so long for hot water from your tank-type heater: obviously, that heater has a longer pipe run (or a larger diameter pipe) than your tankless heater.

The most important things you can do to reduce your wait time for hot water is (a) to install the water heater as close as possible to the point of use, and (b) to use the smallest feasible pipe diameter.

Many brands of tankless water heaters have a slight ignition delay that irritates users. For tank-type heaters, however, ignition delay is irrelevant to the topic at hand, because the tank stores water that is (almost) always hot.

There are few simple answers to complex problems

or as H.L. Mencken said, "For every complex problem there is an answer that is clear, simple, and wrong."

I have 2 experiences with DHW. For the last 22 years, my 125 BTU/hr Aquastar (pre Bosch) has provided wonderful hot water...as long as I was alone and no guest tried to do dishes while I was taking a shower. I've put in a rebuild kit, a few thermocouples and flushed it with vinegar as the water I was using was quite hard. But there is only 25 feet of copper pipe in the whole hot water system, so 12 or so in the DHW.

I now have a large house with DHW provided by the sidearm on my Buderus gas boiler. In the winter, the water is preheated from the heat storage tank that my wood boiler uses. I made the most of home run pex plumbing and as a result, have a long wait for hot water, particularly at the kitchen sink. To get around this problem, last month I installed an EcoSmart (don't you love marketing!) 11 kW demand heater under the sink. It's fed by the tank from the boiler so it only preheats the water and it solved the problem. I still lay awake at night wondering how much heat is being lost from the hot water cooling in the long pipe, but that's just an indication I have too much time on my hands.

But it does make me think that a recirculating system must waste a LOT of heat. Even with insulated pipe, the R-value is quite low, the delta T high and the area of heat loss considerable. So instead of just losing the heat from hot water as it cools, the heat is lost continuously. Fine in the winter, we use that heat, so so fine in the summer when we are either praying for less heat or actively moving that heat back outside.

Hello - Insulation!!

@Robert, thank you for being the first to bring up what should be one of the first considerations in this discussion, that of insulation and piping material. Needless to say, too bad it NEEDS to be said in this case, pipe insulation is a critical component in a successful tankless installation. What's more, absent from the conversation is that a tank-style WH operates on the premise of maintaining a temp setpoint for a large reservoir of water that includes the entire column of water that runs to each and every HW fixture and the pipe is part of the heat transfer equation. DHW offers the significant energy savings that it does largely because of the fact that the distribution acts as a heat-sink that is being continuously battled by the thermal mass of the water and containment of the tank-style WH -- DHW chooses not to fight the loss of heat until the water is required. Assiduous care in how well and how much the piping is insulated will yield much better system performance, duh. We are talking about a hot water system, so we must approach it holistically.

My brother's DHW system had the on-demand wait problem because his DHW is ~40' from his bathroom, so he called his plumber back, and the plumber installed a small pump + switch for a crossover solution at the terminal point of use, and that solved the problem. They simply press the button for about 2 seconds, and the water is warm enough to start using without any water loss. We live in California, so water conservation is a big, big deal.

In my 125KBtu DHW system, our 2-bath house is over 100 years old and there are pipes that I cannot access without tearing walls open, so we are still suffering the fact that our galvy pipes are giving up our heat. Our system is located as centrally as possible and our longest run is about 25'. We have 2 big problems: 1) We experience the "thermal sandwiching" in the 1st minute after acceptable running temp is achieved, 2) our Thermidor/Bosch dishwasher has only a 1/4" feed line, which limits the HW flow enough to keep the DHW kicked on and that leaves our energy efficient dishwasher to electrically heat its own water, not good.

The correction plan is to add the light switch initiated recirc pump plus flow meter activation, and ongoing efforts to improve distribution insulation. To the end of improving insulation, I'll probably include PEX.

Log in or become a member to post a comment.

Sign up Log in