Looking ahead to insulating his new house, Wiscoguy says he’s planning to use an R-14 layer of exterior insulation along with mineral wool in the stud bays. But there’s a sticking point—cost.

Quotes for fiberglass insulation have come in at about $10,000. Mineral wool (sold commercially by Rockwool and Knauf) would cost $16,000.

“It has a very modest gain in R-value but I do like some of the other properties,” Wiscoguy writes in this Q&A post. “Also, next to no one in my area wants to do it, which pushes my schedule back further.”

“I’m having a hard time justifying the increase in cost,” Wiscoguy adds. “Any thoughts?”

That’s where we start this Q&A Spotlight.

Installation is key

To John Clark, the answer to that question hinges on how well the insulation is installed.

“Depends on the quality of the installer,” he says. “If you can hit Grade 1 with fiberglass batts, then pass on the mineral wool.”

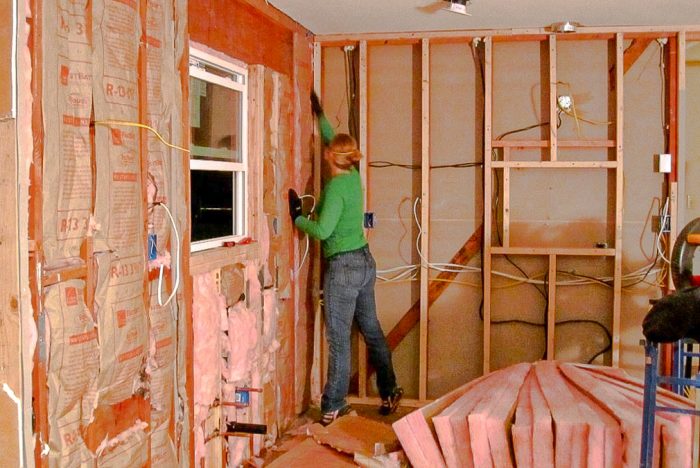

To illustrate, Clark refers Wiscoguy to a bulletin in the Building America Solution Center. A “Grade 1” installation means that the insulation, no matter what type, should fill wall cavities uniformly, filling each bay side to side and top to bottom “without substantial gaps or voids around obstructions.”

Gaps and voids are typically the failing of batt insulation, not the insulation itself, a point amplified by Michael Maines.

“With enough exterior insulation to prevent condensation, an airtight layer at the sheathing, and a reasonably airtight layer at the interior, I don’t think the choice of insulation makes a big difference,” Maines says. “I usually go with cellulose for its low-carbon aspect, but with mineral wool and fiberglass having similar levels of embodied carbon, I don’t see a reason to prioritize mineral wool.”

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

11 Comments

Before the homeowner goes down the self-install route, double check the pricing. Insulation contractors get great prices because they buy in such volume; often their installed cost isn't that much worse than your cost just to buy the insulation.

“[Deleted]”

“[Deleted]”

As I mentioned in a letter in response to another article, I've opened up walls and ceilings for renovation in 50-60 year old buildings and found the fiberglass batts significantly or completely compressed. Was it poor quality fiberglass or poor installation? I don't know but attic installations just required laying the batts down so I don't think the latter had anything to do with it. I imagine the newer higher density fiberglass is less problematic in this way. I prefer Rockwool because it is easier to work with, is more resistant to insects and rodents, more durable, hydrophobic - and most of all - because it is much more fire resistant than any other insulation (melts at 2100 degrees F, as opposed to under well 1000 degrees F for any other type of insulation; with a typical house fire around 1100 degrees). Being an owner of rental properties, the last quality undoubtably affects my thinking a great deal. Insurance will replace a building, lives not so much.

Regardless of price (not much of difference here in Upstate NY for similar R-values), and all of the reasons expressed by Robert F. in favor of mineral wool, there is one important aspect no one has mentioned. The sound deadening component mineral wool brings to the table wins hands down over fiberglass. We are builders who have been living in a zero energy home for 6 years that was insulated with Rockwool; R15 x 3 in the walls. If the windows are closed in our home, we do not hear rain storms, high winds, vehicles driving by, or coyotes howling across the road. It is actually pretty darn amazing how mineral wool (and I would guess DP cellulose as well) can quiet the interior living space. So for folks living in a city, on a busy suburban street, in an apartment complex, or in a rural environment like mine, mineral wool will always be our choice over fiberglass.

In a fully enclosed wall cavity, the difference in the sound attenuation between mineral wool and high density fiberglass batts isn't noticeable.

I recently sold the fixer upper I bought 30 odd years ago. I gutted it and redid everything except the structure, and was proud of the job I did on the insulation,(fibreglass). When a section of the wall was exposed I was horrified to see the mess the mice and squirrels made. They come in via the attic and tunneled straight down to wherever they felt was good. When I started planning to build a new house I was sold on rockwool but in the last two years the price of everything ballooned and paying triple the price for rockwool seemed like it might be too much for me. If it could discourage the rodents though I might rethink it again.

On another issue I found that old electric bread knives cut a clean line through fibreglass insulation without compressing it.

Nils,

Discourage maybe, but rock wool doesn't stop rodents. I've found nests in left over batts I had piled up in a crawlspace.

I used rock wool on recent projects and found that it is (a) much easier to install correctly because rock wool is much denser than fiberglass and 'molds' kind of like clay so you can fill gaps easily, This is not possible with fiberglass which is significantly lighter and 'fluffier' (b) the improvement in R-value: R-4.1 compared to fiberglass at R-3.5, an improvement of 17%. Does this improvement in R-value balance out the >25% cost for rock wool? Yes, for two reasons: (1) The r-value combined with the significant improvement in installation quality. It is much easier to achieve a 'Class A; installation with rock wool, compared to fiberglass, and (2) Space within walls is limited - often to 3.5 inches. So there is a hard limit on the maximum R-value. There isn't room to add more. The ONLY way to achieve R-15 in a 3.5" wall cavity is with rock wool -- and you are much more likely to achieve the best result.

A caveat: As others noted, the fibers from both rock wool and fiberglass are irritating. Research shows they may also be carcinogenic, like asbestos fibers. So you don't want to breath them! Wear a GOOD dust mask - not the cheapos with a rubber band on the back. 3M makes good dust masks for construction, available at HD and Lowes. We also wear cheap Tyvek 'painter's suits' and gloves for larger jobs, to keep the fibers off of our clothes - and to avoid bringing the fibers home.

RE sound attenuation, Johns Manville manufactures fiberglass and rock wool batts -- and states "...the difference in acoustical performance is so minimal that humans would not be able to distinguish a difference between the two materials in a wall cavity." See: http://www.jm.com/en/blog/2021/march/head-to-head--mineral-wool-vs--fiberglass-/ Note, however, that JM did not specify whether dense or standard fiberglass batts were used in this comparison, and sound reduction is much more complex than simply which type of batt you use in a wall.

I hope this is helpful,

Mark

Mark,

From Scott's article above:

"But these differences between mineral wool and fiberglass can be minimized by choosing high-density fiberglass batts, which provide R-15 in a 2×4 wall"

If rock wool is denser than fiberglass bats it will attenuate a different range of frequencies. The little secret of custom audio installations is that the typical stud and fiberglass wall actually resonates at 100 HZ; thus explaining why so many systems have muddy bass.

Acoustics are physical phenomena, as are heat gradients and other thermodynamic phenomena. But each, in practice, is modulated by human perception. Here in Northern Minnesota that insulation system that best retards heat transfer is psychologically felt as warmer; we appreciate those methods and materials that create a low sloped heat transfer gradient.

Log in or become a member to post a comment.

Sign up Log in