Image Credit: Fine Homebuilding

I’ve been paying attention to energy-efficiency and air-sealing tips for many years, but I still learn something new every week. This week, I learned a very useful tip from my fellow Fine Homebuilding editor, Justin Fink.

Justin wrote a great article on canned spray foam, “You Don’t Know Foam,” that appeared in the current issue of Fine Homebuilding.

I’ve known for years that one-component spray foam (unlike two-component spray foam) is moisture-cured. I’ve also known that freshly installed foam pulls moisture from the air to cure, and that builders working in very dry climates (like Nevada, New Mexico, and Arizona) know that it helps to mist a little water on surfaces before using one-component canned spray foam.

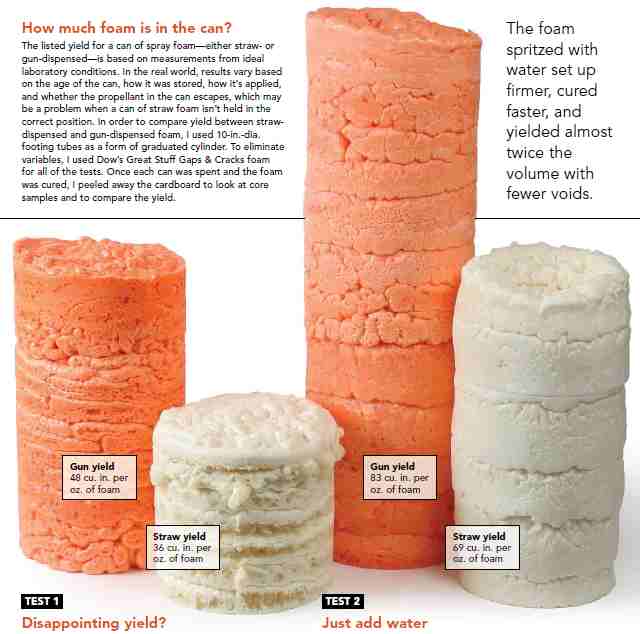

I didn’t realize, however, that misting water before using canned spray foam can make a significant difference in New England. Nor did I realize that misting water can double the yield from a can of spray foam.

Quotes from Justin’s article

Here is what Justin wrote:

“Polyurethane cures by reacting with the moisture in the air. If very little or no moisture is available, the light and fluffy foam will collapse into itself as it cures. A light spray of water applied to surfaces before filling voids with foam will go a long way toward getting foam to cure properly.

“This is especially important when working in areas of low humidity, but it’s also best practice when filling deep voids. In the case of deep voids, apply the foam in layers, misting lightly between them. It only takes an ounce of water to cure an entire can of polyurethane foam, so think in terms of a spray bottle, not a garden hose.

“Manufacturers of some cans of foam, both straw-dispensed and gun-dispensed, recommend misting water either…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

8 Comments

Cold air is dry air

I also saw that article last week, Martin, and it made me recall one of my first air-sealing jobs. I was working in an attic in January here in the Atlanta area, and I saw the foam from my gun get thin and wispy as it cured. It didn't collapse, but that's where I learned the misting trick.

You wrote:

I believe it was your last article when you talked about how cold it gets in Vermont, and that's the key. The psychrometric chart makes it clear that cold air is dry air, so New England air is really dry in winter.

Response to Allison Bailes

Allison,

I understand the psychrometric chart, and I certainly realize that indoor air is dryer during the winter than during the summer.

But I've been using canned spray foam for years, and it always cured just fine. So I concluded that the foam was finding all the moisture it needed to cure.

I had no idea that misting a little water would double the yield from a can of foam. That's the part that really surprised me.

So, Allison -- over the past few years, have you always misted surfaces with water before using canned spray foam? If you have, good for you. I haven't.

No, I haven't.

I knew you knew that but wanted to make the point for other readers.

After learning firsthand about misting, though, I didn't apply that lesson consistently. I didn't realize the quantitative effect of adding moisture, just that it helped in winter, so I only carried the water with me when I noticed a decrease in the quality of the foam. After reading Justin's piece, I now know that I should have done it more consistently.

Also, since I'm not in the contracting business anymore, I haven't used my foam gun in a while. In fact, it may not even work anymore since I haven't cleared it of foam.

Carefully with the H20

I would be cautIous with the water. A couple winters ago on a very cold day I spray foamed in all the windows on a new apartment building. The inside of the building was heated and there was condensation present on the tops of the window jambs. Long story short the spray foam went bananas and ended up bowing several of the window frames. Now I always make sure windows are nice and dry.

Access denied

Both of the links for the complete Justin Fink article, that appear at the end of Martin's blog posting, take me to pages that allow access to members only. That is not unreasonable, but I suggest noting it with the links. On the other hand, if the links were supposed to allow access to anyone reading this blog posting, then something was amiss when I tried.

Response to Derek Roff

Derek,

The reason I wrote this freely available blog was to share information from Justin Fink's article with people who might not have access to Fine Homebuilding.

It's well worth subscribing to Fine Homebuilding magazine, in my opinion. Even when I was an indigent hippie, long before I imagined that I might be an editor at the magazine, I subscribed.

Fortunately, GBA offers free 10-day trial subscriptions to our site. This free trial will grant users access to all GBA Pro pages. Details can be found here:

https://www.greenbuildingadvisor.com/join

If you've used up your free 10 days, access is available for $14.95 per month.

How had I not read this before?

This. Is. Awesome.

It also makes me like 2 part spray foam a little better...

Dear Martin and the GBA Team: Here is another key tip you should add to this article on canned spray foam -- the cured foam is very flammable and will ignite at just 240 degrees F. This is significantly lower than the ignition temp for wood. This is also true for the versions that have "Fire Block" on the label, e.g. Great Stuff and 3M. Canned spray foam should never be installed near any source of heat, e.g. recessed lights, exhaust vents, furnaces, ovens, heaters, fireplaces, etc. It is banned for "fire stopping" (e.g. sealing holes around wiring and pipes) in commercial construction, and smart residential building inspectors can fail your inspection if they see it in a home. We always use true fire resistant caulk for fire stopping, e.g. 3M CP 25WB Plus.

Log in or become a member to post a comment.

Sign up Log in