Image Credit: Image #1 and Image #2: Vosla GmbH

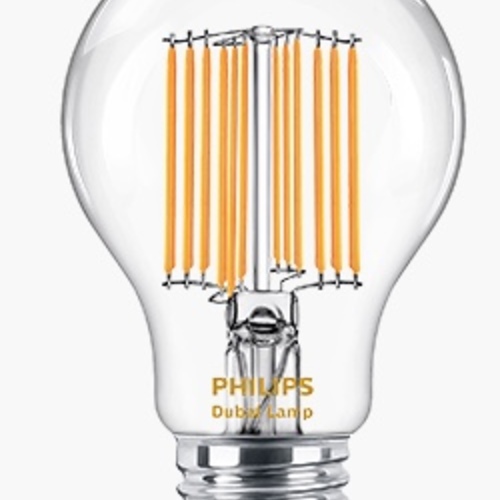

Image Credit: Image #1 and Image #2: Vosla GmbH A historic restaurant in Plauen, Germany, replaced their incandescent bulbs with LED filament bulbs once the owners were convinced that the new lights would not ruin the cozy atmosphere. The new bulbs are pictured here. Thermal images of two LED bulbs, each of which draws 5.5 watts of power. The bulb on the left is an LED filament bulb, and the bulb on the right is a Cree LED bulb. The bulb on the left has a relatively even temperature that peaks at 48.5°C (120°F). It produces 608 lumens at an efficiency of 109 lumens/watt. The Cree bulb has its temperature peak at its heatsink, at around 68°C (154°F). It produces 467 lumens at an efficiency of 87 lumens/watt.

Image Credit: Image #3: Passmark A graph from the Swedish report, showing measured cost vs. efficiency. Both filament and conventional LED bulbs are plotted on this graph. The colored boxes indicate projections by the European Commission. More than half the LED filament bulbs exceed the 2018 predicted efficiency of 105 lumens/watt, but costs vary widely.

Image Credit: Image #4: Swedish Energy Agency

When it comes to providing a drop-in replacement for old-fashioned incandescent bulbs, there are a number of technical and aesthetic challenges that are difficult to address with LED-based technologies.

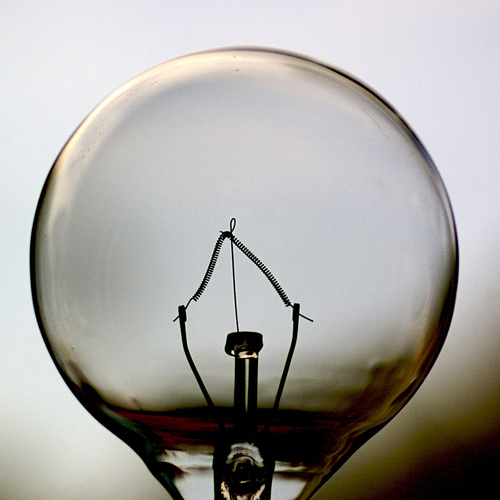

Conventional LED bulbs are constructed from a small number of high-intensity LED chips, mounted inside an enclosure with suitable optics that spread the light in the desired pattern. LEDs are very sensitive to heat, and the kind of high-power LEDs found inside of conventional LED bulbs generate a lot of it. Large metal heat sinks are required to conduct the heat away from the LEDs and dissipate it into the surrounding environment.

The first LED bulbs adopted a ‘futuristic’ look in order to distribute the light from LED chips in a reasonable pattern, while keeping them sufficiently cool through the use of large heat sinks.

As technology and manufacturing techniques have progressed, it has become possible to shrink the heat sink enough to produce bulbs that increasingly come closer to emulating the look to a typical frosted incandescent bulb of old. (1) Variants that use optics such as light pipes are available that attempt to emulate the clear incandescent bulb look. Overall, efficiencies in the 70-90 lumen/watt range have become common for LED replacement bulbs.

Smaller form factors, such as the candelabra-base bulbs one might find in a chandelier or pendant light, are much more difficult to emulate. The required heat sinks can result in a bloated shape that does not resemble the lights they are intended to replace.

Recently, while researching lighting options for an 1850s Italianate building that we are renovating, I stumbled upon a new kind of LED bulb that took a completely different approach compared to the “high-powered LED chips + heat sink + optics” of conventional LED bulbs. These so-called “LED filament” bulbs looked almost exactly like incandescents: a glass bulb encasing a little glass tower inside, with tiny metal arms holding up a series of “filaments” that glow brightly when turned on. Other than the fact that the “filaments” appeared yellow when the bulb was off, there were no external cues that these were LEDs.

Sellers of these LED filament bulbs made some amazing performance claims: lifespans of 25,000 to 50,000 hours, color rendering index above 80, and outstanding efficiencies near 120 lm/W. They all seemed to be relatively unknown brands, seemingly sourced from several anonymous manufacturers in China. Likewise, these bulbs were fairly new to the market, having been introduced roughly around early 2013 to the European market.

Could these things be for real? What’s the catch? I did quite a bit of research into them, and ended up with a fascinating story.

A unique construction

There are two characteristics that define LED filament bulbs: Novel filament-like LED structures, and the use of a highly thermally conductive gas such as helium (2) to allow the glass bulb itself to serve as a heat sink.

The filaments are typically about an inch long, and are formed by bonding dozens (3) of tiny, low-power LEDs in series on thermally conductive substrate. This is achieved through a process called Chip On Glass (COG), similar to the way LCD panels found in televisions or smart phones are formed. Typically, these tiny chips are mounted on a strip of sapphire, ceramic, glass, or metal. The ideal substrate would be highly thermally conductive, and transparent in order to allow light to be radiated in all directions. Sapphire is transparent, thermally conductive, and expensive. Glass is less thermally conductive, but cheap. Metal substrates are cheap and thermally conductive, but not very transparent.

Once connected together in series and bonded to a substrate, the LED filaments are encased in a phosphor-impregnated silicone. The phosphor used in white LEDs (4) is a characteristic yellow color. Different formulations of phosphor give distinctive color characteristics to the light (e.g. cool white, warm white, etc.). Some filaments contain a small number of red LEDs to improve color rendering (5). This video (in German) nicely shows the pattern of blue and red LEDs in a dimmed filament.

Each individual LED in a filament is tiny and low-powered, drawing only ~10 mA of current. This is very small. For comparison, common 5 mm packaged LEDs such as those used as an indicator lights on electronic gadgets are usually rated at 20 mA. An entire filament composed of 28 of these tiny LEDs draws about 0.8 watt. Nominally, each filament is considered 1 watt when constructing a bulb. That is to say, a 2-watt bulb will use two filaments, a 4-watt bulb four filaments, an 8-watt bulb eight, and so on. At a typical efficiency of 120 lm/w (6), each filament dissipates about 0.5 watt of heat (7) into the surrounding gas. Each individual LED within a filament produces less than 0.02 watt of heat. This low power density of LEDs suspended in thermally conductive gas is the “secret sauce” that allows such a bulb to function safely without a heat sink. Some manufacturers claim a junction temperature of 60°C in the individual LEDs under normal operating conditions, which is quite good. For comparison, temperatures above 120°C are damaging to the LEDs.

The power supplies (drivers) for LED filament bulbs are typically small and simple. The largest physical component is usually an electrolytic capacitor, which serves the purpose of reducing flicker or ripple in the light output. All the driver circuitry is hidden within the screw base of the bulb. For smaller “candelabra” base bulbs (E12, as used in the U.S.), there is usually not enough room in the screw base to accommodate a smoothing capacitor, so manufacturers either go without one (at the expense of some flicker which may be visible in peripheral vision), or incorporate a plastic “extender” between the screw base and the glass bulb to make room for the capacitor. There are several “tear-down” videos which explain the physical construction of these bulbs:

â— A19 bulb with plastic extender

â— Candelabra-base bulb with plastic extender

â— All-glass candelabra-base bulb

European analysis

Although they have not penetrated the North American market to a significant degree, LED filament bulbs have been spreading rapidly across Europe over the last two years. A November 2014 report by the Swedish Energy Agency tested a variety of these bulbs to validate their marketing claims, and compared their cost and performance to the expected technological progression of LED bulbs as set forth by the European Commission.

The study included a variety of clear, omnidirectional LED bulbs (i.e. non-frosted) for comparison. Several models were chosen for testing, with 10 samples tested for each brand of bulb. The LED filament bulbs were measured (8) to have an average efficiency of nearly 107 lm/W across all brands. Half the LED filament bulb models measured at or above 110 lm/W.

Efficiencies were measured at about 5% lower than the claims on the bulb’s packaging. In comparison, the conventional LED bulbs had an average of just over 75 lm/W efficiency, still about 5% lower than manufacturer claims.

The LED filament bulbs were as efficient as the European Commission projected for the industry in 2018. Cost of the filament bulbs just about on par for the 2014 predictions, at about slightly more than 15 euro per 500 lumens. Overall, the LED Filament bulbs were 40% more efficient and 20% more costly than the conventional LED bulbs included in this study.

Testing the light characteristics such as color rendering index showed that the LED filament bulbs had high light quality (> 80 CRI) that overall didn’t seem any better or worse than the conventional LED bulbs included in the study. Long-term durability testing is ongoing, with a followup report for lumen maintenance after 6,000 hours due in May.

Initial results were encouraging. Though a few bulbs failed in the initial 200 hour “burn in” period due to manufacturing flaws or physical damage (well within the warranty period), initial results show that the LED filament bulbs have been faring well so far.

Energy Star certification

Earlier this year, a startup called AXP Lighting became the first distributor to have a line of LED filament bulbs Energy Star certified for sale in the U.S. For LED bulbs, Energy Star certification is a big deal. Unlike most products, where an Energy Star rating merely indicates a certain level of efficiency, LED bulbs must meet a series of strict light quality, longevity, and technical requirements as verified by independent testing in an accredited facility.

Some key testing requirements for Energy Star certification for general-purpose omnidirectional bulbs include:

- A 6,000 hour duration test for lumen maintenance and color drift. General-purpose bulbs must maintain at least 91.8% of their brightness at the end of the test, which predicts an end of life (70% output) at 25,000 hours. Higher claims of bulb life must be backed by data (i.e. less measured drop).

- Minimum Color Rendering Index (CRI) of 80, with an R9 red level of at least 0 (yes, values can be negative for this). Color temperature must be accurate within a specified limit.

- Omnidirectional light pattern, within specified limits.

- Efficiency must measure at least 50-55 lm/W, depending on bulb wattage.

Specifications for certified Energy Star bulbs are available on the Energy Star web site. At present, the most efficient “general-purpose replacement” Energy Star bulb of any kind is a 7-watt LED filament model, certified for 890 lumens at an outstanding 127.1 lm/W, though with a very cool 6500k color temperature. The most efficient warm white (2700k) Energy Star bulb of any kind is also a 7-watt LED filament model, certified at 115.7 lm/W. Both of these bulbs currently retail for $13.99.

Analyzing the entire Energy Star dataset for LED general-purpose replacement bulbs (9) in the A19 (standard medium screw-in bulb) form factor, the LED filament bulbs have an average efficiency of 109 lm/W. The conventional bulbs (everything else in the dataset) average to 76.5 lm/W. This is remarkably similar to the results from the Swedish Energy Agency report, with 107 lm/W average for filament bulbs, 75 lm/W for conventional. The caveat is that the Energy Star dataset contains filament models from only a single manufacturer, while the Swedish Energy Agency report included several.

Conclusion

These are very interesting bulbs. Energy Star certification and analysis by the Swedish Energy Agency have largely validated claims that these bulbs can produce great light at above 100 lm/W efficiency, and ought to have lifetimes comparable to conventional LED bulbs with a heat sink. Even completely ignoring their aesthetic similarities to tungsten-filament bulbs, their performance characteristics make them a compelling choice for general-purpose lighting.

In terms of cost, the Swedish Energy Agency report indicated that they were about 20% more expensive than conventional LED bulbs. However, prices varied widely; and there didn’t seem to be any particular relationship between price and performance. For example, the cheapest LED filament bulbs in the study, a no-name “star trading,” was less than half the average price, yet had above average efficiency, and had color rendering and consistency that was on par with all the others. One of the more expensive bulbs, the German vosLED, was almost twice the average price, but offered outstanding color rendering (CRI above 90, with R9 red level above 60) at nearly 110 lm/W, and appears to be made in Germany.

Here in the U.S., cheap no-name LED filament bulbs are available from online marketplaces such as Amazon, eBay or Ali Express, with many retailers selling shipping direct from China for little or no fee. It is easy to find bulbs for $5-$10 in the 2 to 8 watt range (sometimes even less), but it unclear how many of these have basic UL safety certification. There appear to be a handful of U.S.-based importers that sell under various brand names (such as Spotlite USA, Lighting Science, Archipelago Lighting , AriusTek, AXP, etc.). Many of these appear to be UL listed, with AXP selling the only LED filament bulbs to date that have earned Energy Star certification; 2 to 8 watt bulbs in this class can be found in the $10-$15 range from U.S.-based online retailers (though it’s easy to find sellers who will offer them for more than that).

For me, these are the first LED bulbs that combine all the features I like: high efficiency, clever design, reasonable cost, and an early 20th century incandescent aesthetic that would fit in well with our Luddite decor.

Footnotes

1. Some newer, inexpensive designs such as the Philips Slimline and Cree 4flow use circuitboard material as a large, internal heat sink.

2. Helium and hydrogen are about 10x more thermally conductive than other gases, due to physics beyond the scope of this article. Bulbs may contain a blend of helium and a cheaper relatively inert gas such as Nitrogen. Due to Helium’s propensity to escape confinement, a hermetically sealed glass bulb is an ideal enclosure. This is why filament LED bulbs are made out of glass, not plastic.

3. 28 LEDs per filament is typical.

4. There are two distinct types of white LEDs. So-called RGB LEDs contain three primary color LEDs that blend to form white. This is problematic in real life, as different aging qualities between the LEDs can cause the color to drift slightly in hue over time. Most white LEDs are the phosphor variety, which use blue LEDs. The blue light strikes a yellow phosphor, causing it to emit light of various wavelengths and appear white to the human eye.

5. The color spectrum of phosphor-based white LEDs is typically deficient in red and cyan. Reds are particularly important for viewing certain subjects such as meat and flesh tones in an appealing manner. Some phosphor formulations can enhance reds, but a more efficient way to enhance the red spectrum is to mix in a few red LEDs.

6. The efficiency of an LED chip is always higher than the measured efficiency of the whole bulb. Whole bulb efficiency includes losses from the power supply, as well as through the optics. Glass is not 100% transparent.

7. A 100% efficient white LED would theoretically produce somewhere between 250-370 lm/W, depending on its light spectrum. Here, the assumed ideal efficiency is 310 lm/W.

8. The results are in the report, but are mixed with the conventional bulb results. This spreadsheet contains data for the LED filament bulbs, while this one has the conventional LED bulb data.

9. Downloaded from the Energy Star advanced search tool, filtering for LED A19 bulbs.

Aaron Birkland is a homeowner in upstate New York who works as a research computing consultant at Cornell University. He and his wife Johanna are in the middle of renovating an 1850s Italianate farmhouse in Richford, New York, undoing the results of an unfortunate 1960s-1970s remodel that could serve as a textbook case of bad building science decisions.

Editor’s note: The thermal images shown in Image #3 are reproduced with the permission of Passmark from reviews of the LEDisong LED Bulb and the Cree 6W Dimmable WW bulb.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

16 Comments

Great article. Minor correction ...

Great article--thanks for the research!

Minor correction: looks like a dash is missing in "Efficiency must measure at least 5055 lm/W, depending on bulb wattage." Presumably that's 50 to 55 lm/W.

helium

I hope the warranty covers loss due to opening the package in an open air environment and watching them float into the atmosphere. Always open the box inside your home so if they are mishandled you can then collect them from the ceiling.

Response to Charlie Sullivan

Charlie,

Thanks for noting the typo. I have corrected it.

Cool

Really neat, had never heard of these and appreciate the post. Another minor typo comment re: 3rd image comparing filament to traditional LED bulb--text refers to both images as "image on the left"

Response to Katy Hollbacher

Katy,

Thanks for letting us know. I've fixed the typo.

Any 12 Volt DC versions?

Very interesting - did you come across any 12 V DC versions?

Response to Andrew Robinson

I've only seen 12V DC versions available direct from China, not from a retailer. They would use a slightly different kind of power supply than bulbs designed for the mains current as it would "boost" the voltage up to >75V in order to light the filaments rather than lower it, and it would not need to rectify the AC.

Here are a few that claim to have 12V DC variants, but there is bit of risk in ordering direct from a Chinese manufacturer or wholesaler.

http://www.alibaba.com/product-detail/Filament-led-bulb-NEW-made-in_1973348954.html

http://www.alibaba.com/product-detail/UL-High-Luninance-3W-6W-SMD_1983600715.html

http://www.alibaba.com/product-detail/E12-Filament-LED-in-12V-AC_60059721668.html

http://www.alibaba.com/product-detail/factory-lighting-chandeliers-led-filament-bulbs_60080703009.html

Thank you

We're using this

Thank you

We're using this informative blog already to order bulbs for a new code cafe.

Aj

CRI and Flicker

Unfortunately, many budget LED bulbs have simplified drivers or are "driverless designs" that have flicker. Even if the 120 Hz flicker is hard to detect, from what I've read the flicker can contribute to eye strain and headaches. I'm guessing that these filament LED bulbs fit into that category, and that the simple driver also contributes to their high lm/W efficiency. The better bulbs have high frequency drivers that eliminate flicker and/or push it above 200 Hz.

What I'd like is an LED bulb with 2700k color temp, CRI 90 or higher (with good R9), no flicker, no audible noise (full and when dimmed), and high efficiency. Ideal would be if it also had "warm dim"--the color temperature gets lower as it dims, to mimic an incandescent bulb. All these things are available, but not yet together in a single product. In the race to produce sub $10 bulbs, the flicker problem seems to get ignored. I'm holding onto my CFLs for a while until an LED bulb appears that better meets these requirements.

Great article.

It goes to show how much work has to go into saving less incremental savings on light production. Currently I have 18 LED bulbs, 3 incandescent appliance bulbs, and 2 CFL left in outside lights. When I switched to CFL bulbs, the savings on lighting were good, but my wife hated them. So let us say the switch from incandescent to LED was from 60 watts per bulb to 11 watts per bulb, a saving of 49 watts each. The switch from these LEDs to 40% more efficient bulbs would save about 4 watts per bulb.

My goal was to reduce my power usage by 50%. I am down by 40%, and the last 10% is going to be the toughest.. It has taken 5 years of dabbling, but is gratifying. As my wife is prone to remind me: Lifestyle change is not an option. The dishwasher and clothes dryer are staying!

Response to Adam Liberman

Actually, the opposite is true - many (most?) of these bulbs have little or no flicker, and can squeeze a fairly sophisticated driver into the screw base of the bulb (perhaps with the help of a plastic extender at the base to make a little more room). The article addresses this:

Indeed, one of the videos shows a flicker-free bulb, look at :43:

https://www.youtube.com/watch?v=25j2C4jq2HI#t=43

Likewise, look at the bottom of these reviews:

http://www.ledbenchmark.com/display.php?id=239&name=Ecopoint+LEDisong

http://www.ledbenchmark.com/display.php?id=327&name=Mirabella+4W+LED+Filament+Classic

In these reviews, the flicker is considered to be 1%. For comparison, their incandescent shows 11%

Of course, the ones with the simplest possible drivers (just a rectifier and resistive or capacitive dropper) do show flicker. For example, this one (the reviewers noted in a separate conversation with me), was poorly made, and didn't seem to be sealed at all - suggesting the filaments might not be adequately cooled, as the cooling gas would just be air. The cheapness of the driver circuitry and the resulting flicker was consistent with the overall quality of the bulb.

http://www.ledbenchmark.com/display.php?id=331&name=littil+3.5W+LED+Filament+COB+Bulb+Large+Round

Response to Roger Williams

The impression I get is that the efficiency of these bubs is a result of the techniques necessary to create LEDs that look like filaments. It wasn't necessarily a goal itself, It was just a happy consequence of the engineering necessary to make the concept work.

For example, light-shaping optics and frosting (to make the light output more uniform) reduce light transmission (and therefore efficiency), but due to the omnidirectional nature of the filaments, they don't need any of that.

Likewise, LEDs operate most efficiently with lower currents. The strategy used to produce adequate light output from the filament while maintaining adequate cooling - a chain of weak LEDs dotted along a long strip - inherently requires low currents.

At least, that's how I see it. Whether or not these bulbs are cost effective over conventional bulbs just on the face of their specs (averaging 40% more efficiency for 20% more $) is another question, as is the value of aesthetics. The answer to this question is probably different for a homeowner than a business owner - who likely has more lights burning for longer, and for whom lighting decisions might part of the overall look the designer is going for (take for example the inn in the 2nd picture of the article, and maybe even the cafe AJ is working on)

Very informative

Been experimenting with the filament type bulbs for a bit. The vintage style Edison's give off the best light still, from what I see. But in busier areas where the bulbs are part of the decor, we have switched to some LED filament bulbs and are happy.

Response to Aaron Birkland

Thanks, that's good to know that many of these have little or no flicker. Unfortunately, I don't see any CRI 90 filament type bulbs available on the US market yet, but I hope they appear.

High CRI

Adam,

Right - While high CRI filament bulbs are available in Europe, I am not aware of any in the US. The market for the filament bulbs inthe US is quite immature. If they do get popular, there may be motivation for selling high CRI models to comply with the California title 24 recommendations:

CRI >= 90

R9 > 50

CCT 2700-3000k

Colour consistency within 4-step MacAdam Ellipse

No visual flicker

EnergyStar

Response to Aaron's comment #12

Great article. I found it very informative and useful. I'd just like to emphasize what you said in the article text, and clarify your statement in comment #12: "Whether or not these bulbs are cost effective over conventional bulbs just on the face of their specs (averaging 40% more efficiency for 20% more $) is another question". As your article text makes clear, the 40% and 20% figures are in comparison to "conventional LED bulbs", if that means anything, rather than conventional tungsten incandescent bulbs.

While I think the 40% efficiency improvement of these bulbs is a great step forward, it's also worth keeping in mind their incredible improvement over conventional tungsten incandescent bulbs, which are still widely sold. At 127.1 lumens per Watt, the best of these bulbs offers a slightly better than 1,000% efficiency improvement over the 12.6 lumens per Watt given by Wikipedia as the norm for a 40W tungsten incandescent bulb.

Log in or create an account to post a comment.

Sign up Log in