Josh Mayfield has extensive remodeling experience and a Habitat for Humanity project under his belt, but he has yet to build a house on his own. The project he has in mind, a few years down the road, will start with a wood foundation.

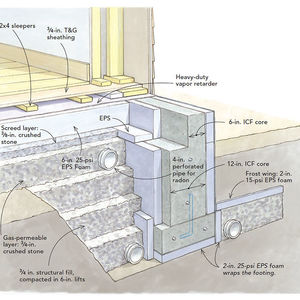

In a recent Q&A post, Mayfield lays out the basics for this detached accessory dwelling unit (ADU) to be built in climate zone 3A. The gently sloped site is rich in Carolina clay, where Mayfield identifies water, termites, and radon as major concerns. He intends to either install a dehumidifier in the crawlspace or make it a conditioned space; he also plans on adding a vented radon system.

Permanent wood foundations (PWFs) have a long history in the U.S. but have never given concrete serious competition. With efforts to cut embodied carbon in buildings getting greater attention, more builders may find themselves considering wood foundations. Mayfield, in fact, is taking his cue from a presentation on wood foundations given last year by Mike Guertin, a Rhode Island builder and contributor to both Fine Homebuilding magazine and GBA.

“I’m aiming for near-Passive [House] performance,” Mayfield writes, “but not currently planning on getting it certified.”

Is Mayfield on the right track, or is he looking for problems? That’s the topic for this Q&A Spotlight.

Wood foundation is not a good idea

“I’ll start by saying I am at least 100% against wood foundations, probably even more than that,” says Zephyr7. “This is not the place to skimp in any way. This is really a place you want to use masonry as any issue with a failing foundation in the future is going to be a major expense.”

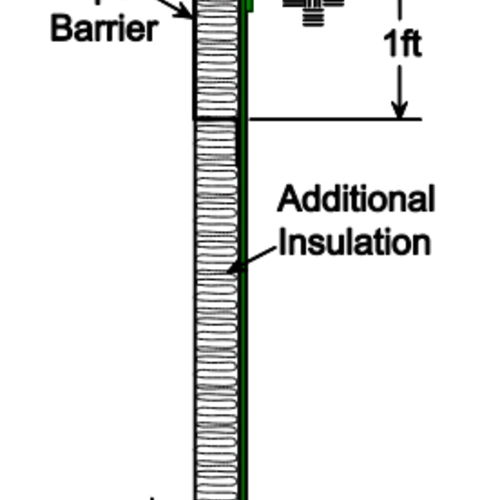

Because much of the house will be above grade, as shown in the drawings…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

7 Comments

GBA's keyword matching system recommends, as a related article,

https://www.greenbuildingadvisor.com/article/all-about-helical-piles

I think that's a good way to get the low carbon footprint while avoiding many of the challenges discussed here.

Having a crawl space at the outset just seems like a good idea, and I would advise straight-up doing whatever it took to have one. To avoid the bottom of the wall kicking in you don't need a floor or slab there, you can simply bury part of the foundation wall in the ground surrounded by gravel fill. It's a little more wood that goes in the ground, but you buy yourself a future-proof service space, and that is usually worth it IMO. If "bury the wood in the ground" sounds anathema, remember that these assemblies are using treated wood (UC-4B) that you cannot even get at the box shops. This stuff is insane; they make docks and piers out of these treated products -- in salt water (UC-5). Soil-contact -- with proper water management and attention to detail -- is easy duty in comparison.

This brings up an important topic. Concerns about PWF are usually born of ignorance regarding the methodology, pure and simple. Yeah sure everyone has a story, but so far these assemblies are looking really good in the aggregate. But you make them a particular way, with very specific materials, and not in any other random or money-saving way. For example, PWFs are supposed to be dry, period. The prescriptive approaches always make a big deal out of water management, same as with nearly any other type of basement or foundation you would want to last 100 years. The required preservative treatments for PWF construction essentially eliminate issues with insects and rot. If you don't want to believe that, then believe whatever you like, but the AWPA has a room full of building materials scientists who would like to have a word with you. There is another consideration that we need to take very seriously -- that the near future is probably not our friend here. The manufacturing of concrete is the third-largest single contributor to global greenhouse gas emissions, at 8% globally, even beating out the airline industry. If you don't think GHG emissions are a problem for you personally, then good for you. However, the current administration has recently signed back onto the Paris Climate Accords, and the president has stated (backed by major corporations and the Pentagon) that he intends to work the US economy toward a 50% reduction in CO2 emissions by 2030. If you think that's bunk, then good for you. I suggest you might want to take a more strategic position and recognize that CO2 emissions from cooking lime -- being a dirty industrial process favorable to regulation -- may come under intense examination, such that some less-than-strategic uses of cement might, in turn, be curtailed or heavily regulated in the near term. Say, for example, cement used in residential construction when there are proven ways to accomplish the same thing without cement. If it comes down to reducing the use of cement in home construction versus reducing commute miles for suburban families, guess who gets reduced firstest the mostest. It may be time for builders to start looking at all-wood ways to build their homes. Has nothing to do with being Green or woke or progressive or anything else, it has to do with good business in a changing world. And who knows, maybe pointing out to a buyer that a home is all-wood, with a minimal initial emissions footprint, could even become a major selling point in the future. Sort of like how having solar panels installed already is a big bonus. Or having a Level 2 EV charging station already installed in the garage. Or having 2x6 walls with extra insulation. Or say going with mini-split heat exchangers and zoned heating/cooling. Resistance to these obvious win/win moves looks increasingly self-defeating as the world tries to walk away from profligate energy consumption and GHG emissions. One's personal or political inclinations in regards all this matter little in the marketplace of ideas, you see. Right now we need a lot of new ideas, and quickly.

I agree. Political inclinations don't have to be what inform these decisions. The world economy is g0ing in a pretty clear direction, and it doesn't really care whether you agree with it 0r not. It doesn't pay to be like the people who decided to stick with horses and sailing ships at the beginning of the 20th century because they liked them more than internal combustion engines. History was against them.

Nope, nope, and more nope.

Absolutely not the place to try and skimp.

All the 30+ year old ones used as examples had a different treatment process, than what you can buy now, invalidating them as examples of how long a new one may last.

It seems that most the commenters are ignoring the termite issue as well... If it wasn't for termites ICF is easy and novice friendly, but the foam gives them an easy access to the building, as would exterior mineral wool.

Besides with current pricing pwf might cost as much concrete. Around here the cheapest low grade pt plywood is $75 a sheet, and concrete is $125/yd.

The excavation costs are the same, but pwf is going to require more stone for drainage, and a lot more work to get the stone properly compacted, and level.

The lumber treatment most often used for PWFs even now is the same as it was 20, 30 and 40 years ago - 0.60 CCA . I agree that standard UC4A Ground Contact CA, ACQ, MCQ and other treatments aren't suitable for PWFs and should not be used.

And yes, currently costs for lumber change the economics of building PWFs - the same can be said for wood-frame construction in general.

Mike, in your detail, there is no structural 'tie' or bracing between the all the tops of the PWF walls. I know there is very minimal difference of fill on either side of each PWF wall, but would there be any concern of lateral soil forces pushing inward causing the subfloor to buckle? Or would you think these wouldn't move once back-filled properly?

Reason I ask is because I am considering something like this. I've drawn it in Sketchup and it got me worried that the PWF stem/frost walls could be moved away or toward each other. So I added the 2x4 joist/sleeper floor prescribed in the SPC PWF manual that is supposed to be at the bottom of the PWF walls for crawl space or basement floor for bracing; but I moved it UP above the foam and below the subfloor.

Any thoughts as to if you'd think this would be needed?

Where can I find the original Q&A thread? I am in the same situation as Mayfield - trying to design a PWF and wondering if I'm getting all the details correct. I've done a bunch of research, and watched the BS+Beer episode from last October, as well as all of the awesome content linked in that article. Some differences between his project and mine: I'm in zone 4c, and I have a walkout basement so half the basement is almost entirely below grade and the opposite side is basically a frost-free shallow foundation.

One of the questions I have about this article is that I see in the drawing that the Henry Blueskin is on the outside of the foam. When would you want it over the foam vs under (against the plywood sheathing)? I would expect the foam to help act like a protective shield since this is the water barrier.

Additionally, would the use of geofoam/EPS for a footing over the compacted gravel as a base for the 2x12 footing plate eliminate any concerns of flexing? Would it provide any real insulation benefit? How does that benefit/lack thereof change by depth (e.g. 4' down vs 1' down)?

Thanks!

Edit: Of course, after I comment I find the original thread.

Log in or become a member to post a comment.

Sign up Log in