Image Credit: Energy Vanguard

Image Credit: Energy Vanguard Peeling paint on some of the earliest insulated houses led us down the misguided path of thinking that interior vapor barriers were the answer to many moisture problems.

Image Credit: Energy Vanguard

Is housewrap a vapor barrier? What’s the purpose of building paper? Who’ll stop the rain? I’ve covered this topic in various forms before, but the confusion about what the different building materials do is so widespread that I have to keep coming back to it.

I’m going to keep it simple here so maybe we can get a few more people to use the proper terms, and especially to know when to use the term “vapor barrier” … and when not to use it.

Vocabulary, again

First of all, remember that the purpose of the building enclosure is to control the flows of water (liquid and vapor), air, and heat. We use different materials in buildings to accomplish the various levels of control we need, and of course, what you need in your building depends on your climate and what you’re doing inside.

The term I like best to describe these materials is “control layers.” There’s a liquid water control layer, a water vapor control layer, an air control layer, and a thermal control layer. That term helps unify the group.

They also have different names. As I wrote in a recent article on controlling liquid water, the liquid water control layer is also called the drainage plane or the water-resistive barrier (WRB). The water vapor control layer is also called a vapor retarder or vapor barrier. The air control layer is also called an air barrier. The thermal control layer is also called insulation. Those terms probably aren’t going away anytime soon.

Did you really mean to say “vapor barrier”?

The biggest point of confusion seems to be about what a vapor barrier is. Most often, I hear people saying they need a vapor barrier when what they really mean is they need a liquid water control layer.

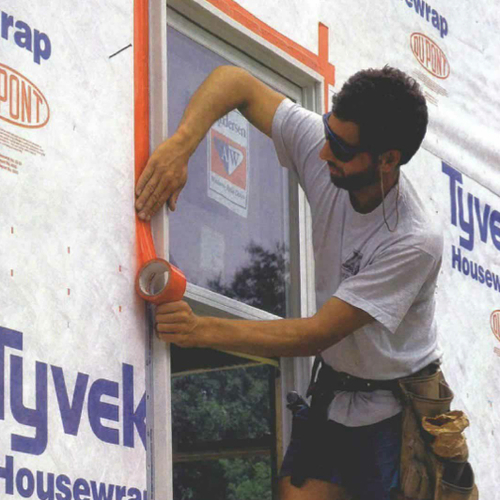

Housewrap, to answer the question I opened with, is not generally a vapor barrier. Dupont’s Tyvek Homewrap has a permeance of 58, putting it way into the vapor permeable range.

As I wrote not that long ago, it’s generally more important for building assemblies to be able to dry out than it is to stop water vapor from moving into them. We got on the wrong track with vapor barriers in the mid-twentieth century because of some incomplete science.

The two kinds of insulation

Another one I hear quite a bit is the confusion about what insulation does. Insulation comes in both air-permeable (like fiberglass or cellulose) and air-impermeable (like spray foam) forms. Putting in more fiberglass or cellulose insulation won’t give you the airtightness you need in a house without additional air-sealing.

These fluffy insulation materials are thermal control layers but not air control layers. Spray foam insulation of the proper thickness is both.

One material, multiple levels of control

Housewrap, to stick with the most common material used as the liquid water control layer, is a material that can control the flow of liquid water as well as air. It’s rarely installed well enough to be a good air barrier, but that’s OK because in most homes it’s stapled to a material that usually is: plywood or OSB. Housewrap is the material. Controlling liquid water and air are the functions. The standard varieties don’t control water vapor or heat.

Open-cell spray foam can control heat and air but not water vapor or liquid water. Closed-cell foam can control heat, air, water vapor, and liquid water. Rigid foam insulation, depending on type and facings, also can control all four.

When you’re looking at plans or actual building assemblies, go through material by material, layer by layer, and see if you can identify the functions of each. Is that material controlling heat, air, liquid water, or water vapor? Is it controlling more than one? Even if it’s there for structural reasons, you need to know how it might affect the flows of heat, air, and moisture. OSB, for example, is vapor semi-permeable and can reduce an assembly’s ability to dry.

Getting the building enclosure right is critical to the success of a building. Knowing this stuff is the key to getting the building enclosure right.

Allison Bailes of Decatur, Georgia, is a speaker, writer, energy consultant, RESNET-certified trainer, and the author of the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

10 Comments

Moisture within the wall assembly

Great article, thank you

My inquiry concerns the walls ability to dry.

With the increasing use of exterior rigid foam or closed cell spray foams which effectively are air/vapour barriers, will applying a poly on the warm side of the assembly trap the wall moisture within the wall?

The poly should prevent further moist air from migrating in but the lumber may still have not dried out sufficiently before the poly is applied.

With the reality that moisture in my wall may reach it's dew point (here in Canada), if I don't apply a poly on the warm side will the moisture be able to dry sufficiently though the drywall if I use a high vapour permeance paint.

Sent from my iPad

Response to Marc Ouimet

Marc,

If you install closed-cell spray foam between your studs or rigid foam on the exterior side of your wall sheathing, you definitely don't want to install any interior polyethylene. For more information on this issue, see Calculating the Minimum Thickness of Rigid Foam Sheathing.

The type & permeance of the foam matters

Most sprayed closed cell foam and XPS hit about 1 perm at R6, which is the high-end of the Class-II vapor retarder category, and still has plenty of capacity for releasing the moisture from the lumber or damp sprayed cellulose to the exterior. But at R20, forget about it- it could take years!

Rigid foam with foil facers are as vapor retardent as the poly vapor barrier, forget about that too.

Type-II EPS doesn't hit the 1-perm mark until about R12.5 (3"), and Type-I EPS (1lb per cubic foot density) doesn't get there until about R20. Even at 4" (R16.8) Type II EPS is 50% more vapor permeable than kraft facers on batts, and if the siding is rainscreened to limit moisture drives form the exterior, still has plenty of drying capacity.

Closed cell spray foam

Allison, you mention closed cell spray foams (ccSPF) ability to act as all four control layers. I understand that in theory ccSPF can stop liquid water, water vapor, air and heat. I don't see how you could implement it so that it actually performs that way in a real building envelope.

Specifically, how would one use ccSPF as a liquid water control layer? When I see application photos in wall cavities, they all show a pretty irregular surfaces after it has cured. Wouldn't this irregular surface cause practical concerns? Possibly allowing spots on the wall (or roof) where the surface features allow liquid water to "perch" and collect in small pools. I'm sure ccSPF can repel liquid water when the contact is intermittent and relatively short in duration, but can you make a bowl of ccSPF that holds water for hours/days?

I mostly ask this as I often see people on this forum, and other, treat spray foam as a panacea (users, not editors). If they have a hard time thinking about an application issue, they jump to spray foam. If there is a practical issue with using ccSPF as a liquid water control layer should it really be described as performing as one?

P.S. Hope you're staying warm there in Atlanta, news shows quiet a few people without power down there.

Response to Daniel Young

Daniel,

Q. "Specifically, how would one use ccSPF as a liquid water control layer?"

A. Closed-cell spray polyurethane foam is routinely used for roofing. For more information, see these two articles:

Spraying Polyurethane Foam Over an Existing Roof

Roofing With Foam

Roofing with foam

Thanks for the links Martin. I think I had an exaggerated image in my mind on the extent of the rough surface left after a spray foam job. I would imagine care is needed to get a surface as smooth as shown in the first article, but obviously it is achievable.

My personal choice would be to use a dedicated WRB, rather than rely on spray foam. But that's just me. I would personally avoid spray foam in general though, so I'm bias.

DP Cellulose?

For some reason my favorite insulation material always gets short shrift, even in green building circles. To my mind dense pack cellulose has all the advantages: no health concerns for installers or occupants, very low embodied energy, discouragement of rodents and insects, resistance to fire, a long history of successful use, and it works in retrofits and new construction. And yet in conversations like this one it somehow ends up off the radar. You say:

"Putting in more fiberglass or cellulose insulation won't give you the airtightness you need in a house without additional air-sealing."

A dense pack cellulose wall or ceiling stops air infiltration as well or better than any other material we use. To continue your analysis: It will certainly want the WRB to protect it from bulk moisture, but it won't care about a vapor barrier since it is hygroscopic and behaves much like wood does. If it's "generally more important for building assemblies to be able to dry out than it is to stop water vapor from moving into them" then I'd think DPcellulose would be at the top of the list.

Why the weird bias? There are lots of factors here, but I'd guess probably a lot of this is driven not by building science but by marketing: Put Dow's spending on advertising, consulting fees (don't be dense--Dr. Joe brags he is on the payroll), and project sponsorship (...so many DER foam case studies for some reason) next to what National Fiber can muster and you get the idea.

Response to Bennett Sandler

Bennett,

I'm not sure why you are so sensitive on this issue. Speaking for myself (not Allison, who is probably experiencing a snowstorm and a power outage now), I always tell readers that cellulose insulation should be their first choice for insulating the stud cavities of existing homes with uninsulated walls, and it should also be their first choice for insulating attic floors. GBA has been promoting cellulose for years.

A cursory reading of my product reviews will reveal that I don't go out of my way to make DuPont and Dow happy.

GBA has accurately reported, for years, that cellulose insulation will significantly reduce the rate of air leakage through uninsulated walls, but that it isn't an air barrier.

I agree with you Bennett

Some items natural more green items are mentioned here and there but often are afterthoughts... aside mentions...

Having decades of experience and reading online about green... I have mentioned more than once that GBA lost a passionate natural green advocate a few years back and that GBA could be well served by having a natural green tab dedicated to less chemicals and more cut from nature.... cellulose, logs, hay bales, rammed earth... of course there are no corporate producers of hay or logs the size of Certainteed or Dow.

And yes GBA has a green as one can get leader in Martin and we all very much appreciate him and this site.

Just would be nice to see a natural green tab.

@ martin...

Sorry, Martin--didn't mean to offend or to hijack the topic, and I don't mean to grind an ax. In fact I owe you a lot more than I can say, and I hope I can thank you in person some day. GBA is consistently a fantastic source of information about what we do.

The idea that money talks is pretty obvious, though. And the idea that it could be biasing the science and public perception here, like it does in other places, should not be particularly controversial I think. I would guess the fact that Allison doesn't mention dense pack cellulose is a simple oversight. I am not offended, but I am curious why there seems to be a pattern. Foam is always the default and dp cellulose is the bastard stepchild. BSC dismisses it but doesn't seem to want to study it, WUFI's got gaps in the data set so it can't model it properly, there seem to be few long term case studies, etc. etc. I hope it's not out of line or hypersensitive to notice that this larger conversation about insulation is going to be heavily influenced by the marketing muscle of chemical companies.

Re the terminology, dense pack cellulose is obviously not an "air barrier" or an "impermeable" material. But it's also not necessarily "air permeable" the way Allison classifies cellulose either. What do we call it then? Is it an "air control layer" in his scheme?

Log in or create an account to post a comment.

Sign up Log in