By now, most of us working in the green-building industry know what a blower door is. It’s a tool to measure the air tightness of a house. I’ve owned my Minneapolis Blower Door since 2009. Many states have adopted mandatory tightness testing on all new construction. In my area—Grand Rapids, Minn.—the minimum is three air changes per hour at 50 Pascals (3ACH50), most new homes I test are around 2ACH50. Test results for existing homes vary widely. Some would pass today’s requirements, while others I have tested were as high as 20ACH50. Finding air leaks in these older homes can take some work. Combine a blower door with a thermal imaging camera, along with a few degrees temperature difference between inside and outside, and most air leaks become visible. When “seeing” air leaks isn’t possible, I perform zonal-pressure testing.

What is zonal-pressure testing?

Zonal testing is the process of testing an area in a house to see if the space has a connection to the outside. Instead of looking for an individual air leak, the test checks a space or a room for all air leakage in the designated area. This speeds up the process for finding air leaks by pinpointing the rooms or areas with the biggest issues. To conduct a zonal-pressure test, the space being tested must be isolated from the rest of the house by closing a door. Other areas that can be tested are attics or crawlspaces, which are supposed to be outside the building envelope.

It’s important to note that this type of testing does not give an actual air-leakage rate. Instead, the information yielded is a relationship between the area where the blower door is operating and the space being tested (more on that later). First, let’s go over how I perform the test; there are two methods.

First method: cruise control

The house is set up for a typical blower-door test—all interior doors are open, windows and exterior doors are closed and locked, and HVAC/other exhausting equipment is off. Additionally, make sure any wood-burning appliances are completely out and the ash is removed or covered.

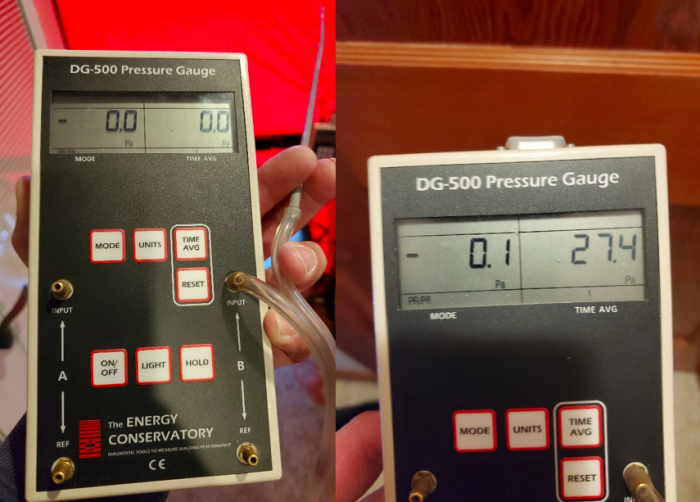

The test is conducted by setting the blower door to operate at a steady state, typically -50 Pascals, often called cruise control. I use a DG700 pressure gauge, a laptop, and Tectite software to control my Minneapolis Blower Door. Once the pressure is set, I use a second manometer—a DG500—to measure zonal pressures. The DG500 has four ports to attach hoses. I attach one hose to the “B” input channel, while the “A” channel is used as reference for the room in which the manometer is located—typically that is outside the area being tested. The hose is then placed in the room being tested. I am comparing the pressure of channel A with the pressure of channel B.

The blower door is operating at a steady -50 Pascals. This pressure difference is between inside and outside the home. Because I am inside the home, I expect every room located inside the air-control layer to be at -50 Pascals in relationship to the outside. This test measures pressures between spaces located inside the building’s air-control layer, which means the pressure difference between these inside spaces should be equal. The readings on both channels of my DG500 should be 0.

If I test a room by placing the hose inside and closing the door, I expect a reading of 0 on both channels of the manometer, meaning I have no connection with the outside. Most of the time, I have some difference. This difference can range from .1 to 50. At .1, the room is nearly the same pressure as the space outside the room—meaning it is well air-sealed. A reading of 50 means the room is completely outside the air-control layer, and there are a lot of air leaks to identify. A reading of 25 indicates the room is half connected to the home and half connected to the outside—a 50/50 split.

Interpreting the results of first method

With the blower door operating at 50 Pascals, this relationship between spaces inside the home can easily be converted to a percentage. A 50 Pascal reading on my DG500 would make the room 100% outside the air-control layer; 25 Pascals is 50% outside the air-control layer; and 5 Pascals is 10% outside the air-control layer—that’s a 2:1 ratio. The photo above shows the results from an actual test. The bedroom being tested is the upper level of a story-and-a-half design built in 1952. There are attic knee walls where there is no definite air-control layer, and it shows. The DG500 is reading 27.4 Pascals. This room was 55% connected to the outside. This bedroom is a good candidate for air-sealing measures.

Second method: measuring outside the air-control layer

Another way I conduct this test is to compare spaces that should be completely outside the air-control—spaces like unconditioned attics, unconditioned crawlspaces, or attached garages should be 100% outside the building envelope.

Trying to get a floppy hose into these spaces doesn’t work well, so in my blower-door kit, I have a 12-in. piece of 1/8-in. metal tubing that I use to test spaces that are hard to access, which is pretty much any space that doesn’t have a door to close. This metal tube can be attached to the plastic hose by drilling a small hole and inserting the rigid metal tube.

Here, I am measuring pressure differences between inside and outside the air-control layer. I expect a difference of 50 on my DG500. If I get another reading, I know I have some connection with the inside of the home.

Interpreting the results of second method

When conducting zonal-pressure testing, I almost always read some difference between the space being tested and the area outside that space. I look for readings on my DG500 of at least 5 before I investigate the room further. This means I have up to 10% connection with the outside with the house at a pressure of 50 Pascals—a much higher pressure than the house will see under normal conditions. The natural air leakage will be something less.

Another type of test

It is also possible to conduct an HVAC zonal-pressure test using my DG500. This test is done with the blower door off and a forced-air furnace operating. In this case, I am determining if the forced-air system is pressurizing or depressurizing a room or space in the home. Forced-air systems need to be balanced, meaning the supply and return are equal. In my heating-dominated climate, a room that becomes pressurized during normal furnace operation can push warm air into the wall or ceiling cavities, at which point the air can find a condensing surface. The moisture in the air will most likely change from a liquid to a solid and continue to accumulate over the course of the winter. Warmer temperatures in the spring will change the frozen moisture back to liquid. Water damage, mold, and rot can be the result. A room that becomes negative can cause cold air to be drawn in from the outside, resulting in comfort issues.

This test is performed by attaching the hose to the manometer and placing it inside the room being tested. The door is closed and the pressure read. The main difference between the HVAC zonal test and the blower-door zonal test is that the reading of the HVAC test is the actual pressure—positive or negative—of the room, displayed in Pascals. Here, I want to see reading of less than 3 Pascals—more than that would require undercutting the door or adding a jump duct to reduce the pressures inside the room.

_________________________________________________________________________

– Randy Williams is an a residential energy auditor and builder in Grand Rapids, Minnesota. Photos courtesy of the author.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

6 Comments

As you say, you are measuring the ratio of room leakage to the exterior to room leakage to the rest of the house. The latter can be highly variable, which makes it difficult to come to any conclusions about the absolute amount of room leakage to the exterior. 4 pascals with a large door undercut means much more exterior leakage than 8 pascals with a tight interior door.

> I want to see reading of less than 3 Pascals

This is a common number, but is there good data to support it? Given that it might take only a few seconds to adjust a register, why not 1 Pascal?

To me Jon, it depends on the house. If I'm testing an old house with lots of air leaks, I'm trying to determine where air sealing makes the most sense, but if it's new and I'm looking for any leak, yep, 2-3 or less might be the number I start checking. The most commonly used phrase in building science, "it depends."

Door undercuts or jump ducts can have some effect. I look at this test as a quick starting point for more investigation. Do I spend more time with a pressure pan, smoke generator or thermal imaging camera or move to the next room?

Hello, the "Spelling Gestapo" is here. The correct spelling is "manometer" whereas "monometer" is a term you might use to describe certain types of poetry.

I had the same thought as Jon R, that the door being closed to isolate the room can be a big factor depending on whether it fits tight or has a large gap below where air can easily pass. So this approach is essentially one that roughly verifies whether things appear to be in the right ballpark or whether a closer look might be a good idea.

I've never used a DG-700 but I'm wondering if rather than comparing A and B to get the pressure difference, couldn't you just use one channel where the hose is attached to the INPUT and REF is automatically the pressure of the room where the manometer is located? I suppose there is "more than one way to skin a cat"

Yeah the use of two channels here confused me too. Channel A, with both ports just open, isn't measuring anything other than the noise in the sensors. There is no pressure difference (of any relevant level) within an airspace like a room and it's not related to the pressure difference between rooms/spaces.

Dennis,

Thanks for your comment. You're right about the spelling, of course. I've corrected the errors.

I am a new EA and I would like to have the capability to do zonal testing like this. I'm looking at different manometers and I wanted to ask, does it need to be a 2 channel unit or would a single channel unit suffice? Does any one have any recommendations for an entry level unit I could pick up to start learning?

Log in or create an account to post a comment.

Sign up Log in