With a basement remodel underway, Jeff Dieterle weighs his options for a trouble-free floor. “We want to do the kitchen and bathroom in tile or stone and the rest of the area in wall-to-wall carpet,” he writes in a Q&A post at Green Building Advisor.

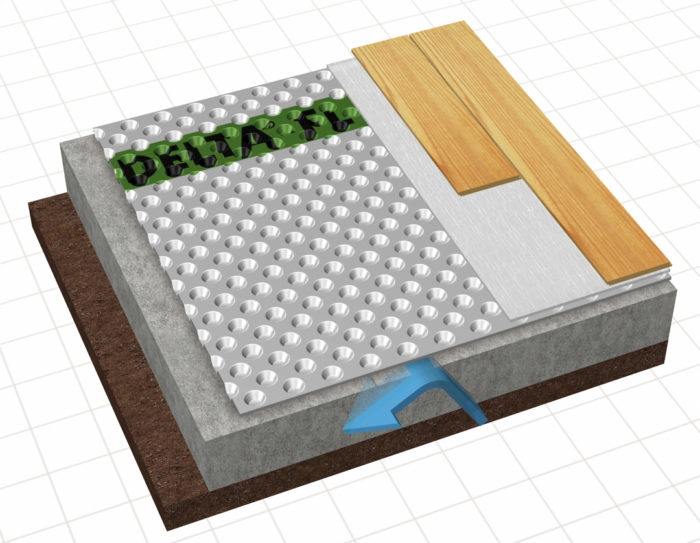

So far, he’s found two products that would seem to work: Ditra-Heat under the tile or stone sections of flooring, and a product called Delta FL in tandem with tongue-and-groove plywood under carpeted sections.

Dieterle has never had a bulk water problem in the basement in the 17 years he’s lived in the house. Even so, he’s not sure that the Delta membrane/plywood combination is a good idea.

“Not fond of the T&G plywood in the basement as everything else will be mold-proof,” he writes. “Are there other options beside inorganic individual tiles? Or is the Delta FL system reliable?”

That question is the start of this Q&A Spotlight.

Two potential water problems, not just one

There are two types of potential water problems in a basement, GBA Senior Editor Martin Holladay says. One is the possibility of water leaking in from the outside; the second is that a cool concrete slab can become a condensing surface for moisture, particularly in the summer. The first is apparently not a problem here.

“In general,” Holladay adds, “you don’t ever want to install carpeting on a concrete slab unless you are sure that there is a layer of horizontal rigid foam under the slab. (The foam insulation keeps the slab near the interior air temperature, greatly reducing the chance of condensation.) Without the foam insulation layer, you can get moisture build-up and mold under the carpet.”

Most older houses don’t have a layer of foam beneath the…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

90 Comments

What would you recommend for flooring in suburbs of Atlanta?

This forum is right on time. I'm in the process of finishing my basement. I will have 2br, a family room and bathroom. I was thinking about doing carpet in those areas, (mostly comfort for kids) but with an underlying system like rigid foam, and then ??? I don't mind doing tiles, which is water proof right? I don't ever have to change if I get a leak? What sought of tile outs be best?

What is the process for this? I'm putting up rigid foam ( 3/4 rigid foam sheathing , bc studs already up, can't find 1" and don't have enough space for the 2" on basement wall.

Thanks..

I'm enjoying all the education from this website.

Response to Nat Hilton

Nat,

If your basement slab lacks sub-slab insulation, you’ll need to install some rigid foam above your slab -- especially if you decide to install carpeting. Otherwise, the slab or the flooring will be damp during the summer (due to condensation on the cool slab).

The usual technique is to install 1 or 2 inches of XPS or EPS foam insulation on top of the existing concrete, followed by a layer of plywood that is fastened through the foam to the concrete with TapCon fasteners. (If you are still worried that your slab may sometimes be damp, you might want to install a layer of dimple mat under the foam.) When installing this layer of foam, it's important to make the installation as airtight as possible, to make it impossible for any humid interior air to contact the concrete. Seal the edges of each piece of foam insulation with a high-quality European tape, with caulk, or with canned spray foam.

If you don’t want to lose the height required for rigid foam, you could try installing a dimpled subfloor product like Delta-FL. (Note that some similar products, notably DRIcore, have mixed reviews from some builders. For more information on this topic, see comment #6 from Mike Guertin, below.)

For more information on insulating existing basement slabs, see:

Finishing a Basement Floor;

Green Basement Renovation; or

The Stay-Dry, No-Mold Finished Basement.

Any chance someone could post

Any chance someone could post a link or two for the washer switch stated above? Methinks this is something I need to do.

Response to Dennis Brown

Dennis,

It's a valve, not a switch. The classic valve has been manufactured by Watts Valves for decades -- the good old Watts #2.

Here is a link to a page from a retailer:

http://www.amazon.com/Watts-Brass-Tubular-2-M2-Valve/dp/B00128816E

Here is a link to the item on the Watts website:

http://www.watts.com/pages/_products_details.asp?pid=736

Existing plumbing fixtures and cabinets

I have an existing finished basement that I want to renovate in order to add insulation to walls and floor (currently no floor insulation and carpeted, and walls have batt and poly). My question is in the bathroom, do I lift out the shower, cabinets, toilet, etc. to install the XPS and plywood, then reinstall the fixtures on top (while extending the drains, of course). Are fixtures normally installed over top of this subfloor system?

Thanks

Darcy

Response to Darcy Grant

Darcy,

Q. "In the bathroom, do I lift out the shower, cabinets, toilet, etc. to install the XPS and plywood, then reinstall the fixtures on top?"

A. Yes, that would be the best way to proceed.

Q. "Are fixtures normally installed over top of this subfloor system?"

A. I'm not sure what you mean by "normally," but if you have a bathroom in your basement, and if you want to install rigid foam above the slab and on the interior of your concrete walls, the way you describe is the best way to proceed. It probably wouldn't hurt to support the toilet and bathtub with a few lengths of pressure-treated lumber (installed as sleepers, replacing some of the rigid foam).

dmx 1 step

Has anyone heard about DMX one step? It seems to be similar to Delta-fl, but dmx has an R value and also some antibacterial foam, which they say helps with the clicking noise delta makes. 10mm or more laminate can be installed over this , offer at HD, but needs to be special order. It's also a little pricier..

EPS / XPS foam density

I'm working on a project where we're needing to match an existing floor height. We're dealing with an existing basement in Climate Zone 6. A portion of the basement has already been finished using 1.5" EPS foam and 3/4" plywood. I'm considering using XPS or EPS foam at the same thickness so all of the floor heights match up. I'm comparing prices but I'm unsure of the appropriate density of either material. Does it matter much if we're covering it with 3/4"plywood + flooring anyway?

The EPS seems cheaper, but it won't accept tape as well as XPS for sealing all the seams. Any suggestions?

Response to Mark Fredericks

Mark,

The short answer is that ordinary EPS has sufficient density and compressive strength to work in this application.

To read about a successful use of EPS for this type of job, see Green Basement Renovation.

The same job is also profiled in this article: The Stay-Dry, No-Mold Finished Basement.

best alternative without using rigid foam on the floor

I have a 7yr old house at West Chester, PA, with concrete slab in my unfinished walk-out basement. I don't know whether the builder had put rigid foam under the slab. I am in the planning stage of having the basement finished. What is the best alternative to provide a subfloor for either carpet or laminates without using rigid foam? Any thick subfloor may require redo the stairs for meeting the code. Thanks.

Response to Fred Zheng

Fred,

The correct way to insulate a concrete slab is with rigid foam. If you don't want to use rigid foam, that means that you want to do it the wrong way.

If you intend to finish your basement, and your basement slab lacks sub-slab insulation, you’ll need to install some rigid foam above your slab. Otherwise, the slab will be damp during the summer. (If you aren't sure whether your slab has insulation underneath, you can drill a hole through the concrete to inspect what's under there.)

The usual technique is to install 1 or 2 inches of XPS or EPS foam insulation on top of the existing concrete, followed by a layer of plywood that is fastened through the foam to the concrete with TapCon fasteners. (If you are still worried that your slab may sometimes be damp, you might want to install a layer of dimple mat under the foam.) When installing this layer of foam, it's important to make the installation as airtight as possible, to make it impossible for any humid interior air to contact the concrete. Seal the edges of each piece of foam insulation with a high-quality European tape, with caulk, or with canned spray foam.

If you don’t want to lose the height required for rigid foam, you could try installing a dimpled subfloor product like Delta-FL. (Note that some similar products, notably DRIcore, have mixed reviews from some builders.)

For more information on insulating existing basement slabs, see:

Finishing a Basement Floor;

Green Basement Renovation; or

The Stay-Dry, No-Mold Finished Basement.

Flooring options

I am finishing a basement renovation using the method that you have outlined here and in several other articles. I have 1inch of XPS covered by 2 layers of 1/2 inch exterior rated plywood. I wanted to use bamboo flooring in the main areas of the basement, but I wondered whether underlayment options for bamboo would interfere with the drying principles of this system. Can you suggest how to go about installing bamboo or other engineered wood flooring options that is consistent with the principles of this method? Additionally, I have a small bathroom and an entry area. I am assuming that tile cannot be laid over this flooring, and I don't want to use vinyl, but do you have other suggestions? Thanks

Response to Michael Ashooh

Michael,

If you install rigid foam on top of a slab, you don't want to encourage any moisture flow upward. The intent of the flooring assembly is not to allow the slab to dry upward.

Q. "Can you suggest how to go about installing bamboo or other engineered wood flooring?"

A. Any engineered flooring product must be installed according to the manufacturer's recommendations. Consult the manufacturer if the instructions that came with the product are unclear.

Q. "I am assuming that tile cannot be laid over this flooring."

A. If your subfloor is adequately screwed to the underlying concrete, I see no reason why tile flooring couldn't be installed over the plywood subfloor. But most builders would advise you that it is easier to install the tile directly to the concrete.

Flooring options follow up

Thank you, Mr Holladay for your quick response. I have been a big fan of your work for some time in FH and here. It's a pleasure to be able to ask you some questions about these issues, if you don't mind.

Just a clarification. When you say: "The intent of the flooring assembly is not to allow the slab to dry upward." Do you mean that the intent is to try to prevent the diffusion of vapor from the slab toward the interior? Or that the system is not designed to encourage or facilitate upward drying? I've always understood it to be the later. Or am I missing a significant distinction between drying and vapor transmission? I've understood the system to be designed to allow for the fact that vapor or water molecules will diffuse toward the interior. So, what I hear you saying is that we are not trying to facilitate that process, only account for it. Am I wrong? For instance, I did not include a vapor barrier between the XPS and the concrete, as many suggested, because as I understood this, the XPS allows for diffusion. But if the goal was to prevent diffusion or vapor transmission, then it seems that I should have included such a barrier. Can you help me to understand that better?

I was concerned with both hardwood underlayments and tile would have very low permeability, lower than the XPS anyway, and so trap vapor in the plywood. Now I am starting to think I have misunderstood something.

BTW, a few tiling contractors thought that the XPS would not be rigid enough over time to prevent flexing, which was another concern, but I am very happy to hear that you think I could lay tile over this. Any thoughts on that concern?

Thanks again for your help. I have been wanting to ask you these questions for a long time.

Response to Michael Ashooh

Michael,

The soil under your basement slab will always be damp. So will your slab, unless your builder installed a polyethylene vapor barrier between the dirt and your slab.

The interior of your house will be warm and dry, while the dirt under your slab will always be cool and damp. We don't want to encourage any moisture flow from the damp soil to your dry interior. We don't want any water vapor flow; nor do we want any liquid water flow. What we want is a barrier to separate these zones.

The usual barrier is polyethylene. If polyethylene was installed under your slab, you are all set. If there are reasons to believe that the builder didn't include any polyethylene under your slab -- a very possible situation for older homes -- then you need to install a layer of polyethylene above your slab. Rigid foam is almost as good as polyethylene, because it stops most of the water vapor transmission -- but not quite as much as would polyethylene.

Again, you are looking for a barrier to separate these zones. It makes no sense to encourage the flow of water vapor from the damp soil under your slab to the interior of your house.

Textured XPS in lieu of a dimple mat?

For slabs that might sometimes get damp, could a textured XPS such as Owens Corning Foamular Insul-Drain be used in lieu of a dimple mat? Maybe the drainage would not be as good as a dimple mat, but better than standard smooth XPS? Thanks.

Humid basement

I have a vacation home in the mountains in Alaska. We do not heat it in the winter until we start using it, usually first of March. I have a full basement that has neither foam insulation or vapor barrier under the slab. Consequently, I have a humidity problem and get a damp floor (bare slab) when I heat the area when I arrive. I believe that my problem is 2-fold in that I get vapor coming up through the slab causing the humid condition and condensation on the slab because it is colder than the rest of the room. My plan is to insulate on top of the slab with eps foam and also use Delta-FL plastic subfloor to help stop the moisture that comes through the slab. My questions are: Will this work? and should I put the Delta-FL next to the slab or on top of the foam? I also plan to lay laminate floor on top of the whole system. I would appreciate any help or advise. The slab was poured 6 years ago.

Response to Gary Nussbaumer

Gary,

Assuming that your basement doesn't have a problem with bulk water entry, the standard solution would be to install a layer of polyethylene against the concrete, followed by rigid foam (as thick as you are willing to install), followed by one or two layers of plywood subflooring, followed by your finish flooring.

You can install Delta-FL if you want, but the Delta-FL is optional. Ordinary tongue-and-groove plywood will work fine in this location.

For more information on this topic, see the paragraphs that follow the heading "Insulating an existing basement slab" in this article: Fixing a Wet Basement.

Martin:

Thank you for your

Martin:

Thank you for your quick reply. I appreciate the input. I believe that if I use at least 10mm laminate floor that I can skip the t&g plywood. Your thoughts?

Response to Gary Nussbaumer

Gary,

I have never installed any type of finish flooring directly over foam, so I'm not sure of the answer. One thing's for sure: you have to follow the installation instructions provided by the flooring manufacturer.

So you should direct your question to the technical department of the flooring manufacturer.

How about in a utility room with a floor drain?

Martin, I'm planning to use the floor assembly that you describe over an existing slab (floor leveler, delta dimple mat, 1 inch xps foam, subfloor, floating wooden floor) but I don't know what to do in the the utility room that has an existing floor drain. We are gut renovating the entire basement so the utility room will be completely open for whatever work we want to do, but I can't decide how important it is to 1) insulate the slab in that room and 2) maintain the floor drain. Any advice would be greatly appreciated.

Response to Daniel Hatch

Daniel,

If you want insulation on your utility room floor, I suggest that you install a polystyrene backerboard product like FinPan ProPanel Lightweight Waterproof Backer Board, Schlüter Kerdi-Board, or Wedi Building Board. These insulating backerboards are designed for use with tile. If you go this route, you can hire a tile contractor to install ceramic tile and a floor drain.

This is more work than most homeowners would feel is necessary, however. The easiest way to proceed is to leave the utility room floor uninsulated -- bare concrete with a floor drain.

bare utility rm floor negating some of our insulating efforts?

Thank you for the incredibly fast reply. That all makes good sense. The only thing that I'm trying to wrap my head around is the possibility that the bare concrete floor is negating some of our efforts to super insulate and air seal the house. If the home owners keep the utility room door closed all of the time, is it not really an issue at all?

Also, head height is a concern and I may need to remove one of the layers from the floor assembly. The project is climate zone 7 but for the most part it's very dry and we are installing a full perimeter foundation drain. Would you prioritize keeping the layer of XPS over the delta mat if I have to choose?

Thanks again. I appreciate your help.

Response to Daniel Hatch

Daniel,

Q. "The only thing that I'm trying to wrap my head around is the possibility that the bare concrete floor is negating some of our efforts to super insulate and air seal the house."

A. Yes, it will negate some of your efforts -- because it will act as a thermal bridge allowing heat to bypass the insulation on the rest of the floor. But the effect isn't worth losing sleep over, in my opinion.

Q. "Would you prioritize keeping the layer of XPS over the Delta mat if I have to choose?"

A. Yes.

Basement workshop

Thanks for all the info in both the article and responses, I've read them all with great interest. I'll be refinishing a portion of my walk-out basement as a workshop. The walls are framed, insulated, and finished with 6" tongue and groove pine panels from a partial renovation 15 years ago. The floors are unfinished poured cement with no insulation. Until reading this, I was considering Delta-FL with t&g plywood as the workshop floor. You highly recommend EPS instead. I will be placing several workbenches and at least one machine on a steel stand on this floor. I'm concerned with the compaction of the foam beneath the tools and benches. Would sleepers be recommended between foam sheets for solidity? Is there an advantage to using epoxy on the cement first if placing wood sleepers directly on the cement? Thanks for any advice or input.

Response to Lisa Weber

Lisa,

I don't think that you will have any problems with foam compaction if your are talking about an ordinary basement workbench and a stationary tool like a table saw or a drill press.

Unusual machinery might need to be bolted to the concrete slab, but you'd have to describe the machinery to get more advice.

If you really want rigid foam with a high density, you can contact an EPS manufacturer and order EPS in almost any density you require.

Basement Build-Out Flooring Prep

Hi all! this site is wonderful and I really enjoy reading all your tips! I have a recently poured 4 inch basement slab with a sheet of poly underneath. The home is only a couple of years old and no water intrusion. I have noticed some condensation under plastic bins, etc. when the sit on the concrete floor. Currently, the temp is constantly about 54 and the RH is in the 72-75 range. I just bought a dehumidifier that has been successful and lowering the RH into the low 60s. I live in the Seattle area and would like to know what you suggest for underlayment for the following:

1) I want to lay tile in a bathroom area

2) I would like to install perhaps some sort of vinyl plank flooring in the main room

I have just over 8' of vertical clearance from the concrete to the floor joists above. I am also trying to keep costs down. I am a skilled DIYer, but have not done a basement build out before.

Thank you in advance!

Response to Greg Volland

Greg,

A recently poured slab stays damp for a long time, so it's best to let the slab dry out before installing flooring.

Most flooring manufacturers include installation recommendations; these recommendations are usually posted online. Check out the installation instructions for the flooring materials you are interested in installing.

Re: your response

How long do I need to wait? It was poured June of 2015... Perhaps I phrased my questions poorly. I will certainly follow the install guidelines for the products I choose. I was trying to understand from your perspective what I needed to do to adequately prep the slab for 1) tile and 2) vinyl flooring or some sort of click lock engineered flooring so I don't have to worry about moisture coming up from below or condensation due to the change in temp from the slab to the ambient room temp.

Thanks,

Greg

Response to Greg Volland

Greg,

The answer to your question -- "How long do I need to wait?" -- depends in part on the brand of flooring that you choose, which is why I directed you to the instructions of the manufacturer of the flooring. Different flooring types have different requirements, and most flooring manufacturers include instructions for installing their products over slabs.

Here is a brief description of the usual testing procedure for hardwood flooring:

"A. Polyethylene Film Test

Tape a 2' x 2' square of 6 mil clear polyethylene film flat to the slab, sealing all edges with moisture resistant tape. Suspend a 250-375 watt heat lamp 2' above the plastic film. After 24 hours, check the film - if no condensation or "clouding" develops on the underside of the polyethylene, the test area shall be considered dry enough to test the concrete slab’s relative humidity.

"B. Calcium Chloride Test

Use a prepackaged calcium chloride test (widely available) and follow the manufacturer's instructions. The Calcium Chloride Test measures the quantity of moisture passing through a concrete floor. This measurement is stated as pounds of moisture over a 1,000 sq. ft. area during a 24-hour period. An acceptable level is 4.5 lbs. or less."

Another article notes, "Interestingly, one case study found it took rewetted, mature concrete with a water-cement ratio of 0.07, drying from one side 515 days, to reach 85% internal RH. To reach the same RH level, newly placed concretes with the same water-cement ratio took 184 days when cured for one day, and 258 days when cured for 28 days (four weeks). For purposes, of these various studies, the mature concrete was either fully capillary saturated or saturated to 95 percent. That is, when the drying starts the whole concrete structure is filled with water, or else the whole concrete structure is 95 percent RH."

If you want to delve deeply into this issue, here are some more links:

When is a Concrete Slab Dry Enough?

Are your slabs dry enough for floor coverings?

Moisture in Concrete and Moisture-sensitive Finishes and Coatings

Response to Martin Holladay

Very interesting information! Thank you again. I will try to do some testing to better understand the moisture levels within the basement slab concrete. Do the same requirements apply in terms of moisture passing through the slab if I was to install the EPS + plywood you mentioned earlier in the thread (and finish with carpet or vinyl flooring)? Would using something like the Delta FL help?

What I also find interesting is that I worked for publicly traded new home builder up here for some time and they would routinely put carpet down over basement slabs that were 60-90 days old all the time and never conduct any tests...

I'm going to subscribe to your site as you are extremely knowledgeable and helpful!

Greg

room air vs. slab moisture

An air temp of 54F and an RH of 72-75% corresponds to a dew point of 45-46F. If your deep subsoil temps are below 45F it's possible to get condensation under a box on an otherwise dry slab just from the room air moisture.

http://mb-soft.com/solar/soilmap.gif

When you put even R4 between a slab in a sub-45F subsoil area the susceptible subfloor & flooring will be much closer to the room temp than the subsoil temp, and that problem goes away. If you're intending to use rugs with cushy underlayments the R-value of the rug & underlayment lowers the temp at the subfloor, making it more susceptible to high moisture from the room air, but if you bump it to R6 you'd be fine almost everywhere in the lower 48.

Vinyl flooring on top of the subfloor creates a potential moisture trap, with the moisture susceptible subflooring between the sub-slab poly and the extremely low permeance vinyl. It's safer to use a vapor semi-permeable finish floor, such as ceramic tiles or wood/bamboo etc.

reply to comment by D. Dorsett

If I am understanding correctly, you are suggesting tile directly on top of the concrete slab (once I've confirmed the moisture level and found it to be within range) for an area like the bathroom and for a living space, I should use the EPS + Plywood with some sort of vapor-permeable finish floor (carpet) or wood/bamboo?

If I was to tile the whole space, are you suggesting I do EPS + plywood + cement board then tile? Not saying I'm totally against it, but it seems like a lot of added thickness, time and expense...

Response to Greg Volland

Greg,

There are many benefits to having the layer of rigid foam above the concrete. If this were my house, I would install as much rigid foam as I could, followed by either cement board or plywood, depending on your preferred flooring.

If you take this advice, you don't have to worry about the moisture content of the concrete slab. It's fine to install a second layer of polyethylene on top of the concrete slab. Encapsulating the concrete in two layers of poly won't hurt the concrete.

Response to Martin Holladay

Thank you Martin!

I think I will then go with poly + rigid foam + cement board in the bathroom and finish with tile. In the living area I will either do the same if we choose to tile that area or will shift to poly + rigid foam + plywood if we elect to do carpet or wood. Does it matter much EPS vs, XPS as long as I get enough R value as Dana discussed?

Warm Regards,

Greg

Response to Greg Volland

Greg,

Most green builders try to avoid using XPS because XPS is manufactured with a blowing agent that has a high global warming potential. If possible, try to find buy a relatively dense type of EPS -- one that is smooth rather than one with visible beads.

Response to Martin Holladay

When you say relatively dense, are you referring to the psi of the rigid foam? If so, what sort of psi is acceptable?

Greg

Response to Greg Volland

Greg,

Even Type I EPS (rigid foam with a density of 0.9 pounds per cubic foot and a compressive strength of 13.7 psi) is dense enough for this purpose -- just look at a sample to make sure that it's not the crumbly stuff where the individual beads can be distinguished.

Why 2 Layers of Plywood

Curious as to why the recommended solution has two layers of plywood? Is it simply to bury the head of the tapcons so they can't be felt through the finished floor or is there physics based justification?

Mike G,

In the The Stay-Dry, No-Mold Finished Basement file they say its just for reinforcement/strengthening the joints. So the second layer would overlap the the seams of the first.

So I read through "The Stay-Dry, No-Mold Finished Basement" as well as the above and a few of the linked articles. It seems that some of them recommend a layer of poly between the concrete and the foam board and others do not. I would assume you would want the poly since both EPS and XPS are semipermeable? The reason I assume this is b/c the water would eventually saturate the foam and make its way up to the plywood, which then provides for a surface for mold growth to occur (which may be wrong). If anyone could clarify it would be greatly appreciated. At this point I am planning on tearing up carpet that was installed wrong on my basement floor and replacing with 6 mil poly + 1" EPS foam + 1 sheet of plywood + bamboo.

James,

Neither EPS nor XPS will become saturated in this location, with or without a layer of polyethylene, unless the basement floods. And in most situations, EPS or XPS will be enough of a vapor retarder to eliminate any vapor diffusion worries.

Most modern homes have polyethylene under the slab. If you know that to be the case in your home, you don't need more poly above the slab.

If this is an older home, and you are worried that there may be no poly under the slab, then adding a layer of poly between the slab and the rigid foam is cheap and potentially helpful. It will certainly do no harm, and costs very little, so you might as well install it.

Mr. Holladay,

Thank you for the quick response! My home was built in 1926, and I've been battling poor repair jobs since I bought it. I appreciate the wealth of information on this site and hope to be closing in on all of the corrections.

Vr,

James

Hello Mr. Holladay,

I live in central Minnesota (climate zone 6). My house is a 4 level split, built in 1993. I have a walkout level that is on a concrete slab. It's very dry and there don't appear to be any moisture problems. My house has excellent drainage due to its location and the surrounding landscaping.

My question is this - I'm concerned about headroom and all of the work required to install 1 inch foam (trimming doors, installing new stairs, etc). I would love to save a 1/4 inch and use 3/4 inch foam. So my install would be poly, 3/4 inch foam, plywood. Does that sound sufficient? Most of what I have seen is 1 inch foam, but I've seen several resources indicate 3/4 is enough if you have good drainage and indoor air controls.

Thanks!

Caleb,

People who are remodeling houses make compromises all the time. I understand your concern about headroom. Deciding to install 3/4 inch of rigid foam instead of 1 inch in order to gain a little headroom is a rational choice.

Basement remodel in Climate zone 5.

I will be using 3/4" OSB subfloor over a layer of 6 mil poly and reclaimed 2.5 XPS over the top of 100 year old concrete. If the foam board joints are foamed and taped prior to glued 3/4" tongue and groove osb installation, Q.) does the OSB layer need to be fastened to the concrete or can it float on top?

Thanks for your very informative site, you make our lives easier by not having to redo what we thought was the right thing to do.

My experience is that basements are a magnet for water, even excluding water from outside. Overflowing toilets, pipe leaks, etc. So think about what happens to the OSB with some unexpected water.

John,

When you say "glued 3/4" t&g osb" can you clarify what it is glued to? Are you thinking of gluing the osb to the foam below?

A layer of 6 mil poly with the 2.5 " xps installed over top with all edge foamed and taped. I was hoping to glue the tongue and groove sheets seams together and use a pc of heavy weight sheet metal as a butt joint backer. The osb would just float on top of the floor. This is a proposed subfloor within a 5' tall basement/ crawlspace for dry conditioned storage, following the venting requirements for such a space. Existing concrete basement floor is dry but no poly below. I was going to tape the new poly to the wall and then foam and tape the xps on the floor to the wall. The walls are also covered in reclaimed 2.5" XPS foamed and taped. Stud wall with gypsum to protect wall XPS installed on top of floor foam and OSB.

Q.) Does the OSB need to be fastened to the concrete, can it just float for possible future serviceability and fastener savings and labor.

Q.) Any recommendations for an OSB top coating that would not cause any problems with the described floor system? For the most part a very low traffic in a dry conditioned storage area.

Just very curious, thanks for all input.

John,

Usually, installers choose between one of two approaches:

1. A single layer of plywood or OSB, fastened with long Tapcons through the rigid foam to the concrete below.

2. Two layers of plywood or OSB, installed with staggered seams, screwed to each other (but not screwed to the concrete). This approach avoids "potato chipping."

Martin and all,

Thanks for responses.

Q.) Would either/ both a polyurethane or water based clear floor product applied to luaun plywood be suitable as a finished floor covering over the 3/4 OSB in this insulated basement floor application?

The wood products are over 2.5" reclaimed XPS with a 6 mil poly over top dry concrete floor.

Thanks for all input.

John, my office floor is polyurethaned fir plywood, ripped into 12" strips to resemble a real wood floor. It's ok, but soft--after five years, the finish under my rolling office chair is flaking off, and there are lots of dents. Probably no different than if it was a solid softwood floor, but luann is very soft, and I would be careful about using it as a finished floor. If you do use it, I'd suggest using a drying oil or a spar varnish (or a mix) instead of traditional floor poly.

John,

Whether or not you like the look of polyurethaned luaun plywood as finish flooring is an entirely personal decision.

“[Deleted]”

Understood about shiny sheets of luaun. I was worried about mold etc from an inappropriate floor finishes "sealing in moisture "

I also reread all posts and re-found D. Dorsett's comment :

"Vinyl flooring on top of the subfloor creates a potential moisture trap, with the moisture susceptible subflooring between the sub-slab poly and the extremely low permeance vinyl. It's safer to use a vapor semi-permeable finish floor, such as ceramic tiles or wood/bamboo etc."

I'll look into both options.

Thanks to all.

What are the thoughts on a basement concrete floor finished in epoxy? Clearly not the most comfortable choice, but I see it as being resilient against bulk water infiltration and helping to keep water vapor mitigation down from the slab.

I have never seen a satisfactory finished epoxy floor. Even when the floor is carefully prepared per the manufacturer's specifications, it seems impossible to get a good bond everywhere. If the slab is exposed to moisture, the water vapor can build up enough pressure under the finish to cause it to bubble and flake. Even the newer poured epoxy floors will form large and unsightly bubbles if the slab is ever exposed to moisture.

If the floor is damp, it should be insulated and covered as described in many threads on this site. If it is likely to be subject to flooding, address the water issues first, or leave the exposed concrete and manage the water when it happens.

I've been reading through these very informative comments but none fully addresses our situation. We are finishing a room in the basement and I'd appreciate some advice. We live outside Boston in an 1880 home with a fieldstone foundation, a somewhat uneven poured concrete floor, and 80" to the ceiling joists. Water is not a problem but its a basement so its always possible. Walls will have 3.5" spray foam but the floor is problematic, as we don't feel we can lose more than about 1.5" total for the flooring. We were thinking of Delta-FL - 1/2" foam - 1/2" plywood - floating laminate floor and area rugs. Does that sound reasonable or would you recommend something different?

Four Cats,

Turning the basement of an 1880 home into finished space is always risky. Whether it makes sense depends on your appetite for risk and your budget.

If you need more ceiling height for proper drainage systems, vapor barriers, rigid foam, and flooring, the best solution is to demolish the existing slab and to lower the dirt floor by removing soil. Once you've lowered the floor to the desired height, you can add crushed stone, rigid foam, poly, and a new slab.

Expensive? You bet. But that's the best way to proceed.

If your budget is so tight that you have to cut corners, you need a higher appetite for risk.

If you need another room on your house, you may be happier with an above-grade addition than the risks associated with finishing your basement.

Thanks for your prompt reply. Unfortunately our budget is limited but we need some extra space.

I read in comment #2 and #11 you said "If you don’t want to lose the height required for rigid foam, you could try installing a dimpled subfloor product like Delta-FL." And towards the end of the original article Scott Gibson says "Headroom is an issue, but with as little as 1/2 inch of poly-faced EPS foam insulation plus plywood would sharply reduce the chance of mold growth." So thought since we could afford to loose a little more than the 5/16 of Delta-FL that a combination of Delta-FL and foam would work better than Delta-fl alone, but maybe I misunderstood? Would it be better to just go with 3/4" foam as you mentioned in response #45?

Four,

Your plan is likely to work fine, as long as your basement never has any water entry problems. Of course, thicker insulation would be better -- but your approach will work.

Hi Martin. Is there any flooring product that can go directly over the rigid foam insulation on the floor? I was hoping to use Vinyl plank flooring with just a layer of poly on the floor (headroom concerns), but a response from a previous question leads me to believe this is a bad idea. Thanks in advance for your guidance.

Just started reading this, and unfortunately already put out a sum of money on flooring, of which I can get about 70% if needed. Here goes.

1964 house. Walkout basement. Just purchased. Foundation appears to be in good shape from the outside. Signs of higher end original construction (custom woodwork and probable asbestos tiles!). Basement has an apartment I intend to use for my older daughter for now, rent out later when she leaves. Currently carpeted (orange shag over the probable asbestos, so it all has to go), and feels damp without dehumidifier running (current owner is saving $$), but drywall all around the basement appears to be sound and in good shape. Laundry room has newer tile and feels cold. Limited headroom in apartment area due to ductwork. Location is Madison, WI. Questions: (1) Is there any chance that the basement has a liner or foam underneath it? (2) Would you put blown-in insulation into the basement walls under any circumstances other than the window pockets (West wall has three windows and an exterior door)? (3) Would you consider using a product like DMX Airflow (R-value of 1.9)? (4) If you did use DMX airflow or something similar, would it be ok to use a vinyl floating floor/would the expansion gaps around the product allow enough moisture to be removed by the dehumidifier? (5) If I return the vinyl and we don't like the cork appearance or the wood cost, would laminate breath enough? As you may have guessed, I already bought the vinyl flooring and am deciding whether to eat the $500 restocking fee and the discussion with my wife and go with another product.

“[Deleted]”

Hi Toley.

In my experience and opinion finished basements are high-risk propositions. I've seen expensive finish basements completely ruined when footing drains back up, when sump pumps fails, etc. And I've seen many basement floors installed on the concrete look a mess in no time at all because of unchecked moisture issues. And all of these failures have been in "dry" basements.

I think a layer of EPS rigid foam and a plywood subfloor is money well spent. I'm not sure what Climate Zone you are in, but walkout basement floors tend to be particularly cold near the above grade area of the basement and some insulating value will make the finished spaces more comfortable. EPS and plywood will also allow a bit of inward drying. While the slab doesn't need to dry, this can help prevent materials from developing mold.

If headroom is really that tight, you could consider one of the Dricore products. I believe the dimple-mat product has a 3/4 inch height and the insulated product is an inch in height, which gives you a pretty low profile (but double check those numbers; I could be remembering incorrectly).

“[Deleted]”

+1 on planning for a "dry" basement to get wet. I've seen various water leaks, overflowing toilets, etc. So I have a preference for removable and/or moisture proof materials.

When I become world dictator, finished basements will be banned.

I do hope you make an exception for wine cellars.

Only the ones I've built. There has to be some perks when you are a tyrant.

“[Deleted]”

It's definitely risky to put an impervious flooring directly over concrete. My family has a house with a walk-out basement, built in the 1990s, with good drainage, built on sand. We stained the floor and put a water hog mat at the exterior door. After a few months the stain had failed and there was liquid water under the mat. If we had waited longer it would have been a mold factory. If you are severely limited on headroom, you might consider gluing down a permeable flooring such as cork tiles. But foam insulation is a better choice.

“[Deleted]”

When adding the 1" of eps and 2 layers of .5" plywood (2 inches total before finished flooring) how do you deal with the now reduced height going up your first stair? Thank You!

It may be reasonable to leave the landing not insulated. Maybe just put down tile, if that height can be accommodated. It will be cool, but it is a small area you don't hang out in. If you keep the basement humidity levels in check, you should be fine.

Thanks. But that would seem unusual to me. You would have to step down 2+ inches off the insulated floor, and then back up 8 inches onto the first step?

I didn't say it would be ideal :-) Possibly a trip hazard unless laid out carefully. The low landing might extend out a bit to make it work.

Another way that may work if you have okay headroom is to turn the first step into a landing. This would make sense if your basement stairs come down like mine, about 36" from the wall.

AWilson,

The code only allows a 3/8" difference between the risers on a stair. I don't think there is any legal way around re-building it.

I'm not sure a landing at the bottom would work. Codes generally consider a landing as part of the stair, so it would need the same riser depth.

Depending on how it's built, the easiest way might be to raise the bottom of the stair. That keeps all the risers the same height, and only makes the 13 treads a little over 1/8" out of level.

Would this floor assembly also work for a finished room on the main floor of the house with a sloping, slate-tile-over-slab floor? Efflorescence is common along the one, north-facing exterior wall.

“[Deleted]”

We have a basement slab that has 2" of XPS under it and on the sides, and a Stego-wrap vapor barrier under it. It has also had 13 years for the concrete to dry out since construction. I'm wondering if Delta-FL would be a bad idea, as the concrete couldn't dry in either direction if it were to get wet. Would the DriCor with its ventilated installation (or the Delta-FL, leaving a ventilation gap instead of sealing as instructed) be a better idea? I would like to use engineered wood flooring as the finish material.

@MartinHolladay,

Hi Martin. What would you say is the minimum R-Value needed for a basement floor? There are some underlayment products on the market (lEco Cork Foam) that mention you can put your LVT or LVP right over it. However, the R-Value is about .5. I don't have a lot of height to work with in my basement, so rigid foam and plywood isn't ideal. My house was built in the early 70's so I don't believe there is poly or insulation under the slab. Thanks in advance for your feedback.

More details such as the climate would help. In general, the insulation helps with resisting condensation of the floor, improving comfort and reducing energy use. You can combat condensation with aggressive dehumidication, or maybe your climate doesn't require that anyway. A question to the Q&A section rather than a question at the end of an article might get you help from more people.

Thanks for the suggestion regarding question location Charlie. I am in northern NY, climate zone 5 a. I'm guessing the Eco Cork product will not provide enough R Value due to our temperatures and considering I have a walk out basement.

Your cold ground temperature and high-humidity summers would mean that you would want to dehumidify aggressively to ensure you avoided condensation, and I'd think you'd want something less organic than cork. If you are willing to go to the expense, you can remove the slab, add insulation as thick as you want underneath, and then pour a new slap, or go with a slabless floor design (see a recent story on that) to avoid the CO2 impact of the new concrete. But you might also decide you can live with a lower ceiling height and up the insulation thickness.

Thanks Charlie. Removing the slab, adding insulation "as thick as I want" and then pouring a new slab isn't a helpful solution to what I was asking. I suppose I could demo the entire house and rebuild for that matter. Suggesting that maybe I can decide to live with lower ceiling height seems unnecessary as well. There is a way to answer without being condescending. Feel free to bypass answering questions from me in the future if you can't keep that in check. Regards.

Toley,

I'm not sure how you read any condescension into Charles rely. It seemed like a fairly reasonable outline of what he considered to be your options.

Toley, I'm sorry you didn't find my comments helpful. My goal was to quickly outline the range of options, and inform you about considerations to think about.

Thank you Charlie. I appreciate the clarification.

This has been very helpful, thanks.

I'm trying to use this method in an existing 1965 vintage basement where I'll be removing the ceramic tile. The tile does not go under the existing stud walls with drywall. The stud walls are structural and removing them is not an option. Exterior stud walls have 2" of fibreglas and a vapour barrier. Mold has not been an issue.

The EPS will be installed directly on the concrete floor as described above and butt it up as close to the stud walls as possible. (I'm considering using the DriCore product)

Will this approach exacerbate capillary action through the pre-existing stud walls that are in contact with the concrete floor?

I'm in southern Ontario with a similar climate as the Buffalo New York area.

Evan

Log in or become a member to post a comment.

Sign up Log in