Image Credit: ICC

Significant changes in the energy provisions of the 2009 edition of the International Residential Code (IRC) include air-sealing measures. Section N1102.4, “Air Leakage,” has been completely rewritten to include detailed prescriptive air-sealing measures.

The builder has two options to demonstrate compliance. One is commonly known as a blower-door test, ostensibly be performed by a third party who would issue a report to the builder to pass on to the inspector. The test ensures that air leakage is less than 7 air changes per hour (ACH) with a pressure of 50 pascals (0.007 psi).

The second option is a visual inspection (by an inspector) of several air barrier criteria and insulation. Table N1102.4.2 breaks down what is required for each component:

| Component | Criteria |

|---|---|

| Air barrier and thermal barrier | Exterior thermal envelope insulation for framed walls is installed in substantial contact and continuous alignment with building envelope and air barrier. Breaks or joints in the air barrier are filled or repaired. Air-permeable insulation is not used as a sealing material. |

|

Ceiling/Attic |

Air barrier in any dropped ceiling or soffit is substantially aligned with insulation, and any gaps are sealed. Attic access (except unvented attic), kneewall door, or drop-down stair is sealed. |

|

Walls |

Corners and headers are insulated. Junction of foundation and sill plate is sealed. |

|

Windows and doors |

Space between window and door jambs and framing is sealed. |

| Rim joists | Rim joists are insulated and include an air barrier |

|

Floors (including above garage and cantilevered floors) |

Insulation is installed to maintain permanent contact with underside of subfloor decking. Air barrier is installed at any exposed edge of floor. |

|

Crawl space walls |

Insulation is permanently attached to walls. Exposed earth in unvented crawl spaces is covered with Class I vapor retarder, with overlapping joints taped. |

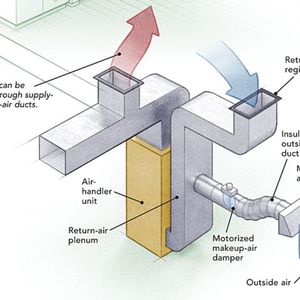

| Shafts, penetrations | Duct shafts, utility penetrations, kneewalls and flue shaft opening to exterior or unconditioned space are sealed. |

|

Narrow cavities |

Batts in narrow cavities are cut to fit, or narrow cavities are filled by spray sprayed/blown insulation. |

|

Garage separation |

Air sealing is provided between the garage and conditioned space. |

| Recessed lighting | Recessed light fixtures are airtight, IC rated and sealed to drywall unless fixtures are in conditioned space. |

| Plumbing and wiring | Insulation is placed between outside and pipes. Batt insulation is cut to fit around wiring, and plumbing or sprayed/blown insulation extends behind piping and wiring. |

|

Shower/tub on exterior wall |

Showers and tubs on exterior walls have insulation and an air barrier separating them from the exterior wall. |

| Electric/phone box on exterior wall | Air barrier extends behind boxes or air-sealed-type boxes are installed. |

| Common wall | Air barrier is installed in common wall between dwelling units (condo or townhomes). |

| HVAC register boots | HVAC register boots that penetrate building envelope are sealed to subfloor or drywall. |

|

Fireplace |

Fireplace walls include air barrier. |

In addition to these measures, this section also adds a few extra requirements:

- New wood-burning fireplaces have gasketed doors and outside combustion air.

- Windows, skylights, and sliding-glass doors have air infiltration rates of no more than .3 cubic feet per minute (CFM).

- Recessed lighting installed in the building thermal envelope must be IC rated and sealed to prevent air leakage.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

2 Comments

Thanks, Lynn

This is important news. Thanks for presenting it in a clear, useful format.

Air Barriers

Thanks for the summary. I'd like to make several comments on the 2009 air sealing requirements. First, 7 ACH50 is an extremely lax requirement and hopefully will be tightened in the near future. I'm assuming this provision's role is to familarize the industry with blower doors. Secondly, we've found that the definition/description of the air barrier in the prescription path needs additional clarification because serious air flow movement often occurs within the insulation cavity. Finally, the effectiveness of the prescriptive path will depend on the quality of inspectors.

Log in or create an account to post a comment.

Sign up Log in