Image Credit: Roger Normand

[Editor’s note: Roger and Lynn Normand are building a [no-glossary]Passivhaus[/no-glossary] in Maine. This is the 23rd article in a series that will follow their project from planning through construction.]

We’ve been at this foundation business for about three weeks now. It seems longer!

After we worked through several snafus detailed in my previous blog, the crew resumed stacking the block. Other chores included:

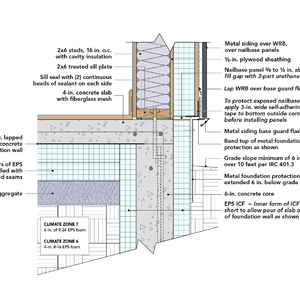

Erecting ICF bracing on the interior side of the block. This steel bracing includes an adjustable turnbuckle to push or pull an errant wall back into plumb. The bracing also served as staging to allow the crew to stack the block to the full 12-foot height of the wall, and later as a platform to control placing the concrete into the block’s hollow core.

Framing a concrete retainer and nailing surface for the four window wells on the south side. We will be using Timbersil rather than pressure-treated lumber where wood meets concrete. PT lumber has associated health and corrosive concerns. Timbersil is a manufactured (and more costly) lumber made by infusing glass into the wood fiber, rendering the wood impervious to rot or decay. It looks identical to dry PT lumber, but the glass barrier in the lumber is permanent, non-toxic, and not corrosive.

Spray foaming any gaps between cut block. While this will seal against air leaks and thermal losses, the more practical goal is to prevent any leaks and potential block failure while placing the concrete.

Nailing temporary horizontal 1-by wood bracing at weak points on the interior and exterior surfaces where less than full-sized block were used, e.g., around window openings, where shorter blocks were needed, or at the two odd angle corners in the foundation.

Finally, we were ready to place some concrete!

When the pump truck arrives, everyone becomes alert

Our Logix block has a 6-inch-thick concrete core. But the horizontal and vertical rebar, plastic zip ties, and plastic webbing in the block present many obstacles to using a mechanical vibrator during the pour. Instead, the crew would bang the ICF walls with hammer and block to vibrate and level the concrete within the block, particularly at the bottom courses.

A trailer-mounted boom concrete pump truck arrived at the appointed hour and set up station, followed by the first of an eventual seven concrete delivery trucks. There was a sense of focus and some tension on the faces of the crew as the concrete began to flow from the delivery truck to the pump truck, up the long boom before emerging from the end of the hose and flowing into the bottom course of block.

Only a few of the crew had experience with ICF block, and none with Logix brand. I guess all “concreters” live with an element of fear that they might have overlooked some detail in the concrete forms, and suddenly there’s a breach letting concrete flow onto the ground. That can be a very expensive repair and even messier cleanup.

Not enough bracing

There were no breaches, and we saw little sign of water seeping out of any joints. Nonetheless, it wasn’t a completely uneventful pour.

We had to await delivery of concrete twice – once because it was being pumped into the Logix faster than deliveries could be made, and then at the end when the crew realized we were short about 4 yards of concrete. Uh-oh. It’s after 5 p.m.

Fortunately, the concrete plant remained open, and quickly dispatched another truck to complete the pour.

Some of the block rose up a bit during the pour but settled back into position as more concrete was added above. It will be interesting to see whether we maintained a uniform elevation at the top of the foundation when it comes time to set the bottom plate of the walls.

A few of the walls bowed out of plumb as we neared the top courses of block. Much of that was because we had 10-foot tall bracing for a 12-foot-high wall. The crew had strung lines at the top corners of the foundation and quickly noticed the problems and brought the offending walls back into plumb.

Convincing the concrete to flow under the windows

It was tricky to get the concrete to flow under the four window openings. The crew tweaked the slump, vibrated from below the window with block and hammer, and above using long poles. The sound from banging the block immediately below the window confirmed the cavity was filled.

In retrospect, perhaps a better way would have been to initially leave out the bottom of the window frame, flow concrete into the cavity until it is filled, then toe-nail the the bottom frame into place.

Overall, we are very pleased the Logix Platinum Series ICFs and the efforts of the foundation crew.

Here’s a video on assembling the block and placing the concrete.

The first article in this series was Kicking the Tires on a Passivhaus Project. Roger Normand’s construction blog is called EdgewaterHaus.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

27 Comments

Foam Concrete Forms

This has always been my concern with ICF, walls out of plumb, out of square and blowouts. In a former life I worked for several commercial firms and we did a lot of pour in place concrete structures. Some forms were Gates but mostly Symons, the Symons system was great for high walls with sort of an integral bracing system as I recall.

So much time and effort will go into making the ICF system workable especially for non standard wall heights. It is really hard to beat wood for ease of construction and versatility later on. The Russian meteor really beat on non resilient concrete structures, something to think about.

Response to Doug McEvers

Doug,

Really? You want to develop a new specification for meteor-proof homes?

one big step behind!

- Filling completely the void under the window bucks is unnecessary in your situation, as the concrete

there servers only as a filler ( until u get a 45degree angle filled up to the bottom corners )

- Where they able to correct the out of plumb tops correctly ??

- What do you mean by " Some of the block rose up a bit during the pour "?

Hope you do not have too much of height variation as it is a PITA to correct with the concrete set.

- What is the rebar spacing in both directions ?

-6" doesn't help much the pouring space... it gets very tight in there with all the fixed stuff

what size of gravel was used in this concrete ?? did your builder tell you what "recipe" of concrete he was ordering ? follow Logix recommandation ?

I found it hard to convince concrete batcher / builders to order the correct concrete..

they usually always go in the "cheaper" direction using way too much water, too large stones

and way to less "super"

- Do you know if Logix have adjusted their pricing from using Neopor EPS or kept their prices the same?

wish you good continuity in your project! :)

Concerns

You may want to temporarily cut out sections of foam at the bottom of the walls, under windows and elsewhere to inspect how complete the pour ended up being. I have heard bad things on another green forum regarding ICF concrete pours WITHOUT internal vibration. In fact one report available online states "Results of the study showed that external mechanical vibration using a hammer, reciprocating saw, or orbital sander did not significantly improve the consolidation of concrete in ICF walls." (http://www.icfmag.com/documents/PCA_Consolidation_Report.pdf).

The need for bracing ICF's

The need for bracing ICF's comes up on forums often, it seems, and there are two camps. The ICF aficionados play it down, and frankly seem a little sensitive/defensive about it. Those not marveled by ICF's seem to be, IMO, more realistic about the drawbacks thereof. I've only poured one house w/ ICF's, and then only 6' walls, and found that the need for bracing, and plenty of it, is real. The dealer supplied us w/ a gackle of bracing, and was quite helpful on the how-to part, but it took a God-awful lot of fussing around to get it right. That is not to say the ICF's are inherently bad, as they certainly have their place in the world. However, some people should be a little more forthright about the potential snags before they advise people, esp first-timers, to build w/ ICF's. I'm w/ Doug M on this; building w/ ICF's is not the cake walk that some folks imply, and from a reasoning standpoint, how could it be easy? Fresh concrete is a liquid, and liquids don't just magically stand erect by themselves. This is from a home-owner's point of view, and an experienced crew w/ lots of bracing may make it look easy. A good brain surgeon does the same thing: Piece of cake; you should try this at home.

concrete voids

Jin Karzana advised:

"- Filling completely the void under the window bucks is unnecessary in your situation, as the concrete

there servers only as a filler ( until u get a 45degree angle filled up to the bottom corners )"

This is dangerous advise.

Contact a civil engineer.

The walls serve a purpose, should be fire proove, should be sound proove and should be statical reliable.

Casted concrete walls with gaps/voids must be demolished, the voids are a sure sign that something went wrong.

The steel reinforcement must be covered by concrete, for external walls in non-agressive environs this is to be at least 1 inch. At least.

In areas prone to water ingress(under the window!) this should be 2 inches. In areas where the environs are agressive (sea-side for example) this should be even more.

PS

That bulging is severe.

More than 2 inches of plasterwork the EPS won't carry, check this out.

Since the concrete must settle in stiff forms ("shuttering") to reach it's strength and avoiding cracks and fissures and capillary gaps this wall is unsafe.

Get a civil engineer in to write a report, contact a lawyer to proceed against those who are responsible.

compacting concrete ....

I just watched the video:

The was no vibrating done, hammering the outside of an EPS (orXPS?) shuttering has nearly no influence on the concrete inside.

Vibrating is done with a vibrator internally, IN the concrete.

Compacting the concrete with stubbs and sticks can be done up to 1 foot of thickness, thicker than that would propably drive-in more air that driving it out.

These weren't professional builders. Funny helmets, funny scafolding ....

The forms (EPS or XPS?) are on the very pale side, there isn't much of graphite in it. Certainly not enough to raise the thermal resistance by 30% .

Such foam would be nearly black.

The cellar/basement is standing in groundwater, was there any detailing spent on making it watertight, esp. at the junction between foundation and platewall, at penetrations? I don't see anything like it on the video.....

Filling gaps below groundwater level with PU foam is calling for leaks.

ICF installer for 9 years

My 2 cents. I am an ICF subcontractor, and have been doing that for nearly 9 years. Even driving is so overwhelming the first few times you do it, that you don't turn on the radio because it is too much to handle. Setting, bracing, and pouring an ICF wall is the same. It gets to the point that it seems much simpler.

That said, it took a lot of years and a lot of mistakes. The manufacturer's recommended bracing procedures were not adequate in my opinion; and we learned by trial and error. More error really. In fact, we still learn something on every pour.

I have found that the only satisfactory method of consolidating the concrete is internal vibration. We us a 1" diameter head on an Oztec. Slump too high and the concrete shrinks excessively and puts so much pressure on the wall that things move too much. Slump too low and you will fight getting things filled even with an internal vibrator.

Nevertheless, it probably isn't something to get your panties in a knot about. There are many post and beam or waffle grid ICF systems out there that have a lot less concrete in them than this wall, even if it is honeycombed.

I am surprised at the animosity toward ICF construction on this site, to the point that most comments are negative. We could also spend a lot of time talking about how things can go wrong with any other type of construction, but we don't; and I am not advocating we do; but why the bias?

I am a strong advocate of professional installation of ICF's. Most of the problems I hear of or that were mentioned in this post and comments are related to inexperience. An inexperienced person can really screw up any type of foundation or above grade wall. That doesn't prove that ICF's are inherently bad.

I would also point out that ICF's are very simple to make non-standard heights, not sure what the meteor proof house guy is talking about. Rip the forms in a table saw, laser the concrete when filled. Done. It may create a bunch of waste, but that is why manufacturers now offer 2" and 4" increments, in addition to half height blocks. Can't be much less work that cutting studs to length!

Logix Platinum Series (Neopor EPS) are tested to provide r-28. They do cost more than their Pro Series (white EPS).

Meteors and other cosmic forces

The meteor comment was nonsensical and should be taken as such. This project is proceeding very badly with the rebar fiasco and now the wall pour. I poured many walls in my early days at colleges, hospitals and the like, we always used a stinger. On warm days you will not get the different truck loads of concrete to bond without it. The aggregate at the end of a truck load has a tendency to float and string out with gravity, without vibration, honeycomb is almost certain.

Jake: Thanks for the insights

Jake: Thanks for the insights from one with a great deal of experience w/ ICF's. Re: "I am surprised at the animosity toward ICF construction on this site, to the point that most comments are negative." I think you may be misreading a bit. I feel that most comments merely point out cautions or non-green concerns about ICF's. For ex, you mentioned: "That said, it took a lot of years and a lot of mistakes." I don't think the learning curve is quite that high with more "typical" materials, like boards. Too, you have to admit that ICF's are not the most environmentally friendly wall building material, hence, not terribly "green", and this is a green building oriented site. Inexperienced people can mess of an erotic dream (I re-phrased that to tame it), but I'd sure rather, for ex, straighten a 10', non-plumb board wall than a non-plumb, 8' ICF wall. As for the R-28 ICF wall, that has been discussed here, too, and unfortunately the assessment of that may have come across as negative, but it is just science. IMO, folks here recognize the importance of ICF's in certain instances, but also recognize where they are not always the "best" product to satisfy various criteria that are deemed important.

Response to Jake Vierzen and John Klingel

Jake and John,

Thanks to both of you for your valuable comments. Good dialogue.

Hein Bloed: mr Roger has yet

Hein Bloed: mr Roger has yet to reply and tell us if they were able to fix the top of the walls,

civic engineer ??? are we talking about a house on a concrete foundation here or a bridge ??

True, the point is not to get voids, but it is also inevitable ( or almost ..especially for newbies in ICF ) because we cannot see all of the concrete settling, and i don't think that anyone would like to remove all of the EPS forms to verify if everything is all right!

I see poorly formed concrete foundations/footings every month in here, because crews always have inexperienced workers and are pushed to work faster so they can pour many more projects ($$$) in the same time frame ... i have yet to see a failed section of a house because the foundations were not vibrated or they poured half of it from 1 corner ..

there is a very large safety margin for regular houses on footings and foundations.

John : non green state of concrete buildings could be debated, insulation used has pretty much the same impact as all others ( less than XPS but a little more than P iso ? )

Concrete carries alot of embodie, but concrete buildings usually outlast wood framed buildings by a multiplicator...also air sealing requires less tapes and peel stick etc...

alot of details would have to be considered to be able to compare ICF to other efficient construction methods , and i don't believe that anyone has done a detailed study on this.

There is also alot of sand and rocks in concrete mass..which looks pretty natural and local products to me!

How many inches of EPS on these blocks ?

Where does the R28 come from ? i don't believe i see 3-4inches thick blocks here nah ?

ICF manuf are always a load of BS when it comes to total wall R value.

and i've had a recent discussion with local EPS manufacturers ( 2 largest in quebec )

and they both work with BASF for the Neopor and one told me to expect approx R4~R4.25 from a type 2 and the other tested out at R4.1 in their lab for their type 2 ..so no 30% increase here,

the BASF rep told me that with the correct graphite amount, internal reflectance of radiation brings performance in some specific situations up to equivalent of R5 of EPS/XPS, but that is still always situation specific and equialance numbers.

Lastly, i feel that alot of builders are afraid by ICF because of the possibilities that something might go wrong and the implicated costs. Here most foundations are formed and poured by groups that only do that ( must be similar in usa ?? ) and builders usually just pass the work on so their guys don't need to have any experience and leave the risks to the foundation guys.

The 2 local (in my municipality ) that tried ICF ( one was a very very large house worth 2-3 millions )

had zero experience before their first attempt, used a lower end product that brings risks factors up

and both had a very bad experience and never used ICF again after the 2 buildings.

Risks = -$$$ on profits

Wood framing has no risks associated with it, as u can always redo cut arrange fix level in a very short work time.

in hope i didn't write too many different things, please excuse me if i do not make too much sense,

hard to find time to read/write during work hours! :p

ICF fans and foes

My family and I live in a 3400 SF 3 story ICF house near Jacksonville, FL

It heats and cools for an average of $30 per month using a WaterFurnace ground source heat pump, a 3 ton package unit nearly always locked in low stage, barely over 2 tons. That suffices for outdoor temps ranging from 20-100.

The house has 50 windows and leaks 1600 CFM 50, which seems to be just enough that we don't need mechanical ventilation.

Humidity stays around 40% all winter, 45-50% all summer. It does wander up to 55-60% during weeks when we neither heat nor cool in shoulder season.

House is dead quiet, suppressing both boat engine noise from the abutting busy waterway and aircraft noise from a nearby naval air station.

Exterior walls are not termite food. Termites could work their way in and chew up some molding, but that risk is minimal enought for me to forego termite bond payments so common in our area.

What's not to like?

Civil engineers instead of cowboys

Jin Kazama asks:

" Hein Bloed: mr Roger has yet to reply and tell us if they were able to fix the top of the walls,

civic engineer ??? are we talking about a house on a concrete foundation here or a bridge ??"

We are talking about quality. And safety.

To which these builders as shown in the video have no acess, neither physically nor intelectually.

With a bulging like that as shown the entire wall was at the edge of collapse during the cast. Risking peoples lives working on the funny trestles with their meat colloured protective gear.

The cowboys themself did not even realise what is going on.

For example that the plastic fixings within the EPS walls (holding inside-outside together) had bursted, the EPS(or XPS?) had been damaged by breaking internally.

That the steel re-inforcement (the rebars) sank to the bottom.

Since the few rebars being used (and propably of the wrong quality) were held by these plastic fixings/spacers.

Which collapsed, fell downwards together with the steel reinforcement within the liquid concrete, hence the bulging.

Amateurs there are plenty, Jin Kazama. They avoid professionalism, not necessary they are told.

These amateurs can't supervise the cowboys, are their prey.

Thanks heaven there is a video, evidence enough for a court case.

And a forum like this.

Hang them up high.

PS

In Europe the job of casting concrete is only allowed to be done by professionals.

Due to the risks.

A training to become a professional concrete caster takes 1-2 years. Full time training.

But that's Europe.

Fraunhofer is now training US-builders in the USA, they have just started though.

There is a big ignorance in the trade, so the US education authorities.

So they have hired teachers from abroad, no teachers available in the USA.

Did you know that most USA architects are not able to build an arch :) ?

Response to Hein Bloed

Hein,

According to my viewing of the video, the wall leaned out of plumb. It did not bulge. Nor did I see any signs that the internal plastic webbing failed, nor that the rebar was displaced.

I am sure that workers in Germany have clothing that is colored to meet your fashion sense. However, your denigration of the intellectual capacity of U.S. workers is unfounded and insulting. Although the U.S. doesn't have the apprenticeship programs or professional certification methods used in Germany, Americans, on average, are no stupider than Germans.

Questions

I have watched the video and listened to Roger’s narration several times, and it sounds like there were a couple problems, but they were successfully corrected. But I have a couple questions that perhaps Roger can address here.

When the wall went out of plumb, did the whole wall shift to lean outward; or did the two sides of the foam blocks spread apart relative to each other? I cannot tell from the photo.

If it was the latter, then the ties inside of the blocks must have broken. If that happened, I don’t see how they could have pushed the bulge back in without applying pressure to both sides of the wall. And even then, the pressure would have to be extremely high in order to displace the wet concrete back upward.

In the video, it does appear that the whole wall leaned and went out of plumb, but then what generated the force that caused that?

Also mentioned was the fact that part of the wall rose up during the pour. I assume that this would be caused by the hydrostatic pressure of the wet concrete forcing its way through the horizontal joints of the blocks. If so, that would be a typical response in all wall pours with these blocks as forms, so how is that prevented in typical practice?

If the blocks did separate at their horizontal joints, wouldn’t the separation gap immediately fill with concrete? If so, in order to push the blocks back down, that concrete would have to be displaced back out of the block joints. Wouldn’t the aggregate in the concrete prevent the joints from being squeezed back together?

plump or bulged

Acording to the video an entire truckload of concrete was missed at the end of the day. And had to be added on top.

This can only happen with bulging of the shuttering. By increasing the volume of the void.

Quote:

" We had to await delivery of concrete twice – once because it was being pumped into the Logix faster than deliveries could be made, and then at the end when the crew realized we were short about 4 yards of concrete. Uh-oh. It’s after 5 p.m.

Fortunately, the concrete plant remained open, and quickly dispatched another truck to complete the pour. "

gaps between ICF units

Ron Keagle asks:

" If the blocks did separate at their horizontal joints, wouldn’t the separation gap immediately fill with concrete? If so, in order to push the blocks back down, that concrete would have to be displaced back out of the block joints. Wouldn’t the aggregate in the concrete prevent the joints from being squeezed back together? "

That's correct , Ron.

There must have been plenty of air in the mixture to allow for the corrrection.

For a correct reinforced casting not only horizontal but also vertical reinforcement steel should have been used. The weight of the steel then would hold down the foam provided the reinforcement had been correctly joined and fixed to the last row of ICF.

The drilling into the basement plate was a sign that this wasn't a professional casting job, the vertical bars should have been integrated into slab reinforcement before casting it.

Hein : i have to admit that

Hein : i have to admit that the builder's crew is a bit funny looking, but doesn't deserve destructive comments. That said, there is a very detrimental lack of quality workforces in north america

( canada and usa ) and it is prooving very hard to find workers with interest and honor, and things do not look good for the youglings growing up either ..

"their meat colloured protective gear" ahaha i'll use that here from now on :p

They used the bracing inside as stated ... should be safe ...but then

have a look at the picture

looks like the whole wall is off plumb , or at least the last 5-6 ft of it

now Roger states :

"""""""""""""""The top of the wall isn't plumb. One reason that some sections of the ICF wall aren't quite plumb is that the contractors used 10-foot-high bracing for the 12-foot wall.""""""""""""""""

if they used the 10ft bracers, and the bracers are secured to the 10ft first feet correctly,

there is no way the hole wall can go off plumb like this unless they screwed somehwere

( or didn't use screws somewhere :p )

If it would've been a question of not having braced the last 2ft..only this 2ft would've gone out of plumb, and would be limited by the tolerance and slak of the forms

When i poured the last 36" of ICF at the top of my 40ft walls ( the last 36" is the base of the roof terrace parapet ) , it was very difficult and dangerous for us to install correct bracing, and we had to adjust some parts of it because it "slided" a bit out of plumb ( it was minimally braced with with 2X4 and some ply strips ) but the remaining 9-10ft of poured wall under it didn't move a bit

and we used far less braces than recommended by the manuf.

In hope they were able to correct the out of plumb walls.

Hein again: i understand what you are trying to say, about craftmanship and quality of end product,

but at the same time, going directly to suing people and hiring civic engineer to verify the structure without us knowing if they were able to "fix" it before it solidified, is a bit overdoing it.

Then, how would the rebar fall in the concrete ?? i don't understand why you are implying that it could ebcause the plastic clips go in between the forms, if a plastic clip fails, the block buldge and or fails very quickly.

The "clips" for vertical rentetion between blocks is another thing, that could've fail, but that would make the rebar "drop".

I still don't like this kind of ICF forms, and still believe that the structural "ties" are wrongly placed in most ICF products.

And would like to see much thicker ICF forms being ontroduced by more manufacturers.

Was there no vertical rebars used in this system ??? euh What??

Ron: if the clips break and there is a buldge, u better just screw plywood over it on both side to make sure it doesn't give, and forget about it ..

craping foam to get a flat wall is much easier and the impossible task that is to push the buldge IN

( the only way i've seen it done was by screwing plywood over it on both side and drilling through all of it, then use a piece of threaded rod with wash/nuts ) to adjust it before too much concrete is used on top and makes it impossible to push it back in )

Roger: was there any plan to use a "peel stick" membrane on the exterior of the forms ?

If so, why not isntall it before the pour ??

Still i don't understand why someone would work in cement pouring all day and not wear a minimum of shirt/googles/gloves ... helmets anyone ? )

ron: if only cement/sand when in between, it can be squeesez back some ...for rocks

to get in between the gap has to be larger than the size used.. was it 1/2 or 3/8 here??

if the gap opens more than 3/8 i think there will be a disaster..so mr Roger probably meant that the blocks separated some ..let's assum 1/8 or less..which is then possible to push back in a little,

if it is done before too high concrete is poured on top of it

Roger responds

Bottom line: I am very disappointed with our foundation walls, and I would not use this crew again to assemble and pour an ICF wall. I expected much tighter tolerances in plumb and level of the top course.

The crew had decades of experience with standard concrete forms, but none with ICF. They hired a consultant who had extensive experience with ICF, but not Logix. The consultant laid out the first several courses quickly on the first day, based on survey points marked on the footers. He trained the crew that day to continue assembling the block wall, but did not reappear until the day of the pour.

We were very pleased after the pour was completed without incident. However, the results in retrospect were far below my expectations. The top of the foundation varied by as much as 3/4," and the top of the walls were out of plumb by up to 2 1/2". The lead framer spent over 40 hours to ensure the bottom plate of the wall was absolutely level across the entire foundation, and back to within 1/4" of the plans. That meant that some areas of the bottom plate extend beyond the external face of the ICF, which presented additional challenges for outside wall finishes.

The Logix rep never did show up when the wall was being assembled to offer technical help. After the wall was completed, he attributed the uplift to failure to properly use enough 1X to keep the course from uplifting during the pour, and not properly bracing the walls, even though he provided the braces.

In addition, the video show how the crew tried to flow the concrete under the window. The were successful on the first window, but each window after that had increasingly larger voids, to as much as 10" below the bottom of the window. This is below grade, so I was very concerned that freeze/thaw cycles would simply crush the foam block over time. The crew recently came back to fill the cavity with hand mixed concrete. I hope it bonds with the now cured concrete and we don't have future leaks.

To respond to some specific questions:

- the vertical rebar was spaced 16" OC. Holes had been drilled into the footer. Rather then install shorter lengths of vertical rebar as the wall was being built, they did not install the vertical pieces until the full height of the wall was completed. The crew dropped the rebar into the wall and felt for the location of the hole. The idea was the hole would pin the rebar at the bottom, and only tie the vertical pieces at the top. They claimed they were successful. I have no way to confirm that, and based on the overall quality of the wall, remain skeptical.

- Don't know the size of gravel used. Do remember it was a 6 slump for the concrete.

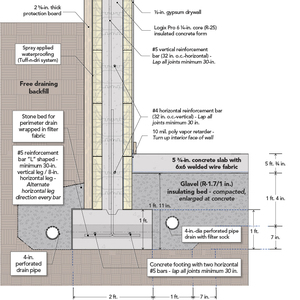

- We do have drainage tile both inside and outside the footer.

- The 6" block has 1 3/4" thick foam on both the inside and outside of the block.

- We did use a Logix provided peel and stick waterproof membrane on the outside.

Despite mfgr claims, there's much more to building a quality ICF wall than simply stacking Lego blocks. I would only consider building an ICF wall if an experienced crew with a proven track record was going to do the work.

Roger: 6" block has 1.75"??

Roger: 6" block has 1.75"?? please explain

from LOGIX website :

LOGIX Platinum Series delivers R28 with our regular 2.75" panel thickness.

is this what you used ? R28 is not too far off at least.. from discussing with Neopor rep and EPS producers locally, gives me more in the R22 region , but at least they are not pushing a R40 wall soemthing with only 5.5"or EPS :p

How did you get 3/4" of height difference ??

Why did it take 40 hours to get the footins to +-1/4" ?? what is the total length of the project?

Is the 3/4" height problem where some uplift occured ??

About the vertical rebars, @16" seems good, are you saying that they pre-drilled the footings

and then tried to drop the rebars in a concrete hole ??woa ..

The Logix clips don't help much to hold the rebars at the correct spot, some manufacturers

use ties that have a closed inner section, so that the vertical rebar cannot be off center more than 1-3 inches and can never get near the blocks ( which is what we do not want it to do )

The winows opening bottom will be at ground level ? I didn't think about this when i commented

on the voids under the windows ( i never designed windows that start at grade level )

Of course if backfilling is pushed the foam will crack...

They could've used some concrete latex primer before filling it by hand if you wanted a sure seal,

but again, should not be much water and fill pressure at near window level.

Looking at the video again, i don't see any peel stick on the blocks while pouring,

unless it is a color matched peel stick membrane :p

Should've been ON before pouring, but neway no blowouts !!

Bottom plate = ??

Response to Jin

Sorry, Jin. Typo. You are correct about the 2.75" foam thickness. Sorry, I don't have the plans readily available, but I think the lineal length of the foundation is about 400.' Uplight occurred in many places, but is most pronounced in the vicinity of the garage.

Yep, about dropping the 10' and 12' rebars from the top of the Logix wall into holes drilled into the foundation. I was told it would be too hard to use shorter vertical rebars and tie them off as the wall is built.

The windows in the basement are actually about 4' below grade, with Bilco Scapewells on the exterior.

We did use a peel and stick membrane provided by Logix on the entire exterior wall.

My 2 cent question

This whole ordeal makes me wonder about using ICFs (we will build this summer so this is important to me). Is there really that much advantage over a standard formed concrete wall and then just add sheet insulation to the inside and outside later? I'm not seeing the big advantages especially since concrete crews have so much experience with setting pouring and stripping forms. It seems like adding insulation afterward is fairly easy and straight forward process. Why jeapordize the foundation wall?

Response to Karl Overn

Karl,

I see no flaws in your logic.

Plumb Walls

There is no reason why an EXPERIENCED ICF crew cannot get a wall level and plumb. I think the problem falls back on that the crew was NOT experienced with ICF. I know plenty of concrete guys that would have no clue on how to install an ICF wall properly. There are 2 trades involved; concrete and ICF.

I do hope the rest of this project was completed in a proper and square fashion. It's a shame that guys like this crew give ICF a bad name. A crew like this will do more negative PR damage than any amount of positive ICF advertising. People remember the bad and forget the good in most cases. It's not the thousands of times the car performed flawlessly but the one time it broke down, that is what people remember and hear about. The same goes for ICF.

Straight walls? We don't need no stinking straight walls... So said the ICF crew as they were banished into ICF hell where they will spend eternity making sure the walls are plumb while being jabbed with a pitchfork.

I've been involved in a

I've been involved in a couple of ICF pours, including my own foundation, which I did mostly with the help of my wife, and with a bunch of FHB editors on pour day. We used Eco-Block - not sure they're even around anymore. Simple, 8 in. reinforced wall.

In short, I'd do it again in a heartbeat, but I'm an experienced construction hand, and had a bunch of experienced helpers (mostly carpenters turned editors) for the pour. And, I had a vested interest in keeping the foundation square, plumb, and level, unlike a concrete crew who'd never see the job again. I verified these things as we poured and tweaked as necessary. I doubt I'd consider hiring a concrete crew who normally worked with tradional forms. They'd bring a set of expectations to the job that simply don't work with ICFs. In fact, assembling ICFs is work more suited for carpenters than for concrete guys, and concrete-nervous carpenters are really good to have around on pour-day.

My advice to the guy who's considering ICFs is to hire an experinced crew. This isn't work for most DIYers, or for most concrete crews.

Don't do it

Do not use ICF. Lots of reasons. If you want an insulated concrete wall, have it poured with insulation attached. Reasons: Extraordinarily time consuming. You can't get the top flat or level. Can't use simple waterproofing. Completed, with waterproofing, costs at least 4x poured wall. Believe it. Voids are inevitable. Cutting for plumbing and electric is much harder than described by ICF advocates. Provides hidden entry for termites. If you are tempted to use ICF, just take a couple of asprin and wait for the thought to pass. Insulating capacity doubtful due to spreading joints that require hours to detail. You can get your energy efficiency other ways- do not do ICF. I would be glad to go into further detail if anyone is interested.

Log in or create an account to post a comment.

Sign up Log in