Building code requirements for stacked window headers, bracing, and stucco over foam

We are building in climate zone 5 and the county currently enforces the 2009 IBC & IRC.

We prepared a list of questions for our building inspector, some of which are location specific, but since we have gotten no response we figured some of this is probably common knowledge.

1. Do non-load bearing walls require structural headers?

2. Can vertically stacked windows of the same width share a header and king studs?

3. This is dependent on soil type but does this seem adequate to prevent frost heave/cracking if the base is 6″ well compacted base course: 4″ monolithic slab with a #3 rebar grid 16″ O.C. and a 18″ deep, 12″ wide footing with 3 x #5 rebar. Frost barrier of 2″ EPS foam extending 4′ horizontally out from slab edge.

4. Is there a wind bracing requirement for each wall (minimum wall area without fenestrations? Our South wall has quite a bit of glazing so we want to make sure there is adequate sheathing (3/8″ OSB) to brace the wall. This is wind zone 1.

5. Related to #3, is there a minimum distance that windows/doors need to be from each corner? I gather the 2012 revision requires 2′ from a corner to the nearest door/window but not sure about 2009. Also aware that this can get quite complex and location specific.

6: Have you seen any issues with stucco sagging / cracking when applied over 1-2″ ridgid foam (i.e. sheathing – foam – vapor barrier – lathe – stucco) on a 2×6 framed structure? Would this require special fasteners? I saw this article referenced from another GBA post, but it’s a bit beyond me.

https://buildingscience.com/documents/bareports/ba-1204-external-insulation-masonry-walls-wood-framed-walls/view

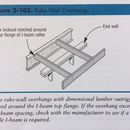

7. Is the attached photo (Figure 2-105 for JLC Field Guide) an approved method for adding rake wall overhangs to I-joist rafters? Perhaps this is a question for the I-joist manufacture. Our I-joists are spec’d for a 15 psf dead load (metal roof) and 40 psf live load (snow). We got those numbers from the guys at Randall’s but please confirm.

Any help is much appreciated!

Regards,

Zane

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Zane,

Some GBA readers are likely to help you on at least some of your questions. But it seems to me that there is ample evidence that you need to hire an engineer.

That's what engineers do: They perform calculations that allow them to answer questions like yours. Hire one.

And get thicker sheathing, OK? You don't want 3/8 inch OSB.

Thanks Martin,

Would you recommend 7/16 OSB for wall sheathing?

Zane,

I certainly wouldn't use anything thinner than 7/16 inch.

But guess what? Your engineer gets to specify your sheathing thickness -- especially since you have an unusual wall with lots of windows -- so my opinion doesn't matter.

Zane,

1. Yes, unless you have a licensed engineer or architect note otherwise. Or if you have a CEO with enough common sense to realize they aren't usually necessary.

2. No, unless you have a licensed engineer or architect note otherwise.

3. If you can meet the prescriptive requirements of R403.3 then yes: https://codes.iccsafe.org/public/chapter/content/4940/. There are additional options but only a licensed engineer can approve them.

4 + 5. There is a lot to consider when it comes to wall bracing. See R602.10: https://codes.iccsafe.org/public/chapter/content/4942/.

6. I have no experience with stucco, sorry.

7. Yes, this is a standard detail. See manufacturers' specs for limitations.

Michael -

Thank you very much for that information. The iccsafe website is definitely an invaluable resource. Structural headers above all windows are definitely cheaper than an engineer. I have attached a framing plan for reference.

Martin -

In our county certain alternative construction methods require an engineer's stamp. One of the incentives for building stick frame is to avoid that additional expense. I apologize if these questions are too open ended to warrant a detailed response, but nothing about this structure is exotic, I was just hoping for some guidelines and further education in the interim before submitting plans. I say this with the utmost respect as I don't mean to burden you or others and have found your articles and posts extremely helpful thus far.

Regards,

Zane

Zane,

It's really hard to give engineering advice based on a verbal description -- at least for me. There are a lot of variables, and casual advice offered on a web forum can be misleading. (Of course, Michael Maines is much better than I am at providing engineering advice. Thanks, Michael.)

I'm glad that Michael was able to step up to the plate and provide such useful answers.

Good luck, Zane, with your project.

I really appreciate the help and definitely understand the challenges of answering an open-ended engineering question online.

Would you recommend APA Rated OSB for Wall Sheathing? If so, would 7/16 APA 24/16 do the trick (24" oc)?

Moving to 19/32 APA 40/20 for the roof decking.