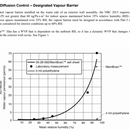

Certainteed Membrain Permeance

Was looking at the permeance chart for Certainteed Membrain. Looks like at 40% RH or so, permeance is greater then 1, probably closer to 2. I’m looking at this for a basement, Zone 5 Toronto. 40% RH in a basement is not that high, so curious as to GBA member’s thoughts on this product. It seems like it potentially would allow to much diffusion through the product during the winter months, if RH is greater then 35%.

Also, does anyone know if Membrain requires drywall to be installed and painted to function correctly? I came across a few references to that but have not heard definitively. Was hoping to leave it unpainted as the basement will remain unfinished, and I have no desire to drywall a ceiling.

Lastly-I have seen that many on this forum mention that to use rigid foam as a vapor barrier (forget the Membrain in this case, forgive me for jumping around), drywall must be painted with two coats of latex paint to function as an interior vapor retarder. Why is this the case? If the rigid foam provides a perm rating of <1, why is this additional step needed, assuming it is taped/canned foamed as appropriate and appropriate thicknesses for dew point control were used?

Thanks,

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Keep in mind that it's not how much moisture gets in, it's how much moisture is getting in as compared to how much is flowing out. So 2 perms can work fine.

Make sure you aren't looking at comments about exterior foam. This often does require a Class III vapor retarder, often provided by latex paint. But this has little to do with interior side foam.

Correct about the exterior foam...I should have caught that. Thanks.

Is Intello worth the upcharge? Seems significantly more expensive, not sure if it adds that much more value then Membrain...certainly is much less permeable in lower humidities, which may be irrelevant given your comment.

Where are you putting it and what do you want it to do? On the walls, the ceiling, or both? And what insulation are you combining it with?

Basement walls/rim joists. Combined with 2 1/2 inch unfaced EPS, R10, 1.2-1.4 perms. I was going for more breathability in the Rim Joist area, the walls it doesn't matter so much-but Canadian inspectors love their poly so I was considering the same set-up on the basement walls. 2x4 walls/Roxul R14 batts after the foam, Roxul in the rim joist after the foam. Anyway, the original questions surrounded whether Membrain was to vapor open in what I consider somewhat normal RH% levels-unless it's the dead of winter, RH% would probably be between 35-45%.

Alternative was ~2 inch faced GPS, perm 0.5, R10. No smart vapor retarder, unless the inspector pushes for one.

Thanks for the input.

Joe Lstiburek wrote an influential book around 2010 where he recommended that basement walls be able to dry to the inside. He has since recanted that advice and now believes that basement walls cannot dry, and should be built airtight, impervious and of non-porous materials. I wouldn't put fluffy insulation below grade, it just seems like asking for trouble.

Rim joists can dry, and in your climate they would mostly dry to the exterior. They should be ruthlessly air sealed and have enough foam insulation to the outside of the fiber so there is no possibility of condensation.

Cut-n-cobble foam tends to not form a reliable air seal. And air sealing is much more critical than perms.

Consider rigid foam sealed with two-part spray foam. With the ratio to air impermeable insulation taken from the spray foam info here (plus whatever your code requires).

Thanks Jon. I'll consider that.

In terms of evaluating all my options, does anyone have any other thoughts on Certainteed Membrain being ok in this application? Thoughts vs. Intello?

I may be highjacking this thread - perhaps I should start a new one - apologies if so - but my situation is somewhat similar. I am in Sudbury, on the cusp on Zone 7. I need to finish the ceiling of our vaulted second storey. We have two overlapping layers of foil-backed iso (3" total) directly above our rafters. We have added about 3.5" of wall-tite spray foam to the underside of the iso-foam panels - filling the original rafter bays. The rafter depth has been expanded by 3" - we will fill this with Roxul to give some soundproofing and fire resistance.

We want to finish this off with shiplap vs. drywall. We do not technically need to place drywall under our shiplap re: fire spread. I would like to avoid the overhead install of drywall here if possible. I would like to be able to place the Roxul into the ceiling entirely before even beginning to put up the shiplap. I would like to use a vapour permeable membrane to hold it in place (as the spray foam is our vapour barrier and I can't just use plain old poly). Another benefit to using a membrane would be to prevent Roxul fibres from entering our living space through any gaps in the shiplap - this is my main concern (along with not trapping moisture in using a membrane). Am I right in thinking that the Roxul fibres could make their way into our living space through the shiplap?

I have been looking into MemBrain and IntelloPlus as well. @johnJones171 could you share any sources you might have for MemBrain in Ontario? I did just see a small quantity posted on Kijiji in your area. IntelloPlus is pricey but at least there is an easy online order option. Also - how robust is MemBrain? 2mm . . . does it rip or tear easily if some of the Roxul it is holding were to lose its friction-fit and puts pressure on it?

Finally - what about simply using Tyvek in this instance, or, a perforated radiant barrier? I should also mention that I am installing a Luna E2 spot HRV paired system in this space - with a humidity sensor in the control unit.

Thank.

Membrain isn't sold in stores anymore in Ontario, at least around my area. Lowes used to carry it years back. Walmart.ca is the best source I know of...the only other one I know of is Ebay.

Thanks John.

>"It seems like it potentially would allow to much diffusion through the product during the winter months, if RH is greater then 35%."

Don't confuse the indoor RH with the RH inside the wall cavity. The dew point of the air inside a fiber insulated cavity will track the coldest surface, which may be closer to the outdoor temperature. With 3-5 perm paint on wallboard between the MemBrain and the indoor air, the air on both sides of the MemBrain will have a dew point pretty near the coldest part of the exterior wall surface.

So it's really the temperature of the above grade exterior that determines the RH at the MemBrain, not the humidity of the indoor air.

Thank you, that was the piece I was missing. However, if one was not finishing the entire basement, and thus left the drywall untaped and not painted in those areas, would Membrain still be appropriate? I'm assuming this changes how Membrain behaves somewhat. Would a tighter smart retarder like Intello be more appropriate in unfinished areas?

Thanks for the input.

>"... if one was not finishing the entire basement, and thus left the drywall untaped and not painted in those areas, would Membrain still be appropriate? I'm assuming this changes how Membrain behaves somewhat. "

MemBrain becomes MORE appropriate if the drywall isn't painted.

The effect of the paint on MemBrain behavior is pretty small. MemBrain (<1 perm @ 40% RH) is quite a bit more vapor tight than interior latex on drywall (~3-5 US perms, also varying a bit with humidity) most of the time, only approaching latex paint's vapor openness when it's getting humid enough to start growing mold. With MemBrain AND paint the paint becomes the limiting factor for the drying rate, but MemBrain is what determines the moisture accumulation rate.

Unpainted drywall is north of 25 perms. Untaped drywall is a lousy air barrier. When detailed as an air barrier MemBrain would allow you to leave the drywall untaped & unpainted without much risk.

Tighter smart vapor retarders are fine, but it's not always worth the upcharge for Intello. In basements with a lot of moisture in the foundation if the wall foam isn't air tight or a more vapor open type (eg unfaced EPS) it might even work against you, limiting the ability of the assembly to relieve ground moisture vapor drives.