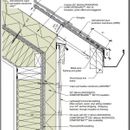

comfortboard 80 on 12/12 roof

Energy retrofit on 1906 balloon-framed farm house in climate zone 6. Rafters are 3×5 approximately 30″ OC. Currently working with structural engineer on strengthening framing to carry additional weight of updated roof. Current plan is to fir out 3x5s with 2×8 and place R30 fluffy insulation inside. Maintain existing pine board sheathing. Then new WRB, then R16 to 20 (4″ or 5″ of comfortboard 80) then ventilation gap, then sheathing and standing seam metal roof. See attached diagram from Rockwool folks. Need to confirm that comfortboard can work in this situation and the thicknesses are correct. Will either double up the 2″ or 2.5 inch product depending on availability ( hoping for the 2.5 so I can get over R-49 in my roof)

Questions:

1. As long as roof is ventilated, are the interior/exterior R value ratios acceptable (in other words, is the 51% rule only for nonventilated roofs?)

2. Using comfortboard on steep pitched roof? (Has this now been used in enough situations to be considered safe? I must admit to never understanding why it wasn’t a good idea to begin with)

3. Rockwool indicates a 2.5 inch gap for ventilation, that makes for a long screw to reach 1.5 inches into the rafters below–any chance for 1.5 inch gap?

4. Lastly, any detail drawings or insight into building the rake for the overhangs on the gable ends that need to attach to foam? Place solid 2x material on the edges with no thermal break?

Thanks,

Brad

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

The ratio still matters. Without the right amount of exterior insulation for condensation control you can get moisture buildup under the roof deck. The rockwool does offer some drying potential but the question is whether it is enough to keep you out of trouble. Since stack effect will tend to continually push moisture into a roof in the winter time, things that work for a wall won't work on a roof.

Vent gap depends on your local code. Ours is 2 1/2" but I've never seen it checked. One option is to install 2x on flat and cross strap with 2x2 to increase vent space. I guess in this case the vent gap is only for controlling ice building, so you wouldn't have to follow code.

I think the issue with MW on a steep roof is walking on it. I can see the insulation coming apart.

You can ladder frame the rake ends the same a standard roof. Won't be properly vented in that small area but I doubt it will matter.

P.S. Top venting is only really needed in heavy snow country to control ice dams.

Thanks Akos,

I had considered the walking on the MW as a problem, but then wondered, do people really walk on polyiso on a 12/12 or do they work in sections placing insulation and then new sheathing and work up the roof??

This does cause a dilemma if I assume R-30 inside then I need more comfortboard and the cost starts to become a factor. If I switch to polyiso I no longer have drying capacity to the outside, perhaps not an issue, and the project is less environmentally friendly unless I find recycled product.

I could decrease inside to R--20, add R-20 outside and have a better ratio but less insulation--house currently has zero insulation, so anything would be an improvment but hope to be as energy efficient as possible and heat with mini-splits.

The house is not in heavy snow country, coast of Maine, but some snow possible.

Vetitude,

I think most people use other insulation materials here because (A) It reduces the weight on the roof, reducing the size or depth of the rafters. (B) There's higher R value materials (Polyiso) that gives you more R value for both less weight and depth, and is cheaper. (C) Mineral wool isn't the most fun to work with. (D) Vapor permeability hasn't been a concern. It is used a lot on flat roofs, commercially, but practically never on sloped roofs. I'm not sure there's a real reason, it's just the way it is.

If you haven't worked with Comfortboard before, it's locally pretty soft, and relatively heavy. Meaning you can easily poke it with your finger and compress it. I think a 2x3 on edge would indent itself pretty hard, and have a real tendency to roll, once separated from the roof deck by the width of two Comfortboards.

I'd do what Akos suggested and make a T beam of sorts with a 2x4 on the flat and a 2x3 on the edge. That will prevent any of the rolling and excessive compression, while providing a nice large gap for ventilation. Bonus is that down the road, the 2x3 could in theory be replaced if you toe screw it instead of nailing it from behind, leaving the rest of the roof alone. I'd be tempted just to use a 2x4 on the flat, and call it good. It's easier, large enough really, and provides a good flat nailing surface.

Ventitude,

Your roof assembly is strikingly similar to the retrofit assembly recommended by BSC for the US department of energy (you can find it on p. 17 of this report : https://www.nrel.gov/docs/fy15osti/63186.pdf).

I have never used this assembly so I won't comment on it, but I figured out it could be usefull to you or others reading this thread.

Happy building,

Robin Sirois