Concern – Gravel retention under slab

I am building a post frame shop building in 4a.

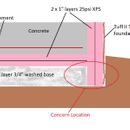

When I pour the slab on 2″ of foam and 4″ of gravel, I will remove form boards and attach another 2″ of foam around perimeter of slab.

I am concerned about voids being made when I remove form board and some gravel falls out since there is no footer to retain the gravel. Once the form board is removed, I will need to trench a little, so I can get the perimeter foam deep enough to stop any mice or other critters that might like to nest in the foam. Foam will be coated with a fiberglass mesh and foundation coating to protect foam from critters or weedeaters.

Solution I am thinking might work: Installing perimeter foam before the pour. Then remove form boards, coat foam, and cured, backfill outside finish grade.

I have already poured my concrete piers with metal perma-column brackets for the load bearing posts and roof.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I'd add the foam inside the form. But EPS, not XPS.

How about wrapping the bottom of the foam with stainless steel mesh to keep the critters out?

Given the climate impact of XPS, it should be EPS, unless you can get the NGX foam from Owens-Corning.

I have the Fomular 250 (25psi) XPS that is recycled from a disassembled building. I cannot afford to buy new foam.

Stainless mesh is very expensive. I have some I got for a crazy give-away price for the top edge of the XPS so termites cannot get to framing and it will be embedded in concrete pour and extend over the foam board and covered with foundation coating. However, it would need a much wider swatch as larger critters will borough a tunnel under a slab here back some distance, so a wall needs to stop their tunneling.

Great that you have foam to reuse. That's better than any of my previous suggestions. And yes, stainless mess is expensive--so that suggestion isn't particularly useful either in this case.

Mikeysp,

I know it is easy to suggest labor to others, but there might be a way to corral the stone. If you have not already placed the stone, I would suggest buying a long roll of 3-4 foot wide heavy plastic to place on the ground such that 18" or so lies on the ground inside the form boards. Flap the rest over to the outside of the forms, then place your stone. After the stone is down, flap the plastic over the stone bed, place your foam, then cast your slab. When you remove the forms, the plastic should hold the stone in place well enough to get the perimeter foam placed. It might be good idea to pin the first layer of foam tight to the slab with 3/8 rebar sections or if you really want to get thermal about it, sections of fiberglass rods used for electric fencing. You might get three pins per rod.

A big question remains as to how you plan on stabilizing the outermost layer of perimeter foam. Can you show how you plan to frame the walls relative to the posts and slab?

And, not to terrify you unnecessarily, but I sure hope you don't have as industrious a band of woodchucks (ground hogs, whistle pigs) as I had at my prior house. One or more managed to pull about two cubic yards of pea gravel out from under my garage slab while making a comfy home for the young ones. Broken glass bottles didn't dissuade them at first, but a combination of barbed wire sections and old carpet tack strips finally frustrated their excavation project.

I have been mulling over the suggestions and possible solutions and I THINK I have a good composite idea.

Do as Jon R says and place foam inside form boards. and then take a very soupy mixed mortar and pour it along edge once gravel is down and compacted to bind gravel together.

Pic: I have some ~2.5" metal washers and 5" red metal screws used for fastening foam to roof panels (got for free). If the red screws are ok to embed in concrete, I will not need to buy tapcons to fasten foam. Either way, I wonder if pouring over foam retaining screws is the better idea than drilling and fastening after the fact? This way, the foam is not loosened when the form boards are removed.