Continuous insulation

I am building a new home with a full basement. I have 2” GPS insulation installed from top of footer to top of the first floor wall without a gap other than the seams where the insulation boards but together. Do I need to worry about moisture from behind the below grade foam working it’s way up the backside of my above grade foam? Should I creat some kind of gap or barrier between the two? Thanks

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

What are you doing for dampproofing concrete walls? That should provide continuity with your WRB.

WRB stops at the mud sill. Basement wall damp proofing stops about 6” from the top of the basement wall so there is no continuity

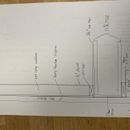

I would provide a break between the two with flashing that extends back to the WRB. This will also make it easier to clad, as the chances of the foundation being perfectly co-planar with the framing above above all round the house are slim.

Unfortunately it is already installed so I’m basically at a point of rip it out and fix it or leave it alone. I’m using a rainscreen so that will help with co planer problem. The seams are taped and I’m not concerned with water infiltration so much as I am Having a moisture problem. Is the flashing for moisture or water shed? Thanks for your reply.

Hi Dasrks

The short answer is no, you don't need to worry about that. The capillary break beneath the sill is meant to prevent moist from the foundation wall from wicking up into the wood framed walls above. However, you should lap the WRB past the mudsill and onto the foundation (or tape it) to keep water and air out. I know some GBA users suggest using Z-flashing where their below and above grade foam meet, but I'm not sure it is necessary. You can tape that joint.

Thanks. I have sealed the mud sill to the foundation with a liquid flash. I am concerned because it’s a brick form foundation that damp air could possibly travel up and behind the WRB and cause a moisture problem. I think the WRB is sealed to the mud sill but I was not able to verify 100% before the foam was installed. Even if it is it’s rated at 33 perms so i think it could potentially let moisture in.

As I see it, you have a continuous (not interrupted by the sill seal) tiny vertical gap from something wet (the foundation) to wood. It could act as a capillary transport or air/water-vapor transport.

In this example, such moisture flow is blocked by a plastic sheet:

https://www.greenbuildingadvisor.com/app/uploads/sites/default/files/Air-sealed%20Mudsill%20Assembly.pdf

I do have a foam sill seal that is sealed with liquid flash on the outside so I think I’m covered from a capillary problem From the foundation but maybe not from the back side of the foam. Ugh!

Exactly - the back side of the 2" foam and maybe the exterior (vs middle which is blocked by the sill seal) of the foundation/seal. Maybe sealant connecting the sill seal to the 2" foam would be enough. Or maybe someone has proven that it's all theoretical and doesn't cause a problem.