Cool roof design II

Hello Again,

I’m looking for help on roof underlayments. There’s a million of ’em out there.

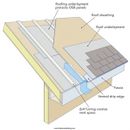

With reference to my original post (COOL ROOF DESIGN), I came to a conclusion similar to Martin Holladay’s. Simply, I can see better ventilation in the design and I’m sure better drying if water gets in there. The attached design was provided by him to another writer and modified by me to include ICF foundation and walls with SIP’s roof and uninsulated wraparound porch roofs.

My original plan was a SIP roof covered with Delta-Trela and then Kynar500 coated standing seam metal. The difference in labor savings doesn’t appear to justify the cost of the Delta-Trela. Roughly $8,100.00 for the underlayment.

So, my questions are for you guys who do this for a living these days. What underlayment do I choose on the SIP’s roof and then which on the primary cool roof covering under the metal? I’m looking for the best bang for the buck here.

Thanks In Advance,

Dune

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Directly on the SIPs you want 15# felt. The purpose is to help pull any moisture out of the panels. Synthetic felt or underlayment will not do that. Use open cell spray foam between the gaps on the panels and a vapor open tape on top of the seams in the panels. That allows the assembly to dry towards the air channel.

Thanks Zdesign,

I was thinking felt as that's all I've used in the past on roofs. Hell of a lot cheaper too. Then place 2x4 vertical purlins and sheet. Next question, what underlayment to place on the primary roof sheathing, and whether it matters if it's breathable or not?

"Directly on the SIPs you want 15# felt. The purpose is to help pull any moisture out of the panels. Synthetic felt or underlayment will not do that."

I'm not sure I understand that. Surely permeability is permeability. If the synthetic underlayment and building paper the same perm-rating, moisture will pass through them equally? Or are you saying felt acts through capillary action to wick moisture out of OSB?

Felt has pretty amazing characteristics, including MORE perm when damp, less normally. Check for tests: I'll bet its way better at wicking sideways through the sheet, compared to the synthetics.

Bryce,

Felt is a variable-perm material, but so is plywood and OSB. I still don't understand what quality it has that would draw moisture from the sheathing.

Any metal approved underlayment should work. Rhino U20 is very cost effective and easy to use. Your mainly trying to keep the condensation from the metal off sheathing. The air channel will help remove the rest of the moisture. Here in NY we aren't required to have Ice and Water Barrier under sheet metal, standing seam or panels so I like to skip that step, plus High temp Ice and Water is rather expensive.

Thanks Zdesign for your imput.

I like the tech reading on Rhino U20, and wonder if it will hang in there for the longevity of a standing seam metal roof. What really interests me is the price for such a high quality underlayment. When you talk about the roof temperatures at times being very hot in the high desert of southern CA, I worry that the wife will have to replace it all when I'm gone. I would like to see the roof extend beyond her years. The metal will be powder coated with Kynar500, so temps beyond the metal should be far cooler than an asphalt roof.

The one thing I can say is that all my buildings over the years are still standing, with roofs in good shape and all I ever used was 15# and 30# felt. So maybe I'm worrying for much of nothing. The last roof I put on was in South Florida (15 years ago) is still going strong, through numerous hurricanes, and I used 30# felt under 50 year Corning shingles. AND THEY GET HOT.

In any event, and with all the input from all y'all, I've been learning a lot and was leaning heavily toward GAF Deck Armor over the SIPs (as it's breathable at 16 Perms and water resistant). Then Sharkskin Ultra as the primary roof underlayment (it's expensive but nail sealable and 50 year warranty). Another plus with the Sharkskin was that you don't need cap nails. I can just use my roofing nail gun. I really like that, but is it worth the price difference in labor? The cost difference is $2300 for Sharkskin Ultra VS. $350 for Rhino U20.

So thank you Zdesign, I'm going to do a more thorough look into the Rhino U20 and I would really appreciate any other comments in the thinking here.

ANOTHER QUESTION: I've seen where guys have left the SIPs uncovered under the cool roof and wondered if you or anyone out there thinks this is a good idea? My SIPs and roof will be borate treated also.

Thanks to All Here,

Sincerely,

Dune

There are metal roof experts, but generally not energy experts, over at https://www.metalroofing.com/forum/ who may be of help.

Weight is an issue also with the cool roof: you're adding a lot of layers.

See also:

https://www.metalroofing.com/spirit/topic/5559/do-battens-result-in-energy-saving-benefits-that-j/

Thanks Bryce,

I'm reading their website. Lots of good information. I do believe a "Cool Roof" is now mandated in California. From what I've seen of the types of "Cool Roof" construction, the maximum PSF added to a roof would be around 7# psf in my case. I believe 3500' elevation is where the design loads change or increase in that area. Only thing I hope to get is a heavy frost. So, I don't see weight being an issue for SIPs generally in the high desert of CA unless your spans exceed 12'. Then, there are several different types of connection splines which improve significantly the transverse load calculations. Slope adds even more to the calculation. The county will tell me what I need and I believe the live and dead load minimums can be achieved easily even with the "Cool Roof" mandates.

Sincerely,

Dune

Are you in a fire zone? If so you should consider a fire resistant layer underneath your metal panels.

https://www.gaf.ca/roofing/residential/products/roof_deck_protection/versashield_ul_fire_barrier

Hello Scott,

You make a good point. I had forgotten about fire ratings when looking at all these underlayments. I went back to check the Sharkskin Ultra and it doesn't mention the rating. The Rhino U20 has a Class A rating in their literature. I'll have to call the company tomorrow, but I'm betting it also has an A rating.

Thanks,

Dune