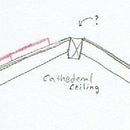

Detailing solid foam panels at the ridge. Hunter

With solid rigid foam panels on a cathedral ceiling roof, how is the ridge itself detailed?

——————————-

The project wil use Hunter H-SHIELD NB on a sloped roof. The panels are to be butted together tight, but what about the ridge? The Hunter documents are silent on this topic. Flexible spray foam? Elastomeric caulk? What would actually last in that application.

These are not T&G panels, and T&G would not mate at the ridge anyway.

San Francisco Bay Area fog zone.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I figure there are three ways to do it.

a) Try to butt them tight

b) Leave a 1/2" gap and single part foam that gap

c) Do a triangle wedge, so gravity helps seal the deal

Your thoughts? How are ridges detailed on a foam sandwich roof?

I'd either go with your option B or you run one panel long and butt the other panel to it, leaving a gap for canned foam. Most importantly, tape the seam as well to prevent air flow; the foam will inevitably shrink a bit and lose the seal that the canned foam initially provides.

How would the overlap method work, without creating an uncaulkable gap or a no-nail section right at the ridge?

(the panels are bonded plywood to wood 2" thick)?

What tape would be appropriate?

In that case there would be a section without sheathing. If the foam is thick, or if you aren't installing another layer above, that wouldn't be a good solution.

Siga Fentrim tape is my favorite for tough situations like this--it's very sticky, and vapor permeable. Other options include 3M 8066 or 3M 8067, which are more affordable but not as sticky, and not vapor-permeable.

If you don't also have insulation in the roof framing cavities, I agree with Walta--a single layer of nailbase on a roof is at risk of thermal short-circuits and possibly moisture accumulation. It woudl be better to install the nailbase over another layer of foam or over insulated framing cavities.

Single layers of foam can be a problem in that no matter how careful you are the joints will leak the only real answer to have several layers with staggered seams.

Consider adding a vapor diffusion port as my guess is there are a ton of air leak in the existing ceiling and lots of moisture will find its way into your foam and needs an exit.

https://www.buildingscience.com/documents/published-articles/pa-foam-shrinks/view

https://www.finehomebuilding.com/2011/11/14/improving-performance-of-a-sips-roof

Walta

The Alaska case is fine, but that's an extreme climate. This roof is in a non-freezing high average humidity area (zone 3 marine).

For regular foam panels, with ply on top, here's what the angle cut would look like. But that won't actually meet up quite perfect at the ridge, right?