Fastening Metal Lath Over Thicker Foam to Foundation Wall

Hello all,

Our foundation walls were just completed and we’re looking to insulate the walls on both the exterior and interior starting with 3-4″ on the outside.

We’d like to face the above-grade portion with a thin stone veneer which requires that we apply MTI Sure Cavity drainage layer, expanded metal lath, scratch coat, etc.

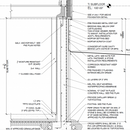

Our drawings (attached) spec’d 2 layers of 2″ foam on the exterior. 1 of those layers is cut off at grade to accommodate the stone veneer.

I would like to apply the stone veneer outboard as much insulation as I can so-as to improve insulation levels above grade, however, I am wondering how much exterior foam can I get away with fastening metal lath and the stone veneer?

Can I do stone veneer over 3″ of foam? 4″ foam? What fastener schedule would I need to use for the metal lath?

Thank you from Wisconsin.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Michael,

Why not put all the R-15 of rigid foam on the interior? That would easier than trying to apply thin stone to the foam. Do you have a complete plan for how all your air, water, and insulation strategies are going to tie together? It's not really something you want to figure out on-the-fly.

Hi Steve,

The interior wall will be insulated as well but R15 is required by code outboard and is really better to keep the foundation warmer. I’m after R30 or so on the foundation wall total.

I do have an air sealing strategy but that should not be affected by exterior foam and stone. The sheathing and mud sill will be sealed to the foundation as primary and I have a secondary air barrier as well through the rim joist and into basement interior walls.

Joe Lstiburek has changed his advice on inward drying if that's what's driving your process. See #2 in https://www.greenbuildingadvisor.com/article/joe-lstiburek-discusses-basement-insulation-and-vapor-retarders.

Thanks Steve. I have 4” of exterior mineral wool insulation above and part of the insulating on the exterior is an effort to have a similar plane on the above and below wall with the finished stone look so it doesn’t have that overhang look. However, I want more than only 3-4” of foundation foam, so that brings some of it to the interior.

My plan is to spray foam an inch or two against the foundation wall after framing a 2x4 energy wall and spray that straight into the rim joist. That is not the primary air barrier though but it will connect with my secondary.

You can look at the tables here:

https://www.rockwool.com/siteassets/o2-rockwool/documentation/technical-guides/commercial/rockwool-cladding-attachment-and-support-details_en.pdf

Depending on the thickness, stone veneer falls into heavy weight cladding.

If you are going with strapping, I think you can skip the drainage mat but check with your stone veneer manufacturer. Also some allow for installation over exterior rated cement board with thinset, much easier and quicker.

Hi Akos,

Thanks! To be clear, the Rockwool mentioned above is for the wood framed wall. The stone veneer will be applied to our foundation wall but I would like to apply as thick of foam to the exterior as possible while meeting fastening/deflection standards.

I would think that XPS foam over poured concrete would have much better compression and deflection resistance than the charts from Rockwool.

The stone product maker Buechel was not able to provide me with this information unfortunately.

Since it is not attached to studs, I doubt you can go from any of the tables. Maybe if you install 1" Z furring, you can use the metal stud schedule from Table R703.15.1 from the IRC 2018.

Probably the simplest is to move all your insulation to the interior or support the cladding on a ledger, this would let you use any foam thickness.

I've been digging through the details on this today.

First, yes, it would be easier to have all of my insulation on the inside. That would be acceptable but aesthetically I think it will be more attractive to have the stone veneer relatively in line (or inward just a bit) from my wood framed wall above. I've attached a drawing on how these measurements would work.

I am also thinking that it would perform moderately better with some exterior insulation from a thermal transfer perspective, but I could be wrong about that.

Second, I found this document from Boral Stone that includes detailed engineering specs for cultured stone (same psf weights as thin stone veneers) over rigid foam insulation.

https://f.hubspotusercontent40.net/hubfs/3974799/Boral%20Stone%20Adhered%20Masonry%20Veneer%20TER%201312-01%202020pdf.pdf

Page 11 provides foam thicknesses, psf weights (including lath and scratch coat) and the associated fasteners to provide adequate strength.

According to this document, you can do up to 3 3/8" of distance from the wall to the underside of the screw head. If you include 3/8" for a drain channel (like MTI Sure Cavity) and lath set mid-way in a 3/4" scratch coat, you're beyond 3 3/8".

With that, I am leaning towards doing 2" of exterior insulation (as shown in my drawing) and the remainder of my insulation value (another R15) would be completed on the interior by framing a 2x4 energy wall on the exterior and then spray-foaming directly against the wall another 2-2.5".

Does that sound like a reasonable solution?

One last mildly related thing... Do I need to tape the seams of rigid foam insulation on the exterior of a foundation wall?

That PDF looks pretty good, using similar fastener schedule for a similar weight product should work structurally but your inspector might disagree. Make sure you get the correct washers, that probably makes the biggest difference in how much weight the lath can hold up.

If you are looking for R15 on the warm side, in your climate you need around R11.5 for condensation control. If you can bump up the exterior rigid a bit, you can skip the SPF completely and insulate with batts only. Not much benefit to going for SPF in this case, just extra cost.

Hi Akos,

From everything I've read on GBA I need to use a basement insulation that doesn't allow warm air through–they're always saying use XPS or spray foam. I think what you're saying is this is not the case if I get to 11.5 on the exterior.

Are you saying that if I can bump up exterior insulation to 11.5, that would allow me to use an air permeable insulation on the interior?

It looks like technically I could do 2.5" (R12.5) on the exterior and still meet the guidelines in that document, however, I can't seem to find 5/16" 5" Tapcon hex screws anywhere.

Is there a special type of washer other than a plaster washer that I need to be sourcing for this purpose?

Lastly, in your opinion, am I better off sticking entirely to interior insulation given that we want to do the exterior stone veneer? This is getting a little more complicated than I thought it would be.

Thanks as always.

The reason you read the recommendations of rigid or SPF on the interior of foundations is that typically they are not insulated on the outside. When you add insulation to the outside, the foundation gets warmer, enough rigid and you elimiate condensation risk.

This is all about the ratio of rigid to fluffy, so if you don't want to go all the way up 2.5" of rigid, you can just reduce the amount of fluffy on the warm side. Going with something like the 3" mineral wool sound insulation (rated around R12) would get you close to the 2" rigid you were initially looking at.

Exterior rigid makes a lot of sense if you want to leave the concrete as the finished surface, otherwise the usual combination of interior rigid+batts is usually the simplest.

Stay away from the standard insulation washers used for holding rigid to walls, these don't have any holding power, the screw just pulls right through. The ones designed specifically for lath such as the beefy 1.5" to 2" ones for EIFS are much more solid.