Flip the blower door?

How often are home *pressurization* tests done? The usual

blower-door run seems to be the “suck” test, looking for cold

air coming in, but it may not tell the whole story. Turning the

fan around seems to be a logical part of a “fog test”, but one

doesn’t necessarily want to blast fog juice all over an occupied

dwelling as even the most benign water-based formulations still

leave behind *some* sort of residue.

I’d opt for simply using warm air as my indicator. Tonight

I ran a “blow” test on my place, using my window-fan lashup

that’s good for about 20 Pa, and let it go for about half an

hour before going around the exterior with the IR cam. This

needed a cold and *calm* night, so breeze wouldn’t take

away any region of air exfiltration and cool it back down.

What I wanted to look for was anywhere that might be letting

air escape, particularly in the upper reaches where stack

effect would generally have air moving out and not in, and

figured that deliberately compressing my warm air out would

reveal such issues much more profoundly and also around the

lower levels of the house. I gave things plenty of time to

settle so if, say, something was leaking inside the soffit

space or through the foundation it would have time to create

a visible heat blob.

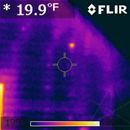

Possibly the most revealing thing was a tiny hot spot under

the siding, corresponding to a location at an obscure end

of a kneewall space that I had seen going a little cold during

the “suck” test. This made it obvious that it was most likely

where a Headlok screw had been put through the foam and then

removed for some reason, possibly a stud miss, and then never

taped over. [pic below.] I couldn’t see that with the same

precision from inside, where incoming air got baffled by

intervening structure and just caused a generally cold bay.

Maybe when it’s not quite as dark and cold I’ll zip open some

siding and actually figure out where that hole is.

The windows looked different under this scenario, warmer around

the ends of the meeting rail and downward — which I’d completely

expect from knowing there’s likely still a little leakage there

despite having shot globs of caulk into the most obvious gaps in

the lineals.

This also turned up minor issues around a couple of panned-joist

ducts running to the exterior walls, where the sill sprayfoam job

had to skip over bays. Time to pull the grilles and see what I

can do down the hole inside.

I was happy to find that the fan didn’t actually move a whole

lot of cold air in; the heat didn’t cycle any more than usual

over the whole hour-plus I was doing this.

_H*

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Hobbit,

People have been using blower doors to pressurize buildings, as well as depressurize buildings, for decades. As your experience confirms, such a test can be instructive.

The most common type of pressurization test, as you pointed out, is the fog test. For more information on fog tests, see Pinpointing Leaks With a Fog Machine.

One reason that depressurization (rather than pressurization) is the standard method for measuring air leakage rates is that depressurization pulls the flappers on exhaust vents (like dryer vents and range-hood vents) shut, while pressurization blows them open.

I generally only pressurize if I want to go in the attic or crawl space, feel the air blowing through leaks, and seal them.

As a general question,

When testing a house for leak ACH etc.. how are vents handled ? are they part of the result or blocked ?

I have not yet dwelved into the vents leak problems in my learning of building science,

but i've always wondered how could those flasky flappers seal effectivly such large openings...

Any specific strategy for high efficiency house vents?

Jin,

Q. "When testing a house for leakage (ACH etc.), how are vents handled? Are they part of the result or blocked?"

A. The answer can be found in this GBA article: Blower Door Basics.

In that article, I wrote:

"Before a blower-door test can begin, the following preparation is necessary: ... In most cases, the following openings are not sealed: Combustion flues and dryer vents.

"Ventilation system intake or exhaust vents (and passive air inlets) are usually (but not always) sealed, depending on the aims of the blower-door test. If the test is being performed to comply with section N1102.4.2 of the 2009 International Residential Code, the section requires that ‘Exterior openings for continuous ventilation systems and heat recovery ventilators shall be closed and sealed.’ Moreover, in many cases a builder will seal passive air intake vents during a blower-door test to determine the theoretical leakiness of the building’s envelope without any passive inlets."

Totally makes sense with regard to attics and crawls, especially the

latter where stack-effect isn't in your favor. I was really amused

by the different and instructive points of view on a couple of known

issues that reversing the airflow gave me. The activity is rather

weather-dependent, and I had to wait for the right sort of night.

I did take into account the only two legitimate holes in and out of

the place -- the HRV ducts. In a "suck" test the backdraft damper

on the exhaust would take care of itself, but for this I run I

obviously had to block that side off. The inlet side closes with a

fairly tight flap when shut down, so that was sufficient for the

purpose. I knew the HRV pipes outdoors would look a little warm

after a while from any residual drift, but they weren't so bad.

What I don't understand is why *all* known orifices in a building

aren't sealed off by default. Why leave flues and chimneys open

at all if the connected systems are shut down? We're testing the

*envelope*, not the holes through it, and it doesn't make sense

to sit there reading CFM as tightness gospel when you know air is

howling in through the draft hood on the furnace. And most of

those exit flap fittings are notoriously leaky anyways.

_H*

I went up and unzipped some siding today, and even with referring

back to the IR shot it took a bit of hunting to find my mystery

hole because it was trying to hide right above a piece of strapping.

Eventually I found it; see pic ... exactly as I predicted, where a

Headlok had gone in and come out again. Running the window fan in

"blow mode" again brought out a healthy airflow I could easily feel.

This is right at the second-floor boundary where there's a lot

of discontinuity in the studs, so whoever was applying strapping

probably tried to go too high at first and wound up mid-field

off the end of the first-floor stud and tried again lower down.

A squirt of caulk and a slap of Weathermate later, fixed.

_H*