Floor-to-Wall Air Barrier Transition

From what I gather, in my area walls are sheathed after they’re braced and the roof is on. I’m very interested in having a good floor to wall air barrier connection but it seems to me many of the solutions are best accomplished when the walls are sheathed before they’re raised.

I really like the idea of cantilevering framing over the stem wall so sheathing can be taped to the mud sill later. However, I’m considering using 2×4 framing and I assume there isn’t enough material to hang out beyond the stem wall. Am I correct?

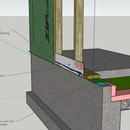

I’ve drawn a potential economical solution to this.

The process I imagine is: the vapor barrier runs up and over the stem walls. A strip of house wrap is then taped to the vapor barrier flap. Framing is installed. The house wrap flap is stapled up onto the studs. A bead of acoustic sealant is spread on the outside of the house wrap near the mud sill (It could be higher up on the house wrap but would require smooshing it from inside the wall cavities later.) Walls are sheathed as normal.

Alternatively, the house wrap flap could be taped to the outside of the sheathing.

Advantages of this approach include less acoustical sealant than other methods and the use of cheaper tape (house wrap tape vs zip tape).

What does GBA think of this? Is there a better solution I ought to consider?

Thank you,

Thomas

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Why not use Zip's recommended detail of backer rod+liquid flash? Seems less work and a more solid seal.

There are also some tapes that will adhere to both zip and concrete. These are not that expensive, some do require a primer for concrete though.

The benefit of either option is that it can all be done in one shot once the wall is sheathed and up.

I'm actually not familiar with their backer rod detail. Are you able to provide a link?

The sheathing/concrete tape would be easy to accomplish. I worry tape wouldn't stick to concrete long term but maybe that fear is unfounded.

The better, and easier solution is to sheathe the walls before they are raised.

Looks like you're going with Zip system? Zip tape the bottom edge of the panel to the bottom plate while it's lying on the ground and that air gap is sealed. Taping the edges is already part of the work flow so you're not switching processes or introducing other products or tools. This will keep things moving and save time/money.

It's a whole lot easier to tape (and roll the tape!) of a wall lying on the ground then once it's raised, so you can bet that's less likely to happen if not already done on the ground where gravity is your ally. Rolling that zip tape is key to long term adhesion.