Footing Capillary Break

Hi everyone,

I have recently started a project with reinforced concrete footings.

My question is: What is the best way to apply the capillary break?

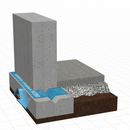

I have applied in the past the strategy presented in Image_0 (attached). However, there was not so much iron on my footings. In this project I will have serious difficulties applying this membrane.

In Figure_1 (attached) the footings can be seen.

I could go with the strategy in Image_2 (attached), placing a capillary break under the footing before the concrete. However, the side would be exposed. I could apply some bituminous paint on the sides, but I would like to have some hydrostatic relief (I have painting cracking in the past because the concrete cracked).

Even a trowel applied fluid instead of the membrane in Image_0, is difficult to apply.

Any suggestions?

Thank you in advance

Joe

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Joe,

You might want to read this article: "Capillary Breaks Above Footings."

The article notes, "Some builders have experimented with installing a capillary break (usually polyethylene sheeting) under the footings instead of on top of the footings. But this approach won’t work well. Why? Because the bottom of a footing is usually lower than the holes in the footing drain pipe. That means that footings are often wet — in fact, in some cases, footings are basically sitting in a puddle."

Martin,

Thank you so much!

My main concern is in terms of curing time.

Do you think regular asphaltic dampproofing do the job? I accept that there is no hydrostatic pressure between the footing and the wall. However, I find hard to accept that regular dampproof will do the job of a waterproof membrane above the footing.

Thank you once again

Joe

Damproofing is different from a capillary break. The asphaltic coating that's been used forever to keep water out of the exterior of masonry walls works well and lasts a very long time, but it does nothing to prevent "rising damp" from wetting the bottom of the mud sill.

The most common capillary break commonly used today is the sill seal gasket commonly installed between the mud sill and the top of the foundation wall. While not the most durable of capillary break materials, it's usually enough to get the job done. Other materials that are commonly used are polyethylene sheet and EPDM membrane materials. I personally like using strips of HDPE sheet for retrofitting capillary breaks into older structures that lack one.

Bill

Bill;

Thanks for your opinion.

Have you seen the attached images to the post ? How would you do the capillary break with all that iron on top of the foundation ? I think a membrane is out of question.

Thanks

Sorry, the pics didn't load for me this morning and I didn't even realize they were there. I see them now though... If the rerod was sticking up with ends, I'd think you could just push a membrane over the tops so that they'd poke through, but your rerod is all looped over. That would make a membrane tricky. A fluid applied barrier would probably be the only practical option, but I'd be careful about getting that on too much of the rerod. The concrete needs to be in contact with the rerod not just for stength, but also to keep things from corroding. As soon as water can wick up into the rerod/concrete interface, the rerod will start to rot and that will eventually damage the concrete. You can usually see this process in action on older concrete bridge support columns, often near the corners.

Regarding hydrostatic relief, your best option there would be to seal the exterior of the wall and put in drain tile at or below the level of the footing so that any water that gets down there will drain away instead of seeping through your wall. If you expect to have a lot of ground water, it may be worth using dimple mat on the exterior of the wall to provide a drainage plain, then tying that into the drain tile at the bottom. With a dimple mat, the worry about a failing waterproof coating is much reduced, since the water will at least not be able to build up any hydrostatic pressure -- it will just drain down along the wall in the dimple mat cavity instead.

Bill

About your only choice with a footing like that is to use a liquid-applied waterproofing material and apply it with a brush. It doesn't have to be very neat or a perfect job. The better the coverage, the less moisture transfer will occur. Another possible solution is using Xypex as an admix with the concrete in the next pour. Your engineer will have to OK it, but this significantly reduces the amount of moisture that will move up through the concrete.

How about Tremco's Tremproof 250? From their website: TREMproof® 250GC is a rapid-curing, high-solids, VOC-compliant modified polyurethane waterproofing membrane that can be applied to damp and green concrete. TREMproof 250GC is a one-part moisture-curing elastomer available in three viscosities: Self-Leveling (SL), Roller (R) and Trowel (trowel intended for detailing work only).

I like the idea that it can be applied to "damp and green concrete". Please let us know what you end up using.

Is there any measured data as to the effectiveness of various footing capillary breaks?

Effectiveness is not proportional to coverage area. Here is a picture of wet paper towel separated from dry paper towel by a plastic film with a very small hole. Soon after, the upper towel was completely wet - not much different than if the plastic wasn't there. I expect that similar would happen if one tried to use a membrane with rebar through it. Thick, durable paint-on coatings or admixtures would be better.

Thank you all for your opinions.

I will give fluid applied a try.

Meanwhile I have another question: We know that concrete lives happy wet. It can be under water, and it is Ok. So, placing the capillary break above the footing is Ok (as in attached image).

How about the rebar inside the concrete footing? That will be expose to capillary water and degrade inside the concrete.

Any thoughts?

Thanks!

The concrete acts to chemically protect the rebar. Basically the concrete inhibits rust formation. When you have problems is if the concrete cracks and the rebar gets exposed, then the rebar will start to rust, opening up and rotting back into the concrete.

Remember that the capillary break on top of the foundation wall is there to protect the wooden silt plate. A capillary break between the wall and footing, while helpful, doesn't protect the sill plate.

Bill

Rebar is embedded in damp/wet concrete all the time with no problems. The only real threat to rebar in concrete is when the concrete is exposed to salts that seep in and corrode the rebar. Also, when concrete is subjected to sulfide or other concrete corrosion, the damaged concrete can allow air contact with the rebar and the rebar then also starts to corrode. So long as the rebar is covered with concrete and not exposed to air, it's OK. Your liquid-applied membrane should have no effect on the rebar.