Getting Around in Tiny Attic to Blow In Cellulose

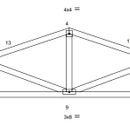

The common trusses forming my attic space provide roughly 36″ of height between the tops of the bottom chords and the bottoms of the top chords at the peak. The roof is 20′ wide and 48′ long with a 4:12 pitch. All that will be up there is some wiring, vent pipes for the plumbing, and an exhaust duct for the bathroom fan. Access is through the gable end. The only time I anticipate anyone going up there after the ceiling drywall is installed will be to blow in cellulose insulation. Attached are a photo and drawing of the trusses, which are 2′ oc. I realize now that a different configuration would have made installing some kind of walking/crawling surface easier, but given what I have, what would be the best way to provide something to get around on for blowing in the cellulose–or does one typically just stand on the bottom chords in an attic like this?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Jeff,

Yeah, in the absence of an alternative that's how you get round.

Right now you probably move from end to end stepping on the diagonal webs just above the plates. If you still want occasional access I'd fasten a 2"x4" between the vertical and diagonal webs at the same height as the top of the cellulose you are blowing in, and run a 2"x10" on top of that.

+1 for building a catwalk as Malcolm described. If the trusses are close enough together, you might be able to get by with 3/4” plywood ripped to fit, which is lighter than a 2x10. You don’t have to meet any deflection specs here, you just need it to be able to safely support your weight.

Bill

Thank you, Malcolm and Bill. I didn't think I'd have enough headroom over such a catwalk, but I figure I'd end up with around 27" below the peak, which is enough for crawling. I have a lot of extra 2x4s and 1/2" OSB. Would 1/2" OSB atop three 2x4s be an adequate replacement for 2x10s or 3/4" plywood?

Jeff,

It's easier to nail a short 2"x4" to each truss (from the centre vertical king post to the diagonal web), so the OSB has to span the full 2 ft between trusses. You might consider doubling it up. Hopefully you never have to go up there again, but it's nice to have the option of easy access for a yearly inspection.

Watch those roofing nails sticking through the sheathng above. I've got a couple of scars on my head from them.

"Watch those roofing nails sticking through the sheathng above. I've got a couple of scars on my head from them."

I've learned the same lesson. I keep an old bicycle helmet for working in tight spaces.

George,

Good idea. Too late for me.

You’ll probably want to keep a smooth surface on your catwalk so that you can slide on it. Sometimes sliding along is easier than crawling.

I’ve sometimes though about using a small creeper like you’d use to work under your car, since the creeper has little wheels and is made to be compact. You could run 2x4s with plywood screwed underneath to make a sort of track for a creeper or site-built sled. I’ve thought of this several times but I’ve never actually tried it.

Bill

Can you blow from below? Maybe before drywall?

Thank you, all.

Malcolm, I was proposing using the short 2x4s as you originally suggested, but laying three long 2x4s and OSB on top of them, down the length of the attic, instead of 2x10s. I expect the 2x4s would be strong enough on their own, but the OSB on top would largely unify their support. I wondered whether the 1/2" OSB would be strong enough by itself across a 2' span. It certainly is on top of the roof, but that's in wider pieces with the long edges supported; I expect it would be if doubled.

Jeff,

Sorry - got it now. That will work fine. I doubt you even need the third 2'x4".

I watched a heavy friend go through OSB roof sheathing where the last strip spanning the trusses at the peak was only 12" wide. You don't want that to happen in the attic leaving you with one leg protruding through the living room ceiling in a shower of cellulose.

Thank you, Malcolm.