Opinions on This HVAC System

Starting to build our zone7 Pretty Good House in a few weeks in Northern Wisconsin.

The main living area of the house is 2,023 square feet with a full unfinished basement (1097sf). We also have an attached garage that we want to be able to occasionally heat.

The WUFI analysis we did shows our heat load (attached) at roughly 24,898 btu/hr including the unfinished basement.

The mechanical designers we’re using are using a design temp of -25. Their detailed analysis using Manual J and other calculations shows the load for the house and basement at 51,996 btu/hr. Including the garage, it goes to 128,257 btu/hr.

I expressed an interest in using mini-splits and they’re open to that, however, they believe that given our basement and garage, using a hydronic distribution system is the most effective. Distributing heat to all areas of the home using mini-splits would be difficult if you’re including the basement (and certainly the garage).

With that, they’ve suggested an Arctic cold climate heat pump with in-floor radiant in the basement and garage and radiators on our main and second floors. https://www.arcticheatpumps.com/cold-climate-heat-pump-overview.html

The Arctic heat pump comes with a buffer tank and electric boiler for backup as the heat pumps efficiency phase out as you get into the very cold temperatures. For air conditioning (which I sort of question as necessary here), they’re using a high-velocity air handler alongside the heat pumps for cooling.

Is this a good system for a house like ours? I think of it as a low energy home with our triple pane windows, deep wall system, high level of airtightness, etc. and it seems like we should have something simpler like just mini-splits, however, distribution is a challenge.

The alternative they’ve suggested is mini-splits for the main floor and second and a bare-bones LP boiler for the basement and garage slabs that would also provide backup heat when the mini-splits aren’t working.

I appreciate any insight you can provide! Thank you.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I'm building a new house in Zone 7 too (design temp -30 F), though smaller--1000 sq ft. I think that gives me more flexibility. We're likely doing a single ductless minisplit in open living/dining/kitchen area, with cove heaters in bedrooms that I'm hoping I don't have to use much if at all given wall insulation values and airtightness. Good luck with your project!

Seems like they're going for maximum cost and complexity with minimal comfort benefit. A regular ducted system (Ducted minisplit or conventional) seems cheaper, more efficient, and provides AC without any radiators taking up space or a radiant floor which will hardly get above room temp in the basement. The garage is a separate issue, a separate wall mounted minisplit could work for that. Add in electric resistance heating for the coldest hours of the year, if your heat loss is closer, you're talking only 8 or 10kw. If they feel confident about their load calculation, ask them for another house in their predicted 52kBtu range's heating fuel usage. Green Bay averaged 7600 Heating Degree Days (65 Base) over the past three years, and they used -25 as their design temperature (99% of Green Bay's daily average temperatures were warmer than -1 over the past 3 years, -11 for Duluth). That means they're expecting you to need about 106MMBtu/year for the house alone. Using an 80% efficient boiler/furnace, that's ~1447 propane gallons/year. A higher efficiency appliance still would use ~1200 propane gallons/year. Duluth has 9300 HDD, so a house closer to there with a true 52kBtu heat loss would use 1500-1800 gallons of propane. $3k - $4.5k/year of heating fuel seems high for a PGH house.

It does seem like it's more complicated than it needs to be. That said, they stressed that heating the basement and garage are really what is driving the hydronic suggestion. We could probably do something simpler.

The 52k btu/hr load is at -25º and heating the entire house to 70º, including the basement. So they described that it is sort of the "highest load situation" for sizing the HVAC equipment only and that it isn't representative of what actual usage would be.

That does seem to be an absurd cost though considering the level of investment this house has in its wall system, insulation, triple pane windows, target 1ach50 airtightness, etc.

I need to investigate how to calculate that.

Wouldn't the WUFI analysis load be closer to the actual usage?

If they have a good Manual J process, it's possible they're right. But the data from houses they've already installed systems for would have to support that and if they don't have that data, they probably don't have a good Manual J process. That being said, it seems high based on the levels of insulation and air-tightness you plan and 25kBtu seems closer. Whatever the heat loss or delivery system (air vs. water, ducts vs. minisplits vs. radiators), a heat pump + electric backup will be cheaper if you pay approximately average US electricity rates in the ball park of $.13/kwh vs propane at ~$2.25/gallon even if you use a large proportion of backup heat.

25KBtu doesn't even cover the whole house effects of a 250 CFM kitchen exhaust fan, perhaps leaving less than nothing for the house's conduction, infiltration and other ventilation losses.

And then there is the wrong assumption that Manual J results in the heat load on design day. The Manual J number will be legitimately higher - because it accounts for the fact that much lower temperatures than design day are common.

Always be clear about which "load" is being specified. Peak, design day with average wind, a windy day below design temps, exhaust fans operating, etc. Then design to always be comfortable. Manual J/D/S for equipment sizing is well proven - trust it, but only if all the inputs are correct.

I agree a manual J can be done correctly and prove valuable - they should be able to provide evidence, especially if it's 100% more than the other calculation.

A 250 CFM range hood fan used on design day would be 25kBtu, but people usually simultaneously use the range :)

Some questions: Do you need a/c given your location? Why do you need heat in the basement and how often will it be used, what duration? Basement insulation level. What is you available fuels, gas, electric, oil, LP? Is cost a consideration?

Hi Jonathan,

1. A/C - Probably not. We do have a lot of south glazing, but A/C would probably be on for only a few weeks a year max.

2. Basement will eventually be a family room / rec space and a guest bedroom. It will probably be unheated the overwhelming majority of the time but being able to periodically heat it would be good.

3. I've included a section of our basement foundation. It is a little unconventional to get the stone facing, but it is roughly R10 on the exterior and will be R18 on the inside, so that's minimum R28 walls. In some locations on the outside there are actually 4" of foam and not just 2", in those areas it would be R38 basement.

The slab has 3" of foam and is roughly R15.

4. We could use electric or LP (propane). No oil or natural gas. I asked them for electric options since I'd rather use electric and offset with solar and that's why they came back with an air-to-water heat pump.

I am open to heating the garage completely separately from the house heating system if need be.

We can ballpark some of those numbers.

Assuming R20/40/60 PGH insulation levels with about 20% decent triple pane glazing.

2000 sqft house tends to have around that much exterior wall and roof area. With the -25F design temp we have

-walls 2000*0.8(70+25)/40=3600

-windows 2000*0.2(70+25)/6=6300

-roofs 2000*(70+25)/60=3200

basement ~5000BTU

add in some air leaks and ventilation losses, take out interior gains, ~20000BTU, so it feels like the WUFI model is closer.

A well insulated basement requires very little heat, lot of times even the duct losses from uninsulated pipes are enough to overheat the basement. Adding in dedicated floor heat is overkill.

For a garage, something that you only want heated intermittently, floor heat is definitely not the way to go, way too slow to react. You want either an oversized wall mount on its own outdoor unit or propane shop heater.

Simplest backup is a wood stove. With a low load place you can always add enough strip heaters to your heat pump to run the whole house during polar vortex days for minimal cost.

Cold climate air to water heat pumps are hard to get right, they can only make lukewarm water when it drops bellow zero. It can work with floor heat or oversized panel rads but you are adding a lot of extra cost for the hydronics. Air to air is much simpler/cheaper.

Hi Akos, thank you.

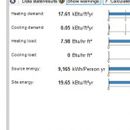

I've attached the report that they did. The summary loads are on page 11. The report includes the garage. I also summarized the info here to separate the house and basement and leave the garage out (attached).

I am not sure why the loads are so different, but the person who completed the WUFI analysis did say that the calculations the mechanical designers complete will show as higher due to how they do their calculations for sizing equipment and ensuring its ability to heat under the worst possible scenarios.

The report includes u-values but not r-values. Our foundation, walls, roof and windows are fairly close to what you describe for PGH. It's R15 sub slab, R28 foundation wall, R37 (2x6 dense pack with 4" of exterior mineral wool) and R50-60 roof (depending on the part of the house).

I would be happy with the basement being heated only occasionally. I also can come up with another heat source for the garage since it will only be used occasionally as a heated space.

The house design does have a wood fire insert planned (Stuv 21/85). This units range is 27,297-47,769 btu/hr. You also can duct the hot air from this unit to move to separate rooms.

I really appreciate the feedback on air-to-water.

1. What would your thoughts be on mini-splits as primary and only having the wood stove insert as backup for those really cold periods? If we're gone on vacation during a cold snap, do I need to be concerned about the house freezing since this backup would only work when we're home?

2. Should I provide any heat for the basement?

3. If you think the mini-splits are a good idea, how would I go about getting the right units from a sizing and distribution perspective? What calculations should I rely on?

It looks like the infiltration numbers are way too high. I think they might have used the ACH50 number directly without converting to ACH natural. This is usually 1/20 the ACH50 number for a 2 story structure in cold climate. I would also double check your 99% design temp, Ashland a bit down the road is -16, won't change the loads by much but still something.

For heating, look for any of the hyper heat units that are rated bellow -20f. Once the heat load is sorted out, my guess you can heat the whole place with a single high static ducted unit (Zuba, SkyAir, LG red with VAHU).

Might be simpler for ducting to go with a separate zone for the 2nd floor, something like a 12000BTU ducted unit (ie ARU12RGLX) can easily fit in the back of the closet.

Most ducted systems can take a resistance strip heater as an accessory. These are a very affordable way to add backup to your system. Just make sure the strip heater is configured properly and only come on when the unit can't keep up.

I wouldn't do a separate system for the basement. For a comfortable basement, what you want a couple of supply registers near the floor level.

Since it is a pretty low load, you can even put a motorized zone damper on the trunk feeding the basement with its own thermostat. Most inverter hyper heat units would have no issues modulating around the change in airflow when this damper is closed.

Wood fire in a tight house is always an issue, make sure the unit you select is well sealed. You'll still have to be careful and always crack a window when running it. Oversized commercial range hoods should always be avoided as well.

Thanks Akos.

Could you tell me a little more about ACH natural? I can't find info on that online. It looks like

I found this article from Allison Bailes about reviewing an audit and did review each of these pieces, but it seems that everything is accurate except for maybe the ACH airtightness and the 99% design temp.

https://www.energyvanguard.com/blog/how-read-manual-j-load-calculation-reports/

I attached a screenshot from the report where it appears that they identify the airtightness method and the spec itself. This is done for each room.

Thank you for the feedback on the hyper heat units. First, I need to sort out the load calculations, as you said. Then, I need to start looking at room loads and figuring out how to get proper heat to each area. This quickly starts to feel beyond my capabilities and ultimately why I tried to hire a mechanical designer. I feel a bit like they're leading me astray though. Is it possible to source this kind of help via GBA? Do you do this type of work or anyone that we can tag?

As for wood fire, does it make a difference that the unit does have its own supply air for combustion or do you think I'll still have to open a window? My thought was that this would be excellent backup heat in the event of power outages and if I add some duct work I can transfer some of that analog heat to other rooms.

Below might be helpful, but who knows if Elite expects an ICFM4 infiltration input. +1 on their ACH values appearing to be too high. A guess is about 1/5 of what they used. It's unlikely that a typical ACH natural value (used for seasonal load) is appropriate for entry into the software.

https://higherlogicdownload.s3.amazonaws.com/ACCA/c6b38bda-2e04-4f93-bd51-7a80525ad936/UploadedImages/Infiltration%20per%20Blower%20Door%20Test%20Oct2016.pdf

I would like at the SpacePak Split Inverter Driven system, Jaga fan coils for cooling/some heating, and Jaga radiators/floor heat for heat.

Design the system on outdoor reset, use a max temp of at most 120 deg (or lower if possible).

Hi Ryan,

Really appreciate your feedback. I had to do some research on the SpacePak to understand what they were. This is a very similar system to what they were suggesting and in fact, the mechanical designers had noted SpacePak as an option.

I think this would provide excellent comfort, however, I am concerned about the lack of local support and knowledge on this and that it would be more expensive than a standard propane boiler and hydronic distribution, whereas I am hoping to install something less expensive given my high investment in insulation and windows.

I love the concept but have to find a way to reduce cost and I am thinking that the best path at this point is going to be the outdoor air-source heat pump with an indoor air handler and ducted distribution. The air handlers allow for a resistance heat accessory that would cover me for those times when it gets polar vortex cold.

Thank you for your time and thoughts!

As this conversation continues about the accuracy of the heat loss calculation, I did confirm the following from the energy consultant:

--

The load calculation that was performed was not strictly Manual J, we used the CLTD method and incorporated the Manual J guidelines/ properties. We used this method because it yields more accurate results.

--

I am trying to find my way through this with limited knowledge, but all of my decisions downstream of the load calculation depend on having really accurate calcs. I would much rather install a simpler and more efficient heating system if we can get by with it. The air-to-water system they proposed would be a very costly heating system.

Akos made some great suggestions above, see: "For heating, look for any of the hyper heat units that are rated bellow -20f. Once the heat load is sorted out, my guess you can heat the whole place with a single high static ducted unit (Zuba, SkyAir, LG red with VAHU)." ... but I am still trying to figure out what my next step should be to confirm the load and then design an air-source heat pump heating system that I can depend on, without really having the knowledge to select units, plan ducting, etc.

Does anyone have knowledge on how to do this, offer services to help with this or can steer me in the right direction?

You could use Rhvac Online or CoolCalc to do your own Manual J. Not hard if you have all the input numbers.

Design your kitchen ventilation for powered close-to-the-range makeup air - otherwise huge infiltration loads throughout the house are likely correct. Similar for a vented clothes dryer.

Be aware that many heat pumps will shut off at temperatures you will see. This complicates the design.

I would have them run the calculations with realistic air leakage numbers and correct design temperature. If the model is correct, once the inputs are fixed, it should give you a reasonably accurate estimate.

Assume you can hit around 1ACH50 with a reasonable care on a new build, you can guesstimate your ACH natural based on the info here:

https://www.greenbuildingadvisor.com/question/what-is-n-factor

Looks like you are in Zone 2 with a 2 story structure, so it should be around ACH50/14. My guess this will be significantly less than the air infiltration number they used.

As a ballpark looking at their report, about 30000 BTU of their loss calculation is from air infiltration, with the -25F design at is around 308CFM air leakage. In a 3000sqft conditioned space with 8' ceiling so 24000 ft^3, that works out to 1.29ACH natural, converting that back to ACH50, at is around 18ACH50. That is the air tightness of a century old balloon framed house with single pane windows and no insulation, not a new build. They are assuming your place will leak like a sieve.

Once the load calculation is fixed, you can start selecting your HVAC equipment. Your HVAC designer can do proper sizing of the ducts and registers based on the equipment selected the load calculations above. These steps are covered in Manual S,T and D. You want to ask them to provide these outputs for you.

Any HVAC engineering company should be able to this design for you, the biggest issue I've have found is getting them to input correct parameters into the energy modeling to not oversize everything.

Thank you!

Regarding their report showing 30,000 btu of the loss calculation being from air infiltration, it should be noted that the report does include the garage and they have an ACH of 6 for the garage, which is probably realistic. So, it the 30,000 you're mentioning largely from just the garage? That would seem plausible.

The entire report shows a load of 128k and the house alone is 52k of that (leaving the rest from the garage). My intent is to have them remove the garage from this calculation and then we'll plan garage heating separately.

Just want to be armed with information so that I can somehow communicate to them that it is clear that the report is inaccurate...

I think even if the 30,000 btu you cite includes infiltration from the garage, the fact that it equates to 18ACH50 is still relevant since they have input 6ACH50 for the garage airtightness.

Akos is on it - Look at room 7 (living room) on page 20. Of the 5895 Btu/Hr heat loss, 4200 comes from leaks. That's 43 CFM of air leakage at -25 design temperature - that's like a bathroom exhaust fan running, presumably in every single room. Once they tighten that up, you'll have a solid manual J.

If you look at the summary, it has infiltration loss at 96,388 BTU, even if that is for both garage and house, it is still silly high.

In the charts, almost all the rooms have around 70% of their loss from infiltration. In a well sealed house, this should be closer to 2% to 10%.

Make sure they also fix your design temperature. Since you'll need to install strip heaters, there is no reason to oversize your system for polar vortex days. For the rare time the system can't keep up, the cost of running the strip heaters will be made up by efficiency improvements the rest of the year.

Hi Akos, I appreciate all of your time.

I am preparing for a call with them and want to make sure I understand how you're making these calculation estimates.

For example, I've attached a screenshot of the living room snippet from their report (page 8). We've got a 254.4sf room with a 10.13 height (includes floor system). That's a volume of 2,620cu ft.

In pulling calculations from another GBA post, it sounds like I calculate load using this formula:

[delta-T] x [ACH(actual)] x [volume] x 0.018

The delta-T they're showing [I think] is -25 to 70, so 95. They're also showing their calculations at 1.1ACH.

Do I plug in 1.1 into that formula in place of [ACH(actual)] or do I need to get my [ACH(actual)] from somewhere else?

We're targeting 1.0ACH50 for the building (though they inaccurately used 1.1ach50.

Additionally, I see on the living room load summary, they show Heat. Infil.AC/hr at 42. Does that mean that it is showing 42 air changes per hour? Is that the same as 42ACH50?

Lastly, where should we be pulling the design temp from? I see -16º in Ashland in the "Design Temperature Limit Reference Guide (2019 Edition)" from Energy Star and using the ASHRAE site for our location, I am unsure which number to use as their tables list a variety of numbers. I attached a screenshot from the ASHRAE site.

Really appreciate everyone's help. Learning a lot here.

I think that 1.1 they show is the ACH number not ACH50. So that works out to around 5000BTU for the living room which is pretty close to their number of 4200BTU.

If you are targeting 1ACH50, that ACH number in their input should be ~0.07.

If you look at manual J inputs, using above 1ACH is for a loose building.

This very well could have been that they decided your place needs a 150000BTU boiler to heat and fudged to numbers till it came up with that. This is unfortunate but not uncommon.

For design temperature I would use the closet weather station with similar climate. Sometimes you get local microclimate that is colder, in that case you can look at historical data.

A heat pump with resistance backup sized even for 90% design temperature will heat the whole place as well as one sized for 99%. Most likely the operating cost between the two options is noise.

I'm planning a house similar right now in Alberta. When I had the my hearing system calculations done they had to follow the CSA standard which uses "present" air infiltration. You then have to size your active heating system to meet this as a minimum as per code. But the engineer admitted, most buildings only require about 60% of the numbers he provides.

Digging into this I found it to be 3.57ACH50. And some of his allowance are higher than what I believe I will build to. I also plan on building a tight house.

Using my house as an example. If I model to 1.5ACH my load is around 22000btu/hr using 3.57ACH it's 27400btu/hr. The number my study came up with. 36425btu/hr. 60% of his number is almost be exactly 22000btu/hr.

I have a very open concept 90sqft walkout basement bungalow and have extensively researched the heating systems. I am also trying to keep it simple as this a secondary cabin and won't be there for maintenance all the time. But a single head minisplit with an electric air handler/ furnace seem to be my best bet. 1 it meets all the code requirements to move fresh air into the bedrooms and kitchen from my HRV, it can circulate the air from the wood stove when we are there and it is a simple robust back up if the minisplit his it's cold temp shutdown.

Good luck and ask questions if you don't think something is right.

Also I've been using Hot2000 to model my house,. I believe it's the Canadian version of Beopt. It's worked very well for me and my model of my primary house is bang on compared to my ecobee and bills

Everyone, thanks for your help thus far! I am finding my way through this. First, I have confirmed that Wisconsin does indeed require us to use a design temperature of -25 even though the weather station in Ashland, WI uses a -16 99% design temperature. Scan attached of code requirements.

With your help (special thanks to Akos), I was able to provide the resource to convert their 1ACH50 to a proper ACH(nat). I learned that they have their "engineer in training" working on this project and there were some misunderstandings which ultimately ended in miscalculation.

I am awaiting an updated room-by-room load calc but in the meantime wanted to start assessing options for the most cost effective and energy efficient heat system for the house. I expect the load to be 30k-36k btu/hr at the -25º design temp. That design temp is lower than our 99% design temp, so bare that in mind.

---

Akos had suggested the following:

For heating, look for any of the hyper heat units that are rated bellow -20f. Once the heat load is sorted out, my guess you can heat the whole place with a single high static ducted unit (Mitsubishi Zuba, Daikin SkyAir, LG red with VAHU).

Might be simpler for ducting to go with a separate zone for the 2nd floor, something like a 12000BTU ducted unit (ie ARU12RGLX) can easily fit in the back of the closet.

Most ducted systems can take a resistance strip heater as an accessory. These are a very affordable way to add backup to your system. Just make sure the strip heater is configured properly and only come on when the unit can't keep up.

---

How do I sort through these units and find which ones have proper capacity at the lowest temperatures possible?

What am I looking for to get proper heat to all of the different rooms of the house? The main space is one large room but all of the bedrooms are separate. The basement is separate as well.

How do these units get zoned? Or do they not get zoned separately? If not, how do you ensure comfort in each separate room? What are the differences between single-zone and multi-zone units?

They're recommending a Carrier Infinity mini-split if I go the split route because it is much better performing at cold temperatures than competitors. Any feedback on that?

Thank you as always.

Best place to search is here:

https://ashp.neep.org/#!/product_list/

Look for units that have good maintaince capacity at 5F, most hyper heats will deliver 100% of their nameplate capacity at 5F and 80% capacity at -15F.

This is probably in the ballpark, maybe upsize to the 3 ton unit:

https://ashp.neep.org/#!/product/34523

http://enter.mehvac.com.s3.amazonaws.com/DAMRoot/Original/10006\M_SUBMITTAL_PVA-A30AA7_PUZ-HA30NKA_en.pdf

You'll have to do a bit of digging and lot of reading about specs. Most of the engineering data for these is buried somewhere on the manufacturer's page ie:

http://www.mylinkdrive.com/usa/M_Series/R410A_Systems-1/R410A_Outdoor

Fujitsu, LG, Daikin are not much better.

Since your actual design temp is around -16F, I would size the unit for that and make up the extra to the -25F with heat strips. The above unit can take a 10kW heater (34000BTU) which can probably heat your house even without any help from the heat pump.

Zoning is a squishy topic, usually best avoided as it adds a lot of complexity. With modulating inverter units is possible to do a bit of simple zoning. What you do is size the feed to a zone to oversupply the zone a bit, say 120% of required flow. Install a zone damper on the feed but adjust it so that it doesn't close all the way but limits the flow to around 75%. You can then wire a standard thermostat to drive this zone damper without any fancy controls. The air handler will easily modulate around this but of flow and pressure change.

With a multi story structure, sometimes it simplifies ducting to have a 2nd air handler on the upper floor, this saves you running ducts through the main floor plus it gives you zoning and a bit of backup. Important item there is you want each air handler on its own outdoor unit, don't let the HVAC folks talk you into a multi split, these are hard to get right and even then tend to be less efficient than one to one pairings.

The Carrier units are rebadged Midea units (I'm installing one of the 18k ducted units). These are pretty good, they tend to deliver 70% of their rated capacity at -22F. The only issue is these are slim cassette units and don't look like standard air handlers, your HVAC installer will most likely charge you extra to install it ('casue a duct adapter is hard to build').

I am digging in deep and creating a spreadsheet to list out the lowest temp outputs that they publish. You're right, it is a bit difficult to get this info as it is buried deep.

From a very high level, what you're saying is that I am not looking for a multi-zone unit like these: https://www.mitsubishicomfort.com/products/outdoor-units/multi-zone-cooling-and-heating? This is because they're not as efficient and it becomes complicated?

So am I correct in saying what I am looking for is a single zone unit? Then, the zoning is done through the use of zone dampers rather than a thermostat connection back to the unit itself?

When you say air handler are you referring to the "indoor units" (ie: wall mounted, horizontal ducted, cassette, etc.)? Or am I only looking for none of those and only a "ducted air handler?"

Is there a limit to the ductwork you can run when using one of these VS. a traditional furnace? I am trying to get the outdoor units where they can reach the inside of house and then feed all of the rooms (one or two outdoor units only). If I understand correctly, you have an outdoor unit and a line set going in to the air handler, then the duct work is off the air handler and that is all there is to it, correct?

I don't have any space above the 2nd floor to site anything from above, but I do have open web trusses above the first floor that could be used to move ductwork. Finding a place for anything but a wall or ceiling mounted unit could be tricky since our mechanical room is in the basement.

After lowest operating temps and maintenance of btu output, then what is most important? COP? HSPF? SEER?

Thank you!

To complicate things a little, having the lowest operating temps and output at low temperatures isn't always the most efficient or important since you will have backup heat. Mitsubishi, Carrier and LG have engineering manuals that give the outputs and COP in 5 degree increments - the non-hyper heat models seem to generally outperform them efficiency-wise, which over a whole winter may make up for the hit you take at sub zero temperatures. What's important is matching the climate's temperature distribution and your heat loss.

In terms of the air handler uncertainty, either a multi-position or a horizontal ducted unit would work. The multi-position ones are just bigger in size/capacity. The multi-position air handlers are furnace replacement options, so no limitations on the ductwork, it just uses slightly lower temperature air so you need a little more air volume.

Do you know what HVAC brands are in your area? That may narrow your options a bit to make this easier. For instance, Mitsubishi has searchable Diamond rated installers, I think most manufacturers are similar.

"From a very high level, what you're saying is that I am not looking for a multi-zone unit like these: https://www.mitsubishicomfort.com/products/outdoor-units/multi-zone-cooling-and-heating? This is because they're not as efficient and it becomes complicated?"

Correct. Multi splits generally have much lower modulations and in most cases COP. Without sizing them just right, there is a good chance of getting significantly lower efficiency than spec sheet implies. This is usually the case in the one wall mount per room type of setups that a lot of mini split installers push.

What you want is each air handler to have its own outdoor unit. These are simpler to get right and even if oversized, the efficiency is generally not effected.

"So am I correct in saying what I am looking for is a single zone unit? Then, the zoning is done through the use of zone dampers rather than a thermostat connection back to the unit itself?"

Yup. Always single zone unit. If you want more independent zones add another unit, that is one air handler plus outoor unit.

The zoning I described above only works if you need a bit of extra control, just enough to adjust the temperature in an area but not cut heat or cooling completely off. As long as you the overall flow is not greatly effected, you can do it with a simple zone damper+thermostat instead of the fancy zoning kits.

The unit I linked to is pretty much the same as a standard furnace. Correctly sized you can have very long runs of ducts without issues. The only difference between this and a standard furnace is the air temperature is much lower so you need larger ducts to deliver the same BTU of heat.

The only connection between the outdoor unit and the air handler is the refrigerant lines plus a small power feed. Most can handle pretty long distance in the order to 75' to 100' between the two.

The ducts than connect up to your air handler and feed rooms as needed.

The Fujitsu unit I mentioned earlier (ARU12RGLX) can be mounted vertically, so all you really need is a 3'x1.5' space in a back of a closet. These are lower pressure units so you do have to watch the ducts a bit, but should be no problem to run them through your floor trusses to rooms as needed.

I would avoid any wall mount or ceiling mount units for a new build. These are maintance items as the blower and coil needs periodic cleaning every 4 to 5 years. A ducted air handler with a good intake filter will stay pristine for many years.

In almost all cases sticking to a single air handler with ducting to all the rooms is the lowest cost option.

If you are in a land with muggy summers, the important item for that type of install is a largish return near the ceiling on the 2nd floor, don't skimp on that. If you go with two air handlers, this is not an issue as the return of the 2nd air handler will already be at the right location.

Once you find something that works, your most important item is local support. COP, HSPF, SEER are all fun to look at when doing energy modeling, chances are that any well sized and installed hyper heat unit will cost about the same to run. Don't get lost in the weeds chasing 1% incremental gains here.

One item I forgot to mention, since you are in snow country make sure to get a unit for pan heater. For some this is an accessory, so make sure it is ordered.

Also watch where the outdoor unit is mounted. You never want it mounted to wood walls, only to masonry, or even better ground mount. Make sure the unit is raised above the max expected snow fall and protected by an overhang. Keeping the unit out of the wind also helps with defrost and wintertime efficiency.

Hi Akos,

All of your help really got me going in what feels like the right direction. I've research equipment and it seems that likely the best combination is your original suggestion–the Mitsubishi P Series https://ashp.neep.org/#!/product/34523. Best capacity maintenance from 47º down to 5º, good subzero operation, reasonable COP, electric resistance accessory, pan heater, etc. most of all, I have a local installer that is very familiar with these units and feels like the combination of this and an air handler would be a great setup.

I am waiting on an updated Manual J, but I expect that the 3-ton unit will fit the bill.

All that said, the HVAC contractor indicated that he would expect this system to be very similar cost to a gas propane hydronic system. I received a quote for a Lochinvar boiler and in-floor heat throughout which was $32,000.

Doesn't that seem excessively high for a heat pump matched with an air handler and more traditional ducting?

It should be noted the LP boiler proposal included range vent, bathroom vents, dryer vent, gas supplies and make up air supply.

Either way, it sounds like I could still expect to pay 30k for a system like this. Does that align with your own experiences?

Every flavor of Mitsubishi quote for a ducted air-handler I received (2 ton & 3 ton, P series & M series, Hyper heat &. not, backup heat included/excluded) was <$10k, but conditions vary. This excluded installing ductwork, but included furnace removal and some minor duct modifications. If you haven't already, look up Mitsubishi Diamond installers in your area.

fyi, I'm in southern Ontario so prices will vary but it seems like Canadian prices are usually a bit higher so I would be a bit surprised if costs were that high for you. I just had a 36k Mitsubishi hyper heat installed that has three indoor connections, a wall mount, one way ceiling cassette, and a low static ducted and it cost me $~20k for everything (tax not included). Previous to that I had two quotes to install a 42k Mitsubishi Zuba Central that included installing all of the duct work (in an old home that had none and was going to be a challenge!) and they came in at $23k and $24k. I previously had looked into a air to water system and for my set up (a bit of a retofit that included some fan coil radiators) it was going to be around $35k.

The hydronic options seems to be in the ballpark. The heat pump is way on the high side. The Zuba units are not cheap, but also not that expensive, based on the price I'm guessing the guy wants to install the hydronic setup and doesn't want to deal with the heat pump. Since the heat pump unit is about $4000 above a standard furance+AC, it should be much less than $30k to install.

You can try to split the job up and have them quote the duct install and heat pump install separately. This tends to get it out of magical price territory and into more realistic cost plus labour.

Are you opposed to ductless units? With AC less of a concern, this may be a much simpler option.

In Michigan (Zone 5) I heat my 2400 sqft home with one 15k Fujitsu floor mount on the first floor. Downstairs is 70 and upstairs bedrooms are at 65 F in subzero temperatures. I am installing a 12k ducted unit upstairs, but for cooling purposes.

I would consider putting one ductless head on each floor for heat, closed bedrooms may be a few degrees cooler. Because you are going to be using electric resistance heat when it is really cold anyways, you could put a cove heater in each bedroom.

You would still have AC in the open area on the first floor and hallway on the second floor with some dehumidification, but not directly to the bedrooms.

Hi Kyle, not opposed but it seems that I might be able to find a system that gets me the best of both worlds. I am mildly concerned about the amount of solar glazing making the house warm in the summer or shoulder seasons.

This heat pump route with indoor air handler that has been suggested seems to be a pretty good way to go since I can get the distribution needed and add resistance heat as an accessory to the air handler. That simplifies things considerably and keeps me operating at a good efficiency for the overwhelming majority of the heating system.

Hi Michael,

I currently have a boiler w/ baseboard heat, not my cup of tea. It is comfortable heat and nothing more. I wanted central air, & to be able to do whole house filtration, humidification, dehumidification, and air purification/UV lights if I desire. I can't do any of those things w/ baseboard heat. It's all but useless to me personally. I also run a wood stove.

As a sheetmetal worker, I decided to do a ducted Mitsubishi VRF hyper-heat system, w/ zone 1 for the main floor & basement, zone 2 is a single floor unit off the heat pump for the bonus room above the residence. My home is a similar size.

I then did a 2-zone mini-split w/ a wall unit in the garage and a 4-way ceiling cassette in the bonus room above the garage.

Just food for thought so you can see what other folks do.

Thank you for the feedback Renovations102.

I don't know a lot about what is available with ducted HVAC, as you mentioned whole house filtration, humidification, dehumidification and air purification... Would whole house filtration provide something different than an ERV is ultimately providing? I can understand the humid/dehumid advantages, especially in a tight house.

Is all of this still kept separate from the ERV system?

Thanks!

Hello all,

The mystery has been solved. Now it is time to select equipment and get designing the ductwork.

The total load is 26,749 btuh at the -25º design temp for the 3,198 square feet conditioned space. The summary can be seen on page 16.

Does this look and sound more accurate?

With that, I think the unit that Akos had previously suggested would be well matched. Here is the 3 ton unit, which, in theory should be a little oversized allowing for more capacity at lower temps, right?

https://ashp.neep.org/#!/product/34527

Thank you for all of your help thus far. Please let me know if any of you have additional feedback as I work with this same mechanical design firm to design the ductwork sizing, etc. I could just take this to contractors at this point but I'd like to have something that is biddable since costs are varying wildly. I want bids to be apples to apples.

Thanks!

The equipment costs on a Mitsubishi PVA unit are quite expensive. I would bet you could get two smaller Carrier (rebranded Midea) units at the same cost. This would give you two zones and you might save on ductwork as well. I think you will be happier with the upstairs on its own zone.

That is much better, the design load now matches what you are building.

Looking at the specs of the 2.5 ton and 3 ton unit they are close enough that either one should work. Both should cover your real -16F design loads without aux heat, so the heat strip should only ever be needed for backup.

Kyle does have a good point about material cost. If the installer can supply you with the Carrier ducted units, say a 2ton for the main+basement and a 3/4 ton for the 2nd floor. They have much better modulation range and should cost less.

https://ashp.neep.org/#!/product/33268

https://ashp.neep.org/#!/product/36663

Thanks Akos and Kyle!

I can't find any information about the Carrier unit being compatible with a electric heat accessory. Is this something that the air handler itself has to have or is it something that is an accessory added to the ductwork?

Also, the Neep.org links show the indoor unit as this: https://www.carrier.com/residential/en/us/products/fan-coils/fmc/

Am I correct in saying that that is not the indoor unit I'll want since it looks to be intended for ceiling installation? I'll want a fan coil style like this:

https://www.carrier.com/residential/en/us/products/fan-coils/fv4c/

Is that correct or would I be looking for different air handler styles for the basement/main vs. the 2nd floor.

Thank you!

I've not dug into Carrier's offerings to be able to help too much. The cold climate split units are made by Midea, who does not offer a standard air handler, I don't know which outdoor units the FV4C can work with and if they are good down to -20F.

The Midea mid static cassettes can also be mounted in vertical orientation, so it can work the same a standard air handler. The blowers on the 18k+ units can do up to 0.55" external static pressure, which is less than the Mitsubishi PVA at 0.8", this would mean the ducting cross section area would have to be upsized by about 15%. I can be easily be made to work. Not a "standard" install, so you will probably get pushback from HVAC installer.

The documentation is not that great about available accessories, I see some of the Carrier units can be ordered with a strip heater, you would have to check with them directly. You can install a strip heater to any ducted unit but it will need a separate thermostat to drive it and won't integrate as well as the factory unit. You can also spec the a slightly higher capacity unit that can carry your place at -25F and not worry about the strip heater.

I don't see any documentation either, but I would assume the installer could put in an electric duct heater. The tables in the manual show heat outputs down to -22F, so I think electric heat backup might not gain you much on these units. With a 3/4 ton upstairs and a 2 ton downstairs, you would still have ~23k btu/hr at -22F according to Carrier's table. You can find the product data on Carrier's website.

The 3/4 ton and 1 ton unit can only handle 0.2 in wg, so if you go with either of those make sure this is considered in the duct design and that the installer actually follows the duct design. The bigger air handlers can handle higher static pressure and are more forgiving.

Personally, I wouldn't include the basement until you actually finish it. Trying to cover it with the first floor unit is possible, but not easy to design correctly. I would just put a ductless head down there when you do finish it.

Thanks Kyle and Akos.

The mechanical designers are looking at the Mitsubishi and Carrier units and will be circling back with their recommendations.

They did have some questions on our ERV system, however, I haven't heard of the comfort issues they're describing in their inquiry. Can you or anyone advise on their notes regarding approach to the ERV system:

---

"Regarding the ERV system, I would like to provide you with some considerations.

When possible, it is best practice to have a completely dedicated ERV supply and exhaust duct system. In cold climates this can create some issues with regard to occupant comfort and energy consumption.

Example, during the winter, if the dedicated ERV supply is not conditioned it will be too cold and cause comfort issues within the home. Your system would require an electric resistance heater in the ERV supply to temper the air to 72 degrees, resistance heating elements though can be costly to operate. If you would like this we can certainly design the system this way.

What we recommend is to have a hybrid or "exhaust-ducted" ERV system. This is where they are dedicated exhaust duct for the ERV but the supply duct from the ERV goes straight into the main trunk of the return or supply for the air handler. In this case the ERV supply air will be conditioned by the heat pump coil and be distributed through the air handler supply ducts. Another benefit to this system is that there will be some material and labor savings because the ERV system will only need to have dedicated exhaust ducts rather than both supply and exhaust ducts.

Lastly, high performance homes and green buildings are many times built with a central return grill and then transfer grills or door undercuts to each bedroom and bathrooms to act as the return path for the air. There is a benefit in cost savings because there is much less return ducting needed. But there are also some disadvantages. We are looking at this as a possible design option.

Please make comments regarding the ERV system and return duct system if you have any."

Any thoughts on their recommendations here?

Thanks so much! You guys are really acting as quality assurance on my HVAC plan. We need a "send 6 pack of beer" feature here on GBA.

I agree with both of their recommendations. Going with ducted mini splits helps in both respects. Because the air handlers will run almost continuously, this will help supply continuous fresh air distribution to all rooms and avoid getting “cold” fresh air. Yes, dedicated is better from a guaranteed cfm per room standpoint, but I like the hybrid design better with ducted mini splits.

Ducted mini splits also typically have much lower air flow rates than conventional furnaces making it much easier to avoid pressure imbalances with jumper ducts. Just ensure the central returns are over sized with at least 2” thick filters to avoid excessive pressure drop.

This topic has come up before. General consensus is the flow is low enough and if the fresh air register is correctly placed (near the ceiling, blowing along the ceiling and away from people) that it doesn't matter.

You are in pretty cold climate, so it might be more noticeable though. A 25CFM fresh air feed would create about 400-500 BTU of cooling in a master bed when -10F outside. Not a lot but you probably feel it if you put your hand directly in font of the register.

At home I have something similar to the approach your HVAC designer suggest. In my case there are stale air pickups in the bedroom and fresh air is delivered through a single register near the peak of the ceiling in the living space. I find that it works quite well, the air in the bedroom never feels stale. Feeding the fresh air feed to the intake of the heat pump would avoid any temperature issues completely.

Whenever tying into HVAC, try to go for one of the auto balance units, less chance of blower speed changes effecting the ERV flow rates. The Panasonic unit might be on the small side for your place, the Broan/VanEE/Venmar AI units are larger although less efficient. The Zehnder ComfoAir Q350 TR might be a good option, it does get pricey if you need a lot of ducting.

Hi Akos,

We continue to make progress on this. Both our HVAC contractor and the designers were more comfortable with the high static Mitsubishi approach, so that is where we're headed.

If we need to pivot, do you or anyone you know on GBA do system design? I don't want to continue working with this company as they don't seem to be on the cutting edge as I thought they would be.

As for the above comment about Zehnder, I received the following response in regards to integrating with the other ductwork.

--

Our Zehnder ERV can be used as you are describing. I would not use the Q series because the mass air flow sensors and fans will be attempting to compete with the air handler fan to maintain a balanced air flow.

I would recommend one of the CA 350. 550 or 200 units, depending on capacity.

The simplest way I can describe the major flaw in this configuration is:

With the Zehnder air distribution: an extract register is continuously removing odors, moisture and chemicals from the bathrooms and kitchen( sources of pollutants and moisture) and after the enthalpy exchanger in the Zehnder unit supplies air to the bedrooms( where the C02 levels are the highest. This supply air then goes through the rooms it supplies, out the door, down the hall, through adjacent rooms picking up pollutants along the route and enters the bathroom and kitchen to complete the cleaning cycle. Along the way, the temperature and humidity are always trying to achieve balance.

A continuous strategy is alway cleaner, quieter and uses the least amount of energy compared to a traditional furnace and intermittent bath fans.

An acceptable compromise would be to have an extract register in each bathroom, the kitchen and utility room. The supply air could be sent in a single duct into the return side of the central heating/cooling system.

This is not ideal, but a less costly alternative that preserves the function of point specific extract registers. This could be achieved with traditional warm air ductwork or the Zehnder ComfoSystems products.

--

Do you have any thoughts on the Q-Series?

Do you have any thoughts on their concerns about shared ductwork? They cite a traditional furnace, so they may not fully appreciate the advantages of this approach given the use of mini-splits.

Thank you!

Mike

The reason for the autobalance and the Q series is precisely because it needs to fight the air handler to maintain balanced flow.

If the return ducting is not very restrictive (less than 0.1" WG drop), you can go for a fixed speed ERV unit as that amount of pressure change won't drastically effect the balance of the ERV. Autobalance is still simpler, it is also harder for the installer to mess up commissioning.

I'm not sure what they are getting at with continuous VS intermittent ventilation.

A modulating heat pump runs the blower fan 24/7, if the supply duct is connected to the HVAC return, you'll get continuous ventilation. The challenge with this type of setup is that it is hard to meet ventilation needs of smaller rooms without a lot of exterior walls as the heating flow rates are very low. You have make sure the rooms get sufficient CFM even when the HVAC is running at low load.

Dedicated ducting for the ERV is always the best but the semi shared ductwork (dedicated stale air pickups, fresh air to the HVAC return) setup is a decent compromise (I'm doing it for the current project), the only thing I would do is a small stale air pickup in the master bedroom. Besides guaranteeing air changes in the room independent of the furnace, it also comes in handy after taco night.

Also make sure that the bathroom pickups can do at least 50CFM on boost. Usually this means only connecting the ERV to the most used bathroom and having standard exhaust fans for the rest.

Hello all,

After the Manual J being updated and me providing the mechanical designers with the feedback from the GBA experts here (thanks!), they've come back with the following.

Here's the cliff-notes:

- The Mitsubishi unit (PUZ-HA36NKA) that I (Akos originally) had suggested would be great but it is commercial and will be more expensive.

- They suggested other (SUZ-KA36NAHZ) Mitsubishi units that they felt would do the job but would be 25% less expensive

- They believe that heat strips to meet full demand or a separate backup is essential to appease the inspector about meeting the -25º peak load.

- They didn't feel confident the two Carrier units would be appropriate due to static pressure limitations per size

- They suggested a new Carrier unit that we hadn't previously discussed (25VNA436) or their indoor gas furnace (59MN7B) combined with the heat pump.

Here is the full response. If you have the time, I could really use some feedback on which track might be best or if there are other questions and push back I should be providing. They present a lot of considerations.

-----

The heat pump you chose would definitely work well for your home heating and cooling system. A heat pump paired with an indoor air handler and ducted heat distribution system will definitely provide for a comfortable home. We will also want to add an electric heat kit to the air handler if we go all electric.

Mitsubishi Equipment

That unit you chose (https://ashp.neep.org/#!/product/34527) is an excellent choice but it is a P Series unit which is a commercially built product and costs roughly 25% more. The unit we are looking at is of very similar size but the M series which will be cheaper. I spoke with a Mitsubishi rep who told me this information about the cost difference.

The exact combination could not be found on the NEEP site but here is a link to the submittal information for the unit.

http://www.mylinkdrive.com/viewPdf?srcUrl=http://enter.mehvac.com.s3.amazonaws.com/DAMRoot/Original/10006\M_SUBMITTAL_SVZ-KP36NA_SUZ-KA36NAHZ_en.pdf

Indoor Unit SVZ-KP36NA

Outdoor Unit SUZ-KA36NAHZ

A few things to note regarding this system,

First, the manufacturer states that it is possible for the unit to go into protection phase at air temps of -18 and completely turn off. If this were to happen the electric heat kit would then kick in and would be able to provide complete back up heating for the entire load.

The heat pump is rated to a capacity of 37,000 Btu/hr at 5 degrees and 29,600 Btu/hr at -13 degrees. In the case where the heat pump cannot provide all of the needed load for the home, the electric heat kit will kick in and provide supplemental heat. The heat kit is two stage with two 4kw resistance heaters so it is capable of providing 13,648 btus of supplemental heat or 27,297 btus as complete back up. It is possible that the electric heat kit will never run but it will be required so that the code official can see that the load will be met at the -25 design conditions.

If you are planning on having a backup generator tied to the heat pump and air handler, keep in mind that if you also have the electric heat kit tied to the generator it will add another 8kw needed capacity on the generator.

Also, if the generator will not be large enough to serve the heat pump, it could be used to run the air handler fan in conjunction with the use of the wood stove to help circulate the hot air around the home in the event of a prolonged power outage during the winter.

Carrier Equipment

When we did the system selection analysis on the carrier equipment we found the following.

First off, we looked at the possibility of utilizing two heat pumps for two zones of the house like you had previously stated. We also thought that https://ashp.neep.org/#!/product/36663 compact ducted unit could be a good option but after looking closer at the unit requirements and static pressure limitations per size we found that it is not possible to use this system because of the amount of static pressure that would need to be overcome because of the necessary duct work.

With that said, we have found two great options for one centrally ducted system to serve the whole home.

Both of them would utilize the 3 Ton infinity 25VNA436 heat pump. This heat pump is Carrier's top of the line heat pump. The heat pump is rated to operate down to -15 degrees and they say will operate further until around -20 where at that point may shut off for protection purposes. Based on the heat pump data, this will provide the complete load for the building, 27,768 Btu/hr, at 5 degrees and 22,280 Btu/hr at -3 degrees.

Option 1

Pair the heat pump with what Carrier calls their Fan Coil, similar to the Mitsubishi Air Handler, the fan coil would be FEANB003. This unit is also compatible with heat strips that can be added to the unit in 5kw increments. Two heat strips would be needed for complete backup heat.

Option 2

Pair the heat pump with Carriers indoor Furnace 59MN7B, size 060C17--14. This furnace comes shipped set up for Natural Gas but there is a kit to convert it to LP. In the case of this furnace, the source of supplemental heat would come from the propane burner.

The exact combination could not be found on the NEEP site for Option 1 or Option 2. I did have a Carrier sales rep send me the submittal information for these products and it is attached to this email.

The note about the generator applies to these options well but in the case of the furnace, the generator would just need to power the furnace burner and fan.

Please check out this GBA Article: https://www.greenbuildingadvisor.com/article/ducted-minisplits-in-my-conditioned-attic-part-2

It sounds to me like they designed the ductwork before choosing an air handler. It is definitely possible to make the lower static pressure air handlers work with the proper duct design. With open web floor trusses there should be ample room. My guess is they don't have experience with designing ductwork for low static air handlers and don't want to go down that path. Are they doing a Manual D?

I haven't looked at the specific Carrier heat pump they recommend, but don't doubt they have one that could work. I still believe you will be happiest with a separate air handler per floor so you have true zoning. It is possible to do this with the low static pressure ducted mini splits. The ductwork will need to be larger and special attention given to fittings with large equivalent lengths. A properly done Manual D will do this. A different strategy can be employed for low load homes like yours. Check out this link as well: https://www.nrel.gov/docs/fy13osti/57349.pdf

Generally if your hydro is around $0.10/kWh, propane heat would be about 1.5x to 2x the cost of a good heat pump setup. I would not go down the LP road unless there your local electricity supply is very unreliable.

So, staying within the heat pump realm. The SVZ-KP36NA / SUZ-KA36NAHZ should work just as well, specs vise it seems pretty close to the P series.

The Greenspeed units really start to fall off on performance in very cold climate, I think they are great equipment, just not the right for your design temperature.

I call BS on the pressure loss argument on the mid static unit.

I've successfully ducted an air handler rated at 0.15" WG (so 6x less pressure than the 24k mid static unit) without any issues. It really wasn't that hard, all fittings are standard off the shelf pieces and the ducts are not all that large.

For something that does 0.5", all you need is about 1 size up ducting from a "standard" furnace install, avoid some of the really ugly fittings that have huge equivalent length and use a filter about 2x size you would spec. If you have 12" to 18" trusses/I-joist for your floors, you have lot of space for bigger ducts, fitting them is a non-issue.

Reading through their response, it does sound like they are doing their homework, much better than lot of the HVAC installers out there, maybe not worth pushing them too much.

Thanks Akos and Kyle.

Simply put, do you guys think that the two Carrier units are going to provide enough better comfort, redundacy, etc. than the single Mitsubishi unit that I should push back on these guys and ask that they look closer at that? Or is the Mitsubishi unit totally worth moving forward with? Could we use 2 smaller Mitsubishi units?

We do have 16" open web joists for the second floor system but perhaps they're looking at the load transfer LVLs and thinking that it will be too difficult to get the larger ducts distributed? I attached our floor truss design and it seems totally doable.

Is there anything else that they'd be seeing that is making them think those mid-static Carrier units can't work?

If you think I should push for the Carriers over the single Mitsubishi and I'll sort of insist that they dig in deeper and look at making that happen.

Let me know. Thanks so much you guys!

Either system well set up will work, it comes down to your preference and what your installer is comfortable with.

Personally I would find the dual zone setup much easier to install, you don't need to run long returns and you can get away with much shorter runs to feed each room.

You can approach it a couple of ways.

Have an HVAC designer run the numbers on the two Carrier units and spec the ducting. You can than have your contractor quote on installing the units as per design. This gets any perceived issues with pressure loss out of the discussion.

You can also have him quote an SVZ-KP24NA SUZ-KA24NAHZ for the main space and basement and a PEAD-A09AA7 SUZ-KA09NAHZ for upstairs.

You have put a lot of thought and effort into the design, if it was me I would want two zones. If you have one zone with the thermostat on the first floor the upstairs will always be warmer, usually the opposite of what people want. With two zones you will likely find that the upstairs unit only runs on the coldest days and in the summer you only need Ac upstairs. Two units gives you this comfort.

However, if they are not comfortable doing a Manual D and engineering the ducting for mid static pressure air handlers, you don’t want them to guess wrong.

One compromise may be to drop the upstairs hallway ceiling and put an air handler there. Central return in the hallway and very short ducting to each bedroom and the bathroom. There should be no concerns about static pressure and it simplifies the upstairs ductwork greatly.

Hey Akos and Kyle,

I'd prefer not to drop the ceiling upstairs if possible since it is only an 8' ceiling. I assume that PEAD-A09AA7 would require that, right?

Can that be installed in the open web truss floor below or do you want the ducts entering those second floor bedrooms up high?

I also have that whole crawl space on the north side of the second floor. It is labeled "storage attic" in the drawings. Is there any way to feed the bedrooms from there like the attached drawing?

From a high level, what are the differences between the Carrier unit route and the Mitsubishi unit route? Are we just talking about the difference in static pressure and the size of ductwork? Other than that, they're pretty similar?

The Mitsubishi unit can only be mounted horizontally, so that tends to mean a dropped ceiling if you want to put it in the hallway. If I remember correctly your attic is inside your conditioned space, there it can be hung from the rafters and ducted to the rest of the house.

You won't be able to make large enough holes through the 16" LVL for ducting so you can't run them that way. The ducts can be either run in small bulkheads in the top corner of the hallway or building the hallway wall of the bathroom out of 2x6 or double 2x4 on flat over a 2x6 plate and running the ducting through the wall.

For returns on the slim units, I prefer to keep it simple and mount a filter grill to a short length of ducting that either directly mounts to the back or to the bottom depending on which direction the unit is facing. This usually means the outlets have to do a 180 bend before feeding some of the rooms. The extra bend is not a problem if done with metal ducts.

There is not much difference between the Midea (Carrier) and the Mitsubishi units. The PEAD does more pressure than the Midea 9k unit, with the short runs, I doubt it matters much.

Both 40MBDQ09--3 and 40MBDQ24---3 can be mounted either horizontally or vertically, which might make install a bit simpler.

Midea units tend to provide a bit more cold temperature performance and they are specked down to -22F.

I did a bit more digging on the Carrier units. Looks like their mini splits can also handle standard air handlers not just the slim ducted unit.

Looking at the specs paired with the both vertical fan coil and standard air handler. The COP numbers when paired with these are excellent (24k and 18k is way better than the rest).

https://www.shareddocs.com/hvac/docs/1009/Public/0C/38MAR-08PD.pdf

Since the smallest one is 12k, these would be oversized for the 2nd floor, but could definitely do the main floor and basement.

Akos,

I had never looked at the ratings with standard air handlers, but find it hard to believe their COP numbers are better for the standard air handlers. Might they not be including the power to run the air handler because it is not powered from the outdoor unit?

Hi Akos and Kyle,

We're just about there on this HVAC system!

One clarification from this last round... Either way, if I go with the Carrier two heat pump solution, I'll have to either drop the 2nd floor landing ceiling or fur out the bathroom wall to allow for ductwork, correct? You're saying we can't get all ductwork in the floor system?

From there, here is the design firms last response. Can you confirm that this is an accurate summary and then give me any additional insight on an appreciable difference about which will provide the most comfortable home?

Then, I think we're there and I'll make a selection and have them move forward with the specific design. Thank you SO MUCH you guys.

---

Two Heat Pump Solution:

After running a few different ducting scenarios for the upstairs compact ducted unit we found that it would be possible to use the compact ducted unit but it would have to be located in a dropped ceiling at the top of the stairs.

Advantages of Two Heat Pump Solution:

Better zoning control

Less air handler ductwork

Lower level unit could provide some heat to upstairs

Disadvantages of Two Heat Pump Solution:

Units would modulate more

Upper level unit could not provide heat to lower levels

More ERV ductwork

Would utilize the carrier heat pumps which are not great cold climate heat pumps

Would have lower Merv rating filter on the upstairs unit

Upstairs unit would be considerably over sized

Most likely louder fan noise

Advantages of One Heat Pump:

Units would modulate less

Would have one whole house duct system to circulate air as needed

Less ERV Ducting

Disadvantages of One Heat Pump:

More air handler ductwork

We would be happy to design either system.

Here is the floor system for your reference... There is one joist bay that doesn't have the LVL so ductwork could be run there.

Just want to make sure I understand the extent of the differences between what is required of these two different approaches, including how and where the ductwork has to be run.

If I am hearing you guys correctly, because of the size of the units, for our second floor we would have to go with a slim ducted unit. So the fact that they can work with a standard air handler doesn't matter for the 2nd floor, right?

If we went with dropping the ceiling for a slim ducted unit how far would the ceiling have to be dropped to accommodate?

Since the LVL doesn't run the full length of the house, you have one joist bay that is open that you can probably run all your ducts through. On a low static unit, a typical bedroom needs a 6" feed, so that can easily run through there. Since there will be more bends than a dropped ceiling install, that might have to be upsized a bit but should still easily fit with 16" trusses.

Also you don't need to loose height for a dropped ceiling for a ceiling mount. With a pitched roof, you can always increase the ceiling height in the other rooms by 12" and drop the ceiling in the hallway down to standard height. Nobody will complain about having 9' ceilings in a bedroom or a bathroom.

You can easily use a merv13 filter with a low static unit. All you need to do is upsize the filter grill a bit, which doesn't hurt anyways. A 20x25x1 merv13 filter will be less than 0.075" pressure drop at 350CFM you would see with a 9k unit.

ERV ducting is moot, you only need to run a single 5" flex up to the unit from the basement, that is a pretty simple to add in.

The right Carrier heat pumps are better than the Mitsubishi units in cold climate. Make sure they are looking at the ones OEMed by Midea not the Greenspeed units.

P.S. Probably too late since truss length can't be changed now, but a 3 ply of 18" LVL is seems oversized for that span, that could probably be 2 ply (or 3 ply 14").

Regarding the LVL and single open joist bay:

Would the duct work for the main floor be run up to the open web joists of the second floor and then vented through the ceiling or would that all be down down in the basement? The reason I ask is that everything would have to pass through that single open joist bay then since the mechanical chase comes up from the basement in that storage attic space via the closet below.

On the ceiling height: I had to switch the design to trusses to availability so now that is a flat ceiling that runs straight out to the front dormer wall. So it isn't just raising a collar tie. I am meeting with the truss company tomorrow and could look at raising that ceiling to 9' if that was the route you guys thought I should go.

The LVL is a 3-ply 16". I think it looks like 18" because of the low resolution.

So, to summarize, is sounds like the only disadvantages to the Carrier route are:

- Units would modulate more

- Upstairs unit would be considerably over sized

- Most likely louder fan noise

and the advantages of One Heat Pump:

- Units would modulate less

- Would have one whole house duct system to circulate air as needed

Can you help me appreciate what the real-life difference will be? It sort of sounds to me like both you and Kyle R. think that the Carrier route might actually be the better option but that either one would work just fine.

Should I just choose based on their comfort designing the system and which route my installers or more comfortable with or what should be the ultimate deciding factors between these two paths? Thank you!

The SVZ-KP36NA/SUZ-KA36NAHZ has a minimum turndown of ~14k BTU/hr. The 9k Carrier has a minimum turndown of 4.5k BTU/hr and the 24k is 6k BTU/hr. So the overall combined output of the two carrier units is actually less than the Mitsubishi. Additionally, you will likely only need the downstairs unit during heating season except for very cold days. Assuming you like the bedrooms cooler than the main living space. Also ducted mini splits are very quiet due to the low air flows.

The concern I have with one zone, is the upstairs may be warmer than the downstairs. Say you set the main level thermostat at 70 F, the unit modulates to maintain that setpoint. However due to convection the upstairs rooms are 72-73 F. The occupants would actually like the bedrooms to be cooler than 7o, more like 67F. With a standard gas fired furnace this is usually handled with a night time setback. However, with a right sized heat pump, you won't have the capacity to quickly heat up the house again in the morning, it may take most of the day.

Alternatively, with two zones...Downstairs is set at 70 F. The upstairs bedrooms are at 67 due to convection until the outdoor temperature drops below 0F. With an upstairs zone setpoint of 67, the upstairs unit doesn't even start running until its below zero, but it has the capacity to maintain the setpoint.

The opposite will be true in the summer when you will want to cool the bedrooms without freezing the downstairs. Now obviously I am just giving you numbers as an example (based on my own home before I went to a two zone mini split system), but the physics is the same. Warmer air rises. Your results will vary, but you can prepare for this by having two zones.

Throughout this process I think you can see that it is difficult to find a company to properly design an HVAC system, especially a mini split system. It is also difficult to find a qualified installer. Because of this I would encourage you to ask for a design that can accommodate either Mitsubishi or Carrier equipment so that you can get bids from more installers. The available equipment is similar enough that this shouldn't be a problem. The only major difference is that the Mitsu low static unit for the upstairs can't be installed vertically like the Carrier. Something to keep in mind.

Ultimately, whether you choose to go with 9 ft ceilings, install the unit in the basement, 1 zone or 2, it all comes back to cost vs comfort. It is difficult to give you definitive advice without knowing all of the costs. I am just trying to give you my advice based on my experience with my own home. 2 zones provides more comfort and should be workable in your design.

Not much more I can add to what Kyle said. Comes down to cost and comfort expectations.

For me, since the cost of the single zone Zuba VS two single zone Mideas is about the same, install cost should be a big higher but close, I would go for the two zone system.

Hi guys,

I've taken so much of your time. I am incredibly grateful for your help. Kyle said is right when he said "Throughout this process I think you can see that it is difficult to find a company to properly design an HVAC system..." It is like pulling teeth!

First, I want to summarize the two options for my own clarity:

1 Mitsubishi Hyper Heat Mini Split

SVZ-KP30NA & SUZ-KA30NAHZ (30k)

(They ultimately thought the 2.5 ton was better due to appropriate sizing, turndown, etc.)

- Safety cutout at -18ºF

- 2.5 ton output 32,000 @ 5º / 5,600 @ -13º (output at -13 degrees is 1,323 Btu/hr below the peak load at -25 degrees. It is likely that these 2.5 Ton units would be able to provide all of the heat down to at least -13 degrees)

- COP @ 17º = 2

- COP @ 5º = 1.75

- COP @ -13º = 1.7

2 Carrier Minisplits

38MAQB09R (9k) paired with 40MBDQ09---3 (slim ducted in 2nd floor landing ceiling)

38MAQB24R (24k) paired with 40MBAAQ24XA3 (air handler) or FMA4X2400AL (vert fan coil)

- Operates down to -22ºF, states “up to 69% rated capacity at -22ºF”

- 3/4 ton output 10,000@5º (max) / 8,350@-13º / 6,900@-22ºF / COP @ 5º = 1.91 / range 4,000~15,000 / HSPF 12

- 2 ton output 26,970@5º (max) / ~20,000@-22º / COP @ 5º = 2.10 / range 6,000~30,000

I did increase our truss ceilings to 9' to allow for a dropped ceiling in the landing if we need it. I had to order trusses immediately so I figured that at least leaves options.

After sending them feedback from our last round, i am catching the drift that they really think the Mitsubishi route is better and aren't concerned about the overheating. See below.

--

We would recommend the 2.5 Ton M-Series Ducted Air Handler System along with a zone damper with bypass and thermostat to control the upstairs, continuous operation of the ERV tied into the air handler ducting system, while also operating the air handler fan running on low speed continuously.

System matches the loads very closely

System will be continuously circulating air to promote mixing and air filtration

System has the ability to control the upstairs as a separate zone

Because of the continuous ventilation some of the cooling will actually come from the basement

2.5 Ton Mitsubishi heat pump has a higher COP at maximum capacity at low temperatures compared to the 3 Ton Carrier

2.5 Ton Mitsubishi heat pump has a higher turn down ratio compared to the 3 Ton Carrier

Other benefits have previously been discussed

Upstairs Zone Discussion:

We can easily add a zone damper to the upstairs with an adjustable bypass, controlled by an upstairs thermostat. Additionally, because there will be continuous ventilation in the home, it is not likely that there will be a large temperature difference between downstairs and upstairs.

--

This sounds to me like they're still comparing the specs of a 3 ton Carrier unit.