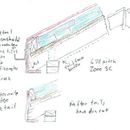

How will this 3 inch top deck, R21 below, Zone 3C Class A fire zone metal roof insulation perform?

Comments on this possible hybrid unvented roof assembly?

This is for a storage attic.

Zone 3C (Marine influenced)

6:12 Pitch. All hip roof.

Class A Wildland Urban Interface Fire Zone, California.

R38 local building code requirement.

6″ dimensional rafters, 4 or 6″ dimensional ceiling joists below.

That makes a stack of:

Solar panels

Metal Panels

Versashield

Peel & Stick

1.5″ RMax Ultramax (edged with pressure treated 2×4 on edge)

1.5″ RMax Ultramax (edged with pressure treated 2×4 on edge)

1/2 CDX Ply

Skip Sheathing

6″ dimensional rafters 24″ on center

R21 fiberglass unfaced

magic membrane

sheetrock

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

3" of RMax Ultramax only adds up to R17.4. How does that meet an R38 code min without insulation in the rafter bays? Oh wait- I see a scribble in the image indicating R21 fiberglass, (not mentioned in the layer stackup text in the post.)

R21 fiberglass is manufactured at 5.5" of loft, which does't fill a 6.0" deep rafter bay. And it's designed for 1.5" wide rafters, not 2" , so fitting it without bowing or buckling is going to require some trimming for width, and it would still leave the empty channels between the skip sheathing for air/fire to move.

With the skip sheathing it's better to use a blown fiber insulation to fill all voids, preventing thermal air (and fire) bypassing in the spaces by filling it with air-and fire retardent insulation.

Filling a full dimension 2.0 x 6.0" rafter bay would be good for ~R22 if 2.8lb-3.5lbs dense packed cellulose (which would make it to code min, if barely) and 1.8lb-2.2lbs fiberglass would be about R25.

Using cut'n'cobbled foam for the air dam/baffler over the top plates of the studwalls is a serious weak point from a fire hazard point of view. That foam will light off much sooner and burn quicker than 2x lumber. Fiber cement trim board as the air dam would be a better bet.

Thanks for the note on top plate foam baffle as a fire hazard. The RMax Ultramax has a fiberglass sheet, but still.

Maybe fiber cement board THEN frame out the cavity with magic membrane and sheetrock. Drill holes in the sheetrock and dense pack the entire mess. No foam.

Previously we had ember safe intumescent vents specified at the eaves, for a vented attic. However the eaves are hardly fire safe.

Hate fiberglass blown in, don't want to go there, or breathe that.

Or maybe thicker batts, compressed a little? Trimmed 1" first with a good knife?

Fire rated plywood rather than cement board instead of cement board, nailed to the rafter ends?

Do you have a detail from the metal roof mfg of how to install a metal roof thru 3" of foam?

You need a nail base panel to attach the metal roof to. see page 4 of the PDF to see a unvented nail base panel -- or a top layer of ply or osb http://cornellcorporation.com/docs/ThermaCal_Nail_Base_Roof_Insulation_Panels_Product_Brochure.pdf

For the metal roofers here the foam part is a standard detail. They just slap the foam down, slap the panels down, and use long screws. There's no secondary nail base above the foam.