Metal ceiling air sealing difficulty

Hi. I am in Zone 4a and building a pole barn shop. I wanted to use metal roofing tin as the ceiling but am unsure about air sealing tin roofing.

I thought I could use a good polyurethane sealant such as Tremco Vulkem 116 or BASF Masterseal NP-1 at seams, on edges where ceiling meets wall, and over screw heads. I would then blow in cellulose fiber insulation on top of ceiling.

Does this sound good, or are there some problems with my approach?

Thank you for any advice.

-Mike

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Mike,

Use taped 6 mil poly as an air/vapour barrier before hanging the metal ceiling. Then you don't need to worry about seams, screws, etc.

Malcolm, thank you!

I like it. Low budget is my first, middle, and last name. Can I use 6mil for wall air sealing as well? As shown in the following image, or even putting the wall 6mil next to the metal so I can blow in more wall cavity cellulose?

Thank you.

-Mike

Mike,

Poly continues to be used as a combined air/vapour barrier on 99+ % of all buildings in Canada. The main knock against it is that it precludes drying to the inside, but with metal as the interior finish you wont get any drying through it anyway.

Run a bead of acoustical sealant on the intersection between the slab and bottom plate. Tape all the poly laps, and make sure they fall on solid backing.

Malcom, I started reading about polyethylene air sealing and I came across this:

"When the same techniques were later adopted by American builders in places like Ohio and North Carolina, builders learned an important lesson: “Climate matters.” In hot climates or mixed climates where air conditioning is common, interior poly can become a condensing surface for exterior moisture during the summer. In many cases, the result was mold and rot."

If needed, I can change to plywood or drywall interior wall if this will be an issue. Please note that when the weather is hot, I will likely open the shop door.

Yes, any low-perm interior surface can become a condensing surface if you are cooling the interior. Plywood is a much better wall for a shop anyway as you can use it to mount shelves, tools etc. The problem is how to air-seal the seams if you don't have backing everywhere on a pole barn.

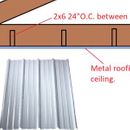

Ok then, rather than a conventional pole barn with girts around the posts, I will plan to frame between the 6x6 posts with 2x6 framing 24"O.C. and OSB exterior sheathing, air sealed seams, housewrap, 2" polyiso, and drainage plane, and metal siding. I will start with this minimalist insulation (polyiso) and good air seal. Drawing I made below depicts this. Later as budget permits, add netting and blow in cellulose, and finally a plywood interior wall that I will air seal with a paintable sealant such as BASF Masterseal NP-1

That sounds like a good plan. Although when you get to the interior plywood I'm not sure it's worth doing much air-sealing if the layers on the outside have been doing a good job.

I can’t see the big picture but if you are spending the money to building 2x6 walls and a flat ceiling why waste your money on the 6x6 posts?

Build the 2x6 walls and put trusses 24” on center sounds like less money to me.

Walta

Walta, I already have 8 trusses that will be 8ft on center. I also have the 6x6's. While I could sell the 6x6's and recover my money as they cost me very little, I would not be able to switch to 24" O.C. trusses without incurring a significant cost increase. With 8ft spacing of trusses, I would have to very significantly reinforce those load points, so I think the 6x6 might make sense in my situation. Not to mention, I just drilled the post holes last weekend. :) In hindsight I think you are right. I am just trying to figure out how to air seal the barn/shop.

As I see it pole barns are designed to be a low cost way to keep your tractor dry. They are great for that the problem start when you decide you want to heat and cool the pole barn. They are nightmares to air seal and insulate properly.

Most of the time we get the questions after the building is up someone will be asking how do I air seal and insulate for a song as I spent the whole budget on the pole building. At least you are thinking about it before the siding is on.

I am afraid all the choices that make a pole barn cheap to put up make it more expensive to seal and insulate.

I like a bargain as much as anyone, I hope yours is a bargain by the time you get done.

Walta

I see your point Walta. I indeed am hoping to make wise decisions given my facts.

I found a video of a post frame house that used a WRB to seal the roof and walls and meets passive house air sealing standards. (Video link below)

The builder actually wraps and tapes the entire house with no eve or ridge venting at all and insulates at the ceiling level. The blower door test even made Passive House standards.

He is in upstate NY, so I do not know if this would work in my mixed-humid 4a Nashville climate.

If great care is taken, could I not use tyvek on the wall girts, and an economical roof WRB and do the same thing? I can plan in accord with my insulation and the housewrap to make sure seams fall on wood supports.

I made the drawing below to visualize the details.

Thought are most welcome.

Link to video of the passive house post frame house: https://youtu.be/PKXNwdvUNj4

What is the interior wall finish?

Is there a code required fire barrier between the polyiso and the finished space?

I think an overhanging roof is a safer bet than no overhang.

Almost anything can be done but is the juice worth the squeeze?

Walta

Walta, no code for shop. Eventually I will have a plywood interior wall/ceiling with additional insulation.

I have enough metal on hand for the interior ceiling/walls, but I have a few concerns with metal based on comments and the additional reading:

1. when the shop heat is off, the cold surface will be a condensation surface. - My biggest concern with metal.

2. metal will not allow drying to the inside.

3. plywood will be better for mounting shelves, cabinets.

Am I violating any building science principle that will cause me a nightmare? Anything I am doing that will be a nightmare, I will not do. If in my pursuit of free and cheap materials, I don't get the most intelligent approach, I am OK. I am trying to decipher and understand but I need to know the answer to "why?"

So, dad, please help me "understand" if/why I am making a big mistake. :) I am not too far down this this path. I can make some serious readjustments if need be.

I don't know if I mentioned it, but the building will

be 28x56 with 16ft walls, and it will be oriented east/west.

Thank you.

Mike,

You are in pretty mild climate, it might not be worth while to go nuts on insulation, filling the walls might not be needed. I think your plant in comment #4 is a good one. I would just move the plywood to the inside, you get interior finish and bracing for the same cost. You can tape the seams on the foam outside for your air seal.

For the ceiling, easiest is taped OSB, make sure to put strips of OSB above your top plates and extend out to the edge of the foam and tape it there. You can than carry your air barrier from the outside of the foam, across this strip and finally to the interior OSB. You can use a membrane in a similar fashion, but the cost of these is not significantly less than the OSB which can be your finished surface. You can also put the tape on the attic side so it won't be visible.

Thank you Akos. That is very helpful details. I have one concern: Tapng Polyiso. My Polyiso is weathered from sitting outside for some time; however, I just went out and took a pic and it looks like a wipe down of the seam areas with alcohol would make it ready. I might could also use a primer to help with adhesion if you think that would be wise or not if overkill.

-Mike

Cleaning up the surface should be enough. You might want to "butter" the side of the insulation with canned foam as you install them(easiest is with one of those pro spray foam guns).

If you want a pants/suspenders approach, you can also detail your house wrap as a secondary air barrier.