Minisplit Operation

Hello All,

I have read countless entries on this site (thank you all for the guidance) and wanted to gather your thoughts on my current situation.

I have an addition to a house I recently purchased. 3.5 of its walls are exposed to the exterior. It is 19’x13′ with 10′ ceilings and on a concrete slab attached to an entryway. It was discovered that this room had issues cooling in the summer and heating in the winter. I believe there is minimal insulation in the addition. I am located outside Boston and the loadcalc for the room came to be around 17k BTU for heating and 9k BTU for cooling. This was confirmed with loadcalc and coolcalc.

Due to the calcs, I was advised to get a Mitshubishi Hyper Heat MUZ-FS15NAH with a MSZ-FS15 head. It was designed 1:1 to help maximize turndown. It was sized to primarily help with heating in the winter months to offset the high oil prices.

To my situation –

During the end of summer, it started to raise the humidity in the room. This is when the temps were low 70s outside. I realize this is a by-product of an oversized unit. I minimized this issue by disabling the fan when the set point is reached.

Now that it is the heating season, the unit seems to be cycling and does not really modulate down to the ~500W when at its 5.2k BTU rating. The room is set to 65 with an outside temp of 30 at night and the unit will heat for 20+ minutes until it reaches 3 degrees above the set point. It will then stop the compressor unit outside and run the blower fan very slowly, but the unit does not modulate down. It goes from 1.2kW to 0, then waits, then spikes back up.

The original plan with the installer was to have this unit heat/cool the entryway it is attached to (a 120sqft area that is over a dirt crawlspace and two exterior walls), but I cannot seem to get enough supply into this area before the unit senses the temperature increase and kills the compressor.

Is this behavior normal? I do not have a full understanding on how the modulation works. Is it a product of being in a shoulder season? I want to have an efficient system that works properly and saves me money vs the installed hydronic system with an oil furnace. Should I have gone with the FS09NAH unit?

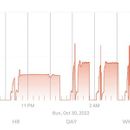

I appreciate any insight or advice on this matter! I have attached a graph for the power output with the unit. Again, the indoor unit was set to 65 and the outside temp was low 30s (there was ice buildup on the bottom of the unit in the morning)

Thank you!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I will see if I can find anything but ice one the heat pump is a big red flag. I would be taking pictures to have when you speak to the installers.

Your heat load is prolly 5k max on that room. So with an 15k you are oversized especially for the shoulder season. Your turndown is about 2.5-3 so the lowest that unit can pump out is 5k btu which as mentioned above is most likely your design day demand… so right now is oversized. So essentially it is too early to modulate in New England for anything but the smallest of systems . The behavior of the unit is normal. The current crop of Mitsubishi and Fujitsu splits don’t really modulate but ramp up to max, then pick compressor speed from 20 to 100 rps depending on the r410 return temp and pressure. Indoor fan speed is selected by the sensed temp delta from the indoor setpoint. So as the setpoint approaches the fan speed my slow down, but unless cold outside there will be no modulation as setpoint is reached before the returning r410 pressure has a chance to drop and compressor rpm’s reduced. Also unless you are running a wall thermostat there will be no modulation as return air temp sensing in the head is just horrible, inaccurate and reached too fast - hence no modulation.

Hope this helps

Hi Mr_reference_hugh - The ice was on the bottom of the base pan at the drain port. It was a frozen drip. Just wanted to clarify as there is no ice on the unit.

Greenright - Thanks for the info. Do you feel the unit it too oversized to be adequate during the winter and will cause issues? I am satisfied is the operation is normal and it is not suspected to be a huge issue. I understand that shoulder seasons are tough, and this October has been pretty warm. The main reason for this purchase was for winter heating. We mainly keep the room at 60-62 degrees and do not start heating regularly until mid-November. The baseboard hydronic heating was not adequate for the room's size, and the boiler would always cycle to supply this room.

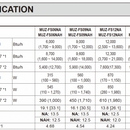

I've attached more technical data on the unit. I am trying to understand why it is not running at the lower wattage. I have a power meter on it, and it runs to its rated capacity, but doesn't seem to modulate down. If it is 43 degrees outside, and the inside temp is set to 70, shouldn't it be going down to 660W @ 5490BTUs? It seems to just be staying at the rated wattage of 1155W @ 16000 BTUs. I'm sure I'm missing something, but I'm trying to understand that. I knew the sensor reading would be off, so it does have a wireless MHK2 thermostat hooked up to it that is in the corner away from airflow.

On another note, this unit was also picked to help supply air to the first floor because a cold entry way is attached to it - which has a dirt crawlspace beneath it. The door between these rooms is normally open, but the air is not really flowing through the door. Are there any tips to help improve this? There is a small attic space above the entry way that could be used to help move air via duct work, etc... If the output air can get to this entry way more balanced, I suspect the load would be very balanced. I attached a floor plan. The red arrows are the mini split. The green arrows are for an in-wall air share unit. The highlighted area are the two ideal locations for it to mainly heat. It was thought to have the baseboard heating take care of the other areas.

Thanks for the help and helping me understand how it operates!

Starting at 1 am it looks like your unit went through 5 long defrost cycles. Those quick peaks in power really give it away. Then ran at max speed for a bit to make up after the defrost cycle. Any way you can post a zoomed into picture of those peaks?

Here is a zoomed in view of what a defrost cycle looks Iike. This was a quick one and they can run for a substantial amount of time with a lot of ice buildup. You can see the drop just before 4:20 and that is the reverse valve moving and then the jump in electricity consumption as the coil is defrosted. It reverses and you can then see it briefly surges the compressor to make up for the defrost cycle. Its then modulates at its pre defrost level.

I'm south of you in CT and this time of year my mini splits will defrost more often due to the climate this time of year.

Edit: I just found a really long defrost cycle from February where it took 10 minutes to defrost and attached that as well.

Hi bfw577 - I attached a photo of the defrost cycle. Thank you for showing yours as a comparison. I am trying to understand how it modulates and if the graph looks correct and the operation is as designed with the fact in mind that during shoulder seasons, it will behave differently than during Jan/Feb.

Is there any possibility that the Mitsubishi control system had been disabled to allow aftermarket thermostat to control the unit.

Ice/ frost on the coils would be normal when the frost limits air flow the unit will do a defrost cycle. Where it is taking heat from the house to melts the frost on the coils. The frost turns to water and will end up under the unit. If you have weeks at a time when it never gets above freezing the drain holes in the bottom of the unit may get blocked with ice and the water can no longer escape the unit you may need a heater for the drain pan but you should avoid this if at all possible as it uses quite a bit of energy that is wasted. Water /ice under the unit is normal and frost /ice on the coils is normal so long as the ice does not stop the fan or limit the air flow.

I like to record the supply, return and air temps of new equipment to help me understand how it should preform and I can tell when it is not.

When I look at the power graph, I do not see any defrost cycles in this sample. I would expect a defrost cycle to happen sometime in the middle of a long run and I would expect defrost to operate the compressor at max while defrosting.

Consider air sealing and insulating this room throwing equipment and energy at a comfort problem is only hiding the problem.

Walta

Hi Walta - Thanks for the reply. I'm not sure about the control board, but the MHK2 is a Honeywell thermostat designed to work with the Mitsubishi mini split via RedLink.

I believe that there are defrost cycles occuring. The indoor unit will shut down and close its baffles. The indoor blower will run on high. The outdoor unit will reverse flow. After a couple minutes, the baffles reopen and the unit resumes heating. What else do you think these spikes could be?

In your experience, what numbers are you looking for and how do you use them? Can you please provide an example? Thank you!

I have not looked at the red link system but every other third-party thermostat I have looked at killed the variable speed and commanded the heat pump on or off or maybe hi low and off.

My Rheem HP averages over 6 hours of run time between defrosts cycles but that is very weather dependent.

The most common failure with heat pumps is a refrigerant leak/ low charge. It starts as poor performance, reduced efficiency and excessive defrosts cycles slowly progresses toward zero heat over time as more leaks out. Making an accurate diagnosis is difficult / impossible when the losses are small. If you can show the tech the unit use to blow 95° air with 68° return air when it was 30° outdoors and it does not any more they are much more likely to look harder for a problem.

Walta

Hi Again,

The same operation is still occuring. I am trying to understand why this is happening and gather with certainty that this is not correctly operating. Outdoor wet bulb temp was around 35 last night. Heat was set for 70 on auto. Attached is the power grid. Indoor unit outputs heat at around 115F-120F.

Again, it seems to ramp up, run at rated capacity, and turn off because of overtemp. During all this operation, the outdoor fan never stops running. I'm not sure on the RPMs but it is turning very quickly and doesn't seem to ever increase or decrease. It stays the same speed. I know we spoke about oversized equipment, but the unit turns on within about 2-4 minutes after turning off, so there should be an adequate load if it can modulate down and stay there.

Can someone please help me understand what is happening here and what I'm looking at?

Thanks!

I don't have any solution to your problem, but I experienced something very similar with an oversized Mitsubishi minisplit once. I didn't have a power monitor on it, but it would overshoot setpoints by 2-3 degrees then shut down until it was time to turn back on again. A temperature graph looked more like what you would expect from a single stage unit than what you'd expect from a modulating unit.

I'd bought it from one of the large online retailers and sometimes wondered if I'd received a fake. Where did you buy yours? And did you have it installed by a reputable company?

If you want to use the variable speed ability of your Mitsubishi heat pump you need to use the factory control system.

When a after market thermostat is connected to the heat pump it only has the ability to turn the heat pump on or off exactly as your power graph shows.

I recall others complaining that the Mitsubishi Kumo Cloud system does not have the ability to modulate the compressors speed.

Walta

Thanks Walta, but I was reassured by Mitsubishi tech support that the MHK2 allows for full modulation. Regardless, I just ran it without the MHK2, and used the unit's sensor.

It is 30F wet bulb, with the thermostat set to 70. The room went from 60 - 70 in about 2 hours. It then hit 72 and turned off the outdoor compressor. I still do not think this is operating correctly. The tech first said this behavior is normal on the MSZ-FH15NA, but it doesn't make sense with the technical engineering data I found. The compressor outside seems to be running at 50% capacity and outputting ~12k BTUs. This explains why the room goes over.

Shouldn't it ramp down to around 600-700 watts when the temp is hit? It just runs, shuts off, then restarts 2 minutes later.

Thoughts? Thanks.

Can you dig up the installer options for your unit (not the easiest to find) and post what they are set to.

It could be some setting is off causing your issues.

I will try to find them for the units and controller.

The current crop Mitsubishi and Fujitsu modulate based off two things- the difference between setpoint and room temp and the high/ low pressure sensor readings. Thus if you use a 3rd party thermostat you will get only partial modulation based on pressures.

Hi Greenright. Thank you for both of your replies and information. That makes sense. The unit is seeing 83 intake air with a very high delta t (see below) - I'm thinking this was way oversized by the installer and could be a result of not enough return air to lower the temp over the head unit?

I think I found part of the issue. The intake temp is around 83 and the output temp is about 122. I understand that to be a very high delta t - which seems to suggest an issue. This was measured at the intake vent and output vents with the unit on high. I'll be reporting this back to the installers, but sounds like an issue is obviously happening here.