Novel idea for low cost exposed rafter unvented cathedral roof insulation – good or bad idea?

Hi, I’m owner building a gable end pavilion house in Orange NSW Australia.

Our climate is something like 3b in the US I think: 27″ of rain, snows once or twice a year but very rare to get 2″, winter lows of 31F, highs of 50F and in summer lows of 57F and highs of 81F.

Mostly we worry about heating here, not cooling but that could be because our houses are pretty leaky. We also don’t have all the materials & systems available here that you have in the States eg. ZIP sheathing.

I’ve been watching Joe Lstiburek & Matt Risinger and trying to get my head around perfect walls, building science and high performance building.

I’ve come up with a scheme to build a low cost “monopoly” type house but there are a couple of novel details that I’d like to get validated by the community here.

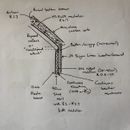

We want to have exposed rafters in parts of the build and so to have enough insulation I thought to combine rigid and bulk (glass wool) insulation above the OSB sheathing and WRB. So the layers from inside out would be:

– Rafters

– Shiplap boards (or OSB where there are flat ceilings and conditioned attics)

– Vapour permeable WRB

– 1″ to 2″ rigid XPS

– 4″ to 8″ of glass wool bulk insulation

– Small air gap via tall roofing battens

– Anticon roofing blanket (it’s a combo silver sarking and glass wool blanket commonly used in Aus to stop condensation under corrogated metal sheet roofing)

– corrugated metal sheet roofing (zincalume custom orb)

In Australia XPS is much more expensive than glass wool insulation which is why I’m trying to use both above the exposed rafters and shiplap lining.

Attached is a diagram of the arrangement, you’ll have to excuse the metric units, if it helps 25mm = 1″, 90mm = 4″, and you have to multiply our R values by 5.7 to get yours 🙂

Is this a very good or a very bad idea? Thanks!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

You generally want your WRB on the exterior side of your assembly, so that it can protect everything behind it. It doesn't usually hurt to have a secondary barrier further in, but that's not usually necassary. In your case, the XPS is already nearly a vapor barrier, so there isn't a lot of point in having a WRB right over it in this assembly, since the XPS won't care if it gets wet, and it doesn't allow moisture migration, so the "vapor permeable" nature of your WRB doesn't accomplish anything. I would move the WRB further out, and just tape the seams between sheets of XPS.

I'm not familar with that "anticon blanket". I'd probably want that to be vapor permeable, which it may well be.

I think your assembly is probably OK aside from the points I mentioned earlier. Since you have a vented assembly and no mositure traps, you should be safe from a moisture standpoint as long as you make sure to keep any bulk water out of the fiberglass insulation. You may want to try to find polyiso (polyisocyanurate) rigid foam insulation, which is commonly used on commercial buildings and flat roofs here, so it might be available in your region as well, and may be cheaper than XPS since you mentioned XPS is extremely expensive for you.

Bill

Is OSB or plywood unavailable or very expensive? It seems like nobody in Australia uses OSB or plywood roof sheathing, but instead puts anticon blankets under the roofing material.

Thanks Bill, that makes sense re the WRB, I was wondering if something like Tyvek Drainwrap might be suitable in that layer to take any water that might get through the XPS away?

XPS isn't "very" expensive here, just more expensive than glasswool. Polyiso is more expensive again, while foil faced EPS is about the same price as XPS.

To give you some idea of prices - 1" R5 XPS is about $1USD / sq. ft while 6" R20 glasswool is about the same, so to get a reasonable R value in XPS would cost me 4x the glasswool. 1" polyiso is more like $2.50 / sq. ft.

Hi Stephen, OSB and plywood are available here, OSB only more recently, but you're right sheathing, especially in the roof is very uncommon. 1/2" OSB (2x 1/4" because that's what we have) costs about $2USD / sq. ft while 1/2" plywood is $3 / sq. ft.

Not sure how that all compares to what you guys pay or if I'm just trying to do this on the cheap :)