Rainscreen details at foundation

Hi all,

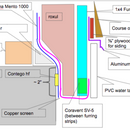

I am looking for advice/comments on my current rain screen and exterior insulation details on a renovation. I have an inch protrusion of my foundation from the sheathing.

Thanks in advance,

Bridgette

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Bridgette,

It's probably OK, but you are asking your ProClima Mento 1000 (which is basically housewrap) to do a lot.

This housewrap isn't flashing. If it gets a hole in it, water lands on your slab.

If this were my house, I'd use copper flashing or peel-and-stick flashing at the bottom of the wall, where the WRB leads, to conduct any water beyond your triangular foam filler piece.

I agree with Martin. Peel & Stick will give you an air and water seal, and will likely be more rugged than the Mento, though that looks like pretty rugged stuff. On that note, the Mento is designed for roof surfaces, and to take walking and abrasion, as well as sealing around fasteners on nearly flat roofs. it seems like a bit of overkill for use on vertical walls, especially behind layers of Roxul and a big drainage cavity. Are you using the Mento for all of the building paper, or just as a base flashing?

Also, the aluminum drip cap is probably unnecessary. The PVC water table doesn't need it, and your drainage gap runs behind the PVC, so water would naturally run out the bottom anyhow. Leave out the plywood starter strip and just let the first course of siding lay on the PVC trim. The slight extra kickout on the siding looks better anyhow and the siding acts as the flashing for the trim.

Hi Martin and Peter,

Thanks for your thoughtful answers. Yes, Peter we chose to use the Mento for all of the building paper since our sheathing is mostly 1" gapped 3/4" thick 1x12' rough cut diagonal oak boards with plywood patched in where there was rot.

I originally planned to use stainless flashing or peel and stick but our foundation on the majority of the house where a lip exists is stone and irregular. The peel and stick manufacturers said their product needs a flat surface. Therefore we plan to use a lot of Contego HF caulk to fill the dips to allow the mento to seal.

Could I install a 3" strip of flashing (aluminum maybe?) over the wedge attached to the sill but under the mento just in case any holes develop and still make the lowest seal to the foundation, mento and contego HF?

Bridgette,

If peel-and-stick flashing overhangs your foundation by 1 inch, it doesn't really matter if it sticks to the irregular stone. As long as it directs water to the exterior, it will still work.

Aluminum flashing isn't as durable as copper or stainless steel, but you've got the right idea -- some type of redundant system under the Mento would be helpful. Caulk isn't flashing, even if you install gobs and gobs of it.

Thanks Martin. just to clarify for my contractor....the gobs and gobs of caulk are for air sealing, the copper screen for insects and the metal stock for flashing.

Peter, re the aluminum drip cap, our PVC is 1" thick. Would that still look ok? Any pics of this in vivo?

Bridgette,

I'm not sure the Cor-a-vent between the furring strips does much. If you are content to protect the bottom of the Roxul with copper mesh, why not do the same with the bottom of the rain-screen cavity? There also doesn't appear to be anything to attach the Cor-a-Vent to anyway.

Sorry, but no photos handy. The best way to see whether it looks good is to do a small mockup on your walls when you get started. This is not a big deal either way, but it can save a few cents.

I am now trying to decide if I want to do away with the foam filler and use the aluminum stock to put an angle on the lip while providing the 'backup' water barrier if the mento fails? Thoughts? See pic.....

Bridgette,

Whether or not this will work depends on the gauge of the aluminum you specify. Thin aluminum is quite fragile. You want a heavy enough gauge of aluminum to hold crisp angles and not distort when it is installed.

Bridgette,

As Martin said, as long as you use a thick enough gauge stock (which you would want for longevity anyway) it will work fine. Remember the angle of the pitch to shed water only needs to be 6 degrees, so the full width of the Roxul can extend almost down to the foundation.

It looks like you have decided to go with Peter's suggestion and lap your siding over the water table. if so you can also eliminate the 3/4" starter strip.

Correct me if I'm wrong, but wouldn't this mock-up be a whole lot easier if the sheathing was co-planer with (to?) the slab edge?

Malcolm,

Any guesses on what is considered thick enough? For costs we plan to go with aluminum. Thanks for the clarification on the 6 degree slope. My contractor can probably bend that on a metal brake, ya think?

John, Two side of the house were built this way. We decided to deal with it at the bottom so we didnt have to bring the facade out the from the top to bottom.

Bridgette,

I've never used Aluminum flashing but looking at some of my old standard specifications, it seems a thicker gauge may be necessary than when using coated steel, where 26 gauge would be fine.

Perhaps a poster with some experience using aluminum can chime in.

BTW; Good luck with your reno!

And yes it should be easy to bend up on a break.

Bridgette,

For sheet metal (steel) ducts or stovepipe, 30 gauge is the thin stuff, and 26 gauge or 24 gauge is the thick stuff. Like Malcolm, I'm not sure when it comes to aluminum.

Bridgette, aluminum "trim coil" is readily available at any supplier of siding or roofing materials. It's usually available in two thicknesses; the thicker type is a nominal 0.021" or 0.022". Any sheet metal brake should be able to bend it. Just don't put the aluminum in contact with the concrete, as galvanic action (aka electrolysis) can corrode the aluminum.

Having used Mento and aluminum quite a bit, for your application I would consider using a heavy-duty membrane flashing instead, to avoid galvanic reaction and to reduce thermal bridging. Pro Clima Extoseal is a zero-VOC material made for this application, and there are many other options, such as Grace Vycor.

(This is a house I helped build, where we used Extoseal in a comparable application: https://www.youtube.com/watch?v=_RdwXUQU_E4.)

I am leaning towards galvanized steel. Would this interact with the concrete?

AMERIMAX HOME PRODUCTS 70004 4-Inch x 50-Feet Galvanized Flashing https://www.amazon.com/dp/B000BPBZGC/ref=cm_sw_r_cp_apa_8JqzBb39E43D4

Scored cheap stainless steel flashing. Can anyone confirm the fasteners to use for the flashing and for the copper screen. My guess is stainless roofing nails for both but wondering if stainless staple gun staples will be enough for the copper screen on the sill plate?

Thanks!

Bridgette,

Staples should be fine. The fasteners for the water-table are going to hit the screen anyway. The staples are really just to hold it in place as you build. It can't go anywhere once the assembly is complete.

Bridgette, that's great. Stainless fasteners are the best choice for the stainless flashing. They will corrode the copper screen over time, but like Malcolm said, it shouldn't be a problem for your situation. If you're concerned about it you can use copper nails or staples for the screen.

Thank you! Can't wait to get started!