Rockwool Lambda values vs density – compress, and how much to increase R/cm?

Hi all,

I’m building a tiny house from only second hand building materials. This is an amazing challenge that has been keeping me busy for the past couple months.

I’m now starting with the insulation, for this, I’ve chosen rockwool, as it is readily available on the second hand market, and thus the most sustainable option, in my opinion.

Till today, I only bought 100mm rockwool with a thermal conductivity of 0.035W/mK, as that provides a 5 to 10% insulating improvement over the cheaper 0.037 and 0.039 rockwool.

However, very long story short, I got my hands on a large, super cheap batch of 140mm, 0.037 rockwool. My understanding is that 035 is denser (35kg/m³?), aka more compressed during the manufacturing process.

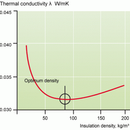

However, rockwool intended for flat roofing is even denser (60kg/m³?), but has a lambda of 0.040. So there must be a sweet spot, or maximum possible insulating capacity somewhere in between, my guess would be that that is 0.035 for rockwool. The attached chart seems to confirm this partly, it is however not specifically about rockwool .

My question thus is, how much would I have to compress my 0.037 rockwool in order to get close to 0.035?

I guess I could use the densities for my calculations, but I can’t find the specific densities of 035 and 037 rockwool.

Looking forward to your views.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I've been roaming the internet for the past hour, this is what I came up with:

Rockwool 33kg/m³ 0.037

Thermalrock s40 0.036

Rockwool 45kg/m³ 0.035

Thermalrock s50 0.034

Thermalrock s80 0.034

Roofrock 120kg/m³ 0.037

Thermalrock s80 0.034 (why??)

Hardrock 160kg/m³ 0.039

Hardrock 180kg/m³ 0.040

So the curve seems pretty darn flat at the bottom, that would indicate that the "never compress rockwool" is clearly a myth, it seems to be very difficult to compress rockwool too much / so far that it degrades performance.

Now I will assume that density is the determining factor in thermal conductivity.

The difference in density between RW 037 and 035 is 30.7%

The difference in thickness between my cavity (100mm) and my lambda 0.037 insulation (140mm) is 33%.

Compressing the whole 037 bat down should thus result in insulation with the same performance as my RW 035 insulation.

Now the next question arises: I read that during the manufacturing process, the wool is compressed with a curing agent, which is then heated so the wool maintains its shape. Is there a way to compress the rockwool more permanently? To prevent it from pushing too much on my thin (9mm) exterior sheathing.

Where are you finding rock wool available on the secondary market?

Mostly marktplaats, the Dutch Craigslist.