Top-Vented Metal Roof Assembly

Hi everyone,

I’m in the planning process for a home I’ll be building in Quebec (Climate zone 7A. Wall assembly is pretty much sets (drywall as AB, VB, 2×6 with batt insulation, plywood, WRB, vapour permeable panel insulation, rain screen, cedar shingles), but I’m still debating over the roof assembly.

The roof is 12 12 pitch cathedral ceiling, framed with 2×12 and covered with corrugated metal roof. I want to avoid foam as much as possible for environmental reasons and because I already had an ants problem in the roof foam (XPS) of a chalet (they really love that stuff). I’m aiming for anything above R49, continuity would of course be a huge plus.

After reviewing pretty much every options there is, it seems that batt insulation between the the rafters with panel insulation on top would be my best bet (I ruled out dense packed insulation because I want to make most of the work myself).

Could anyone point to me a cold roof assembly that would work?

Until now, I have, from the interior :

-Drywall as AB

-VB (probably membrain)

-2×12 with batt insulation (Mineral wool or Hemp wool)

-Plywood as secondary AB

-wood fiber panels

-1 by 4 or 2 by 4 grid layed flat (vertical and horizontal) for air circulation under the metal roofing

-metal roofing with ridge vent

My questions are :

-Where should I put the WRB?

-Could I use waxed wood fiber panels with appropriate taping as my WRB like they do in most European wood fiber panel assembly?

-Is it possible to make this assembly a cold roof assembly? If so, how do I vent below the deck if the plywood layer is below the wood fiber panels? Can I just remove the ply from the assembly and have the grid under the metal roof as my venting?

-If this assembly can’t be made into a cold roof assembly, would moving the panel insulation on the inside and add vent baffles above the batt insulation achieve that in a smart way?

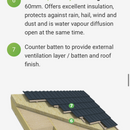

I attached a diagram of (approximately) what I had in mind (from the Steico website)

Thanks in advance!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

If you follow the ratios of a hybrid roof assembly here:

https://www.buildingscience.com/documents/building-science-insights-newsletters/bsi-100-hybrid-assemblies

You are going to need an awful lot of exterior insulation if you fill the 2x12s with fluffy.

Top vented roof is not quite the same as a standard vented roof, you do get some drying but it still can't be treated as a fully vented assembly as roof deck will limit moisture transfer.

For metal roofs, typically the underlayment goes directly under the metal panels. You can also put it above the vertically strapping but bellow the horizontal ones.

Make sure to detail the OSB/CDX roof deck bellow as the main air barrier. This is the most important detail to get right if you want a durable roof.

If you don't want to run the full ratio (60% exterior rigid), I would set up your roof here:

https://www.ubakus.com/en/r-value-calculator/

For outside design temperature, you use the average outdoor temperature during the 3 coldest months.

I would guess that a top vented assembly with fiberboard over CDX and with a warm side vapor retarder, full insulated 2x12s with batts and maybe 30% exterior fiberboard insulation might get you by.

Insulating from the inside might be simpler in your case though. You can definitely move the panel insulation to the inside as well but you need to make the 2x12 space vented. You can use smaller batts say for 2x10 studs and baffles in the rafters. In that case the metal roof can go right over an underlayment directly on the OSB/CDX deck.

Hi Akos,

Thanks for your reply and references! I think I had trouble understanding the difference between vented, top vented and non vented assembly when using vapour perm insulation. Do you know if there's any articles about top vented assembly with vapour perm insulation on GBA? I couldn't find any.

In any case, I'll make sure to run the numbers in ubakus. Based on the material available in Quebec, I'll probably do from the inside :

-Drywall

-VB (poly or membrain depending on budget)

-2x12 rafters with 9,5" of hemp wool close to the sheeting (R35)

-Plywood sheeting with taped joint and continuous with the wall plywood sheeting as AB (monopolie framed, so easier to get it airtight)

-2 layers of gutex multiterm 80 joints stagered (R22,8)

-Vapour permeable WRB over the Gutex as recommended by the manufacturer (probably Solitex Menthos 3000)

-3x3 Vertical strapping going over the walls to be used as roof eaves (dimensions tb confirmed with my enginer)

-2x2 Horizontal strapping used as roof rake (dimensions tb confirmed with my enginer)

-Metal roof

Do you think that this assembly makes sense? Do I loose too much of vapour poremeance by locating the WRB directly on the deck instead of above or in the middle of the strapping? That's mainly for esthetic reasons.

I'm I correct in thinking that the airthightness of the VB is less critical if I detail well the plywood as my main AB?

Thanks again so much!