Roof insulation plan – low slope

I have a new question about our roof — I have edited my original question…

Climate zone 5

Low slope, unvented roof assembly

We are following what is recommended in Martin’s article “Insulating Low-Slope Residential Roofs” https://www.greenbuildingadvisor.com/article/insulating-low-slope-residential-roofs

—“You can install a more moderate thickness of closed-cell spray polyurethane foam on the underside of the roof sheathing, supplemented by a layer of air-permeable insulation below that.”

We need a minimum R-value of 41% foam for our climate zone. Our insulation contractor likes BIBS for the air-permeable insultation. With an available space for insulation of 11-7/8” (I-joist), I calculate minimum of 3.6” of closed-cell spray polyurethane foam (R6.5/in) with the balance (8.275”) of BIBS (about R4.1/inch). That would be a total of R57.3 – except for thermal bridging…

Sounds like thermal bridging is not addressed with this assembly. How bad is thermal bridging with 11-7/8” I-joists? Can you put a layer rigid foam between the I-joists and the roof deck to mitigate thermal bridging? I imagine that the rigid insulation would need to be bonded to the plywood to eliminate any air.

Thanks again,

Alan

Original question—–

We are building a home in the northwest suburbs of Detroit in climate zone 5a. Ground snow load of 25 or 30 lb/ft2. It is a ranch home with a gable roof – basically no valleys or dormers. The ridge beam runs east-west. It’s a pretty flat roof – the north side is 1-1/2:12 and the south is 2.4:12.

Most of the roof is I-joists – 11-7/8” @16” OC with a cathedral ceiling. Some areas will be trussed on the north side with a flat 9′ ceiling.

Planning a standing seam metal roof – probably a darker color like dark bronze or something a few shades lighter.

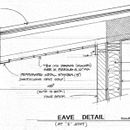

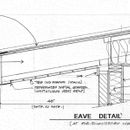

I have attached the current details (for both the I-joist and truss areas). For the wall assembly, we have already made plans to add rigid insulation outside the sheathing to a minimum of R7.5 with a 1” airspace between the insulation and the brick– this change is not reflected in this detail. I have questions about that, too – I’ll ask in a later post.

The layers are noted on the details.

Is this a good plan?

The eaves are 4’ from the studs in most places – would you insulate the eaves on the south and west sides to avoid ice dams from cladding thermal plumes?

Should our strategy be to ventilate as it’s planned? If so, would we need a ridge vent or vapor diffusion port?

Alternatively, should this be a conditioned space?

Thanks in advance, Alan

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Alan,

I haven't had en0ugh recent cold-climate experience to c0mment on the ice-damming implications of insulating the eaves, but did notice you don't have an air-barrier separating the batt (or fibre?) insulation from the air moving through the soffits to the vent channels. It's a good idea to include one to stop the wind-washing which will reduce the effectiveness of the insulation.

I'm not comfortable with low-sloped roofs detailed the way you have for several reasons. Although some metal roofing suppliers allow their products to be used on what are essentially flat roofs, I think it designs unnecessary risk into the assembly. I also don't think there is sufficient difference between the eaves and peak to generate the air-movement necessary for effective ventilation. However in discussions about similar situations here on GBA other have offered differing opinions on this, so I'll leave it to you to decide if you share my misgivings.

I appreciate the input. Sounds like I need to be more open minded about a single membrane roof. Thank you, Alan

Alan,

A couple of issues:

1. A slope of 1.5 in 12 makes this a low-slope roof -- in which case you can't use conventional venting details. (There isn't enough difference in elevation between the soffit vent and the ridge vent in this type of roof to encourage air flow.) For more information, see "Insulating Low-Slope Residential Roofs."

2. You wrote, "We have already made plans to add rigid insulation outside the sheathing to a minimum of R-7.5." But installing rigid foam on the exterior side of your ventilation channel is a waste of insulation. The ventilation channel introduces exterior air into your roof assembly. [Later edit: I see that you have edited your original question to make it clear that the exterior rigid foam will be installed on the wall, not the roof.]

Responding to Martin’s post

I edited the paragraph starting with “I have attached the current details...” to note that the wall plan was changed to add exterior rigid insulation, not the roof. The roof assembly plan is what’s in the attachments.

Based on what both you and Malcolm wrote, regarding the low slope of the roof, can I assume you would not ventilate it?

From reading elsewhere on GBA, it sounds like I-joists don’t act as much as a thermal bridge as my 2x6 studs would. How does this impact the need for external insulation (on the roof)? What do you suggest to use as insulation material?

Also, esthetically, we prefer the metal roof. Are we better off choosing a dark one as noted or lighter? Or does it matter? (Regarding phenomena light night sky radiation.)

What single membrane alternative is better? How thick and how light or dark would we choose?

Sorry for the misleading question, I hope I adequately corrected it. Thank you both for the prompt replies.

Alan

Alan,

Q. "Regarding the low slope of the roof, can I assume you would not ventilate it?"

A. I urge you once again to read my article, "Insulating Low-Slope Residential Roofs."

A low-slope roof can be either vented or unvented. But if it is vented, it needs special details -- a very generously sized air gap between the top of the insulation and the underside of the roof sheathing, and several "doghouses" (vented cupolas).

The R7.5 is on his WALL sheathing, not the roof. (I did a double-take on that too.)

Alan,

Part of my roof and wall is similar to yours (Toronto, Zone 5). Roof 1.8 to 12 slope built with 2x8 , insulated with closed cell spray foam (R30) and batts (R7). Unvented roof with standing seam panels (black).

The wall insulation runs up all the way to the roof sheathing but the rain screen is stopped at the soffit and vented bellow the soffit. No issues with ice dams at the overhangs (shorter then yours, 1.5') on the south facing walls. Overhangs are un-insulated.

Akos - Thanks for your reply. Is this a large area of metal roof (you mention it is part of your roof)? Does snow slid off your low slope? Is the dark color contributing to higher cooling costs in the summer?

I wonder if the closed cell spray foam of R30 (5"?) "is thick enough to keep the roof sheathing (or the lower surface of the foam insulation) above the dew point during the winter" (as stated in https://www.greenbuildingadvisor.com/article/insulating-low-slope-residential-roofs - Martin's article "Insulating Low-Slope Residential Roofs." - (I read it - again - more closely this time - as he suggested).

I think this will be our strategy for insulating the roof assembly.

Thanks again, Alan

Alan,

Q. "I wonder if the closed cell spray foam of R30 (5"?) 'is thick enough to keep the roof sheathing (or the lower surface of the foam insulation) above the dew point during the winter' (as stated in https://www.greenbuildingadvisor.com/article/insulating-low-slope-residential-roofs - Martin's article 'Insulating Low-Slope Residential Roofs'?"

A. The answer can be found in the article -- look at the table (chart) that shows that a roof assembly in Zone 5 needs at least 41% of the total R-value of the roof assembly to come from the foam insulation layer.

One option that will work is R-20 foam plus R-29 fluffy insulation (for a total of R-49).

If you have R-30 of foam, your assembly is even safer -- or you can add more fluffy insulation if you want. Even R-40 of fluffy insulation would be safe if you have R-30 of foam insulation.

Alan,

The roof section is about 11'x45'.

For the first year I did not have any snow retention, when the snow slid from the roof it sounded like a multi car collision. There is now snow retention.

No issues with cooling in the summer, my office is in a loft area just bellow the roof with low ceilings, the ceiling never felt hot.

One of the commenters mentioned about noise. Any cathedral ceiling is loud compared to an attic, if I could do it again, I would put the ceiling above the bedroom on resilient channels. The problem isn't rain, I quite enjoy that, but critters parkouring above my head in the night. Squirrel feet are surprising loud.

P.S. The only reason I went with this type of roof insulation is because of height limits (ceiling height on the inside and house height on the outside). It was fairly expensive, the other sections of the roof which are a combination of exterior rigid/batt and interior rigid/batt where significantly cheaper to install and perform better.

Alan,

Be sure to specify a high temperature capable roofing underlayment, preferably a self sticking one to help with sealing the screw penetrations. Verify that the manufacturer will back the product for your very low slope. Also verify that the detailing of whatever metal roof you choose will also be certified for the low slope. I will assume that you have had engineering done for the given snow load on the four foot overhangs.

As for ice dams, I have not experienced any on our standing seam roof areas, but I do have R-26 above all the roof sheathing. That said, metal roofs will channel melt water. With a 3 1/2 in 12 pitch this mostly seems to create sliding caterpillars of ice bottomed snow bars that slide down the roof into upside down wave curls. Sometimes as long as two feet. We have no gutters so no problem, just a little disturbing when they finally fall off.

Given the very low slopes you have I would be concerned that gravity alone will not pull the ice off the roof resulting in a pretty high likelyhood of damming sufficient to have water pool above your seam tops. My own house, in addition to higher pitched metal roof, has three roof planes that are as low as yours. I could not get a trustworthy answer to detailing against possible ice dams and ultimately went with a membrane roof material for those areas. My wife can't see the membrane from the ground view, which also affected the choice.

Google "cool metal roofing" or go to McElroy Metal dot com and check out potential sun load. The colors you mention are among the hottest to live with. Even in your area the affect on air conditioning needs could be pronounced. Be aware that finishes on metal roofing vary. The Kynar finishes seem to do well in the sun relative to others, but they still die out here in the southwest. It just takes longer. The installer must be careful not to scratch the finish in any case, otherwise rust will set in and touch ups are just touch ups.

Last but not least, have you been through a storm in a metal roofed house? We fortunately only get small hail here and our total rain fall is less than 5-6" (snow makes up another 6") Even with R-58 plus between the metal and our ears, the sound levels bother some family members. The membrane roof over the bedroom is much quieter. If you do go with a membrane, look into EPDM, TPO and PVC. All have merits and deficiencies. I don't want to say much more than I went with PVC after googling "roof material type" failure. Sales people are sales people.

Roger - thank you for your reply.

re metal roof - we have 2 local reputable installers who recommended the same plan for the low slope. I also spoke with the materials supplier who is very experienced - his recommendations matched the installers' plans. (2" rib, mechanically seamed with a sealant). I didn't talk much about color/heat issues and noise - I will do that. Do you think Mineral wool in the assembly will help mitigate the noise?

We were looking at Sika Sarnafil PVC roofing with ribs that mimic the metal roof, but we didn't like the colors. I should probably revisit that as an alternative.

Thanks,

Alan

Can someone define "low slope roof"? Is a 2/12 pitch considered low slope?

Joe,

Q. "Is a 2/12 pitch considered low slope?"

A. Yes. According to ASTM standard E 1918-97, a low-slope roof is a roof in which the uppermost part is installed at a slope of 2/12 or 1:6 (9.5 degrees) or less.

That said, other sources report that roof assemblies with a pitch (slope) of less than 3:12 are considered low-slope roofs.

Joe,

The answer is a bit contextual. From a roofing perspective low-slope roofs have typically been considered those under 3/12 where either shingles or metal roofing usually require different installation and detailing to remain viable.

From the perspective of ventilation, much depends on whether it is a cathedral roof, or one with an attic space - those with antics being more forgiving. Again I would define them as being any under 3/12.

There are lots of ways to detail successful low-sloped roofs, but remember that even when built diligently, they will never be as robust as their higher-pitched equivalents. To me the most risky are those that don't use the detailing and techniques developed specifically for flat roofs, but rather try and extend the typical pitched roof construction to the lower limits allowed by roofing manufacturers. For example, some snap-lock metal roof can be installed down to 1.5/12. That roof is a lot riskier than the same one on a 6/12 pitch.

I suppose you have to factor in , like always, climate zone and orientation right?

Yes and even the site itself. A low-slope roof which may accumulate debris from overhanging trees may make the flashing details problematic, as may high winds or other factors.

I hate to be repetitive but....

We are following what is recommended in Martin’s article “Insulating Low-Slope Residential Roofs” https://www.greenbuildingadvisor.com/article/insulating-low-slope-residential-roofs

—“You can install a more moderate thickness of closed-cell spray polyurethane foam on the underside of the roof sheathing, supplemented by a layer of air-permeable insulation below that.” Thermal bridging isn't addressed with this type of assembly...

How bad is thermal bridging with 11-7/8” I-joists?

Can you put a layer rigid foam between the I-joists and the roof deck to mitigate thermal bridging? I imagine that the rigid insulation would need to be bonded to the plywood to eliminate any air.

Thanks, Alan

Alan,

It sounds like you are using the flash-and-batt approach. (For more on this method, see "Flash-and-Batt Insulation.")

Q. "How bad is thermal bridging with 11-7/8 inch I-joists?"

A. Because the OSB webs are thin, thermal bridging through I-joists is less significant than thermal bridging through 2x12s or similar solid-lumber rafters. I wouldn't worry about it.

Q., "Can you put a layer rigid foam between the I-joists and the roof deck to mitigate thermal bridging?"

A. No, because the rigid foam is too squishy, and would deform under snow loads. The rigid foam would interfere with the structural connection between the rafters and the sheathing.

We are seriously considering flash and batt or really flash and fill (blown fiberglass). It’s been a decision of asthetics (thick roof) versus the potential health/smell concerns of the spray foam.

If accept a thicker roof and choose exterior polyiso, what R-value should we use to calculate the thickness for the north part of climate zone 5? 4.5 per inch?

Thank you.

Alan,

We can calculate the thermal briding of I joists (3/8 web) VS 2x12. Assumption here is a 15% framing factor for 2x12. Since the I joist webs are thinner, the framing factor reduces by a factor of 4 (1.5" / 3/8"), so 3.75%

OSB has is R1/inch vs most soft wood around 1.25. I jost R value is around R12 and the 2x12 is R13.5.

Assuming R49 center of cavity, whole assembly R value:

Wood Stud:

U value=(1/13.5)* 15% + (1/49)*85%= 0.0285 or R=35

I joist:

U value=(1/12)*3.75%+(1/49)*96.25%=0.0228 or R=44

I joists do significantly better, just make sure there are no air gaps around the webs.

These calculations are very helpful.

Thank you.