Roof ventilation channel outboard of decking: NBC compliant?

Context:

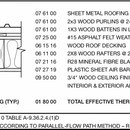

I’m building a small three-season cottage in southeastern Manitoba (Climate Zone 7A). It is anticipated to get limited if any wintertime use. I’ve attached an image of the vaulted roof assembly, which includes a ventilation space outboard of a high-perm roof deck and underlayment (3/4″ pine lumber and #15 asphalt felt, respectively).

This building will be mechanically cooled. For the plastic sheet air barrier at the interior, I intend to use Intello, but may need to substitute a cheaper option such as Certainteed MemBrain. My intuition says that the 6-mil polyethylene which is standard here would be risky with a primarily inward vapour drive during its occupied season, but I’d be curious to hear some other thoughts on that.

I am experienced executing airtight enclosures; moisture load from air egress should be typical of a house with ~1ACH50 overall airtightness.

I have a few questions:

1) Is this a durable assembly?

2) If it is a durable assembly, is the outboard vent space code compliant (see below)?

The applicable code (NBC 2010 9.19.1.1.(1)) says:

“Except where it can be shown to be unnecessary, where insulation is installed between a ceiling and the underside of the roof sheathing, a space shall be provided between the insulation and the sheathing, and vents shall be installed to permit the transfer of moisture from the space to the exterior.” (emphasis added)

Supposing that this is indeed a durable assembly, how can I show the vent space to be unnecessary, for code purposes?

Thanks for your feedback.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Note: This assembly is slightly shy of minimum thermal performance as mandated by code, which is offset by slightly higher-than required performance in other assemblies. Thermal performance is not a priority for this seasonal-use building.

Benjamin,

There are a few phrases in the building code like "Except where it can be shown no to be necessary", and "Unless it creates hazard", which leave the discretion for approval to the local authority. It's up to them to decide what is required for approval. It might be as simple as "That looks fine", they may require modelling , or an engineer's stamp. It's up to them.

The roof looks like it would be fine for a seasonal cottage. Keeping pests out at the eaves and peak may be a bit more difficult as any insect screen will have to conform to the profile of the metal panels.

Thanks Malcolm – These plans will be engineer-stamped, but I'm working with a new engineer, so we shall see...

The ribs will be plugged at the eaves with self-adhered foam closures as is typical around here (not my favourite detail but OK when the fasteners hold it in place). The eave openings between the wood battens will be closed off with perforated metal or a fibrous closure. The ridge will get a fibrous closure as well.

Benjamin,

I tried to get the local building folks to approve a similar top vented assembly. My inspector was fine with it but the planner wouldn't go for it. In the end ended up with SPF bellow the deck.

If you can get your engineer to add in some verbiage to state that the top venting is sufficient for the vent channel above the insulation to be unnecessary, the planner should have no objection.

You will need a decent warm side air barrier, since I assume you don't want to tape the seams of the 3/4 ceiling boards. Detailing Membrane or 6mil poly as an air barrier is possible if you take some care, not something I would outsource though.

Might be simpler to nail up 3/8" OSB tape the seams for a DIY smart vapour barrier. Check with your permitting folks as they might insist on 6mil poly.