Scissor trusses and baffles in vented roof assembly

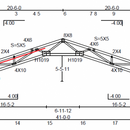

We’re building a new house (first one… and maybe last!). We have a 4/12 pitch vaulted ceiling created by parallel scissor chord trusses (see image below).

I’ve read over https://www.greenbuildingadvisor.com/article/site-built-ventilation-baffles-for-roofs and have done other research as well. I’m mostly wanting to confirm that it seems that the baffles should extend all the way up to the flat part (red). Yesterday I met with an insulation contractor and he just wanted to extend the baffles “enough” (green). The current plan is to do blown-in dense packed cellulose in the walls and ceiling.

Question: How far up should the baffles extend? Red or green… or something different?

Additional Details…

* Climate Zone 5/6 (Spokane, WA)

* Trusses span 41 ft.

* 4/12 pitch of roof

* Pretty tall energy heels

* All options are on the table as far as loose fill, dense pack, etc.

* Using AeroBarrier for air sealing is an option, but it will depend on cost. Not sure if that is relevant here, but I thought I’d mention it.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Provide a clear 2" gap for air to flow soffit to ridge. Some (??) advantage to blocking wind washing with baffles. As with walls, you want good vapor permeability to the exterior - so if you use baffles, consider the material.

Hi user-7498767 (it would be nice to get your real name).

To be specific, what you are showing is a parallel chord truss, not a scissor truss. They are different and have different implications for insulating. If you plan to dense pack the ceiling, you will be filling the entire roof area, and your baffles will have to extend all the way from the eave intake to the ridge.

Talk to your insulation contractor about the type of baffles they plan to use as the dense pack install could collapse lower quality baffles and compromise the ventilation channel.

Also, you may want to ask the contractor how they will ensure density across such a big space (the open trusses don't create separate cavities). I have heard of this being a problem in double-stud walls and some builders block off the walls into sections to make it easier to get a better dense pack install.

@Brian Pontolilo: Sorry. Didn't see that my name wasn't on there. Also, I may have misunderstood the insulation guy yesterday. Maybe he was wanting to do loose fill up there, but dense pack for the walls. If it is meant to be loose fill in the trusses, would you go with the green line, red line, or something else?

Hi John.

Like those below have said, you're probably still going to need to carry the baffles up beyond the insulation in the flat part of the ceiling. I would think that even loose fill will mostly fill the space. Even if it didn't, extending the baffles beyond the height of the insulation will keep the ventilation chanel open if you do have settling, which is a risk in a roof like this, albeit a small risk.

User ...767,

If the roof is indeed going to be dense-packed, rather than simply filled with cellulose like most truss spaces, then neither the red or green shown are adequate. The baffles need to extend over any area where the insulation will touch the roof sheathing - that is they need to be continuous from eaves to ridge. If loose-fill is used then the baffle could end as shown in red as long as a gap is left at the peak. In neither situation would the baffle shown in green work as it doesn't provide a continuous ventilation gap.

The baffles need to go to the ridge otherwise they'll get blocked by insulation.

Your roof slope also looks low enough for blown in insulation, there should be no need to dense pack. This would simplify the install, you don't have to worry about bowed ceilings and should be cheaper since it is quicker and uses less material.

You can search the site, there is a writeup somewhere about the slope limits for blown insulation.

Akos,

I agree - and if the whole cavity were filled, any incidental settling would just leave a small gap at the peak.

@Akos: Insulation guy said that 4/12 (which is what we have) is the steepest you can go for the method he advocated for. I've also updated the question with that info. Thanks.

That is quite a span ! I would create a dedicated airspace below the roof decking from eave to ridge with fiberboard or OSB. Typical blown insulation as suggested should be fine. Pay attention to the warm side air barrier.

Doug,

I wonder at what p0int it becomes easier to cover the trusses with house-wrap, and strap the top chords with 2"x2"s before sheathing?

Malcolm,

Interesting concept, have you used it? My concern would be the integrity (depth) of the airspace as in overblown, loose fill insulation. Could be tough to build as well especially here in the great white north. We usually brace our truss rafters with 2x4 (nailed to the top chord) before sheathing. I guess I would rather work from the inside, somewhat out of the weather. My suggestion goes quite well with 1x2, a 1/2 crown stapler and table saw. I like to air seal the edges of the continuous rigid air space material. The insulation will perform much like a wall enclosed on all sides.

The idea came for a 475 video, but I can't find it now. I had the same misgivings about actually doing the work you have.

Yes it is!!

So, do you mean that every "bay" would get a 2nd layer of OSB baffle held down 1-2 in. from the roof deck? How would the long sheets of OSB be installed? Toenailing into the truss members?

John,

The 1x2" spacer strips are installed right below the roof deck and are stapled crosswise into the roof truss top chord. I like to use 1/2" crown by 1 3/4" staples for this. If you want more than a 1 1/2" airspace use wider spacers. The plywood, fiberboard or OSB baffles are then stapled to the bottom of the spacers. The rigid chutes can be a full 8' length.

If you are blowing full the space between the interior sheathing and the rigid baffles I think you can go beyond a 4/12 pitch for blown insulation. I used this method on a 5/12 (R-65 ceiling) without concern. The air barrier and drywall are installed in advance up to a point near the ridge. Leave about 2' or so open so the insulation installers can blow the space full. They will net the top portion, complete the blow and then you can finish the air barrier and drywall.

Thanks for the replies so far!

I've updated the question with some additional details. If you've replied already, please let me know if that changes anything on your previous reply.