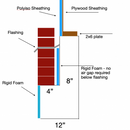

Sheathing over Wall detail (Brick Shelf & Exterior Insulation)

Hi GBA Community,

I’m trying to work in some exterior insulation sheathing for my new home that I am building (Northeast Zone 5). My architect didn’t spec any so it seems like I am on my own. My framers are asking me to decide how thick I want to go with it. I had planned on using the Polyiso from Johns Manville because this would get me the most R-Value by the inch. With 2″x6″ exterior walls with planned Rockwool or Cellulose, I cannot get anything greater than what the code requires for R-Value, hence my plan to bring in some exterior insulation.

My question is around where the sheathing meets the foundation. I have a 12″ foundation wall with a 4″ brick shelf. I understand that you want the 2″x6″ sill plate to line up with the outside of the wall allowing the plywood sheathing to overlap the foundation wall. Unfortunately with my brickshelf, I’m already limited with space and I need to maintain the recommend 1″ air gap. Question is, from what I know you normally want the plywood sheathing to overlap the foundation wall. In my case, can the plates be moved in where the plywood and insulated sheathing be flush with the wall instead? Then I’d have to cantilever the brick at least another 5/8″ to get that 1″ gap. How big of a deal is this gap anyway?

Any other suggestions/approaches would be helpful. I may be going about this all wrong. I’m in this position because the foundation contractor only formed a 4″ brick shelf, should have increased that another 1″ to give me some more breathing room. I through together an example of what I was seeing in my head, but any advice would be huge.

Thanks,

Jason

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Jason,

Isn't this the same question you asked a couple of weeks ago?

Hi Malcom!

We had an exchange sort of related to this back in December, but never had a chance to connect with you after my last reply. This post is more focused on where the plywood/sheathing meet the foundation wall. Is it that necessary to overlap? If not, then I can really add as much insulation as possible as long as the plate sits on the wall. Would you recommend anything to seal that joint? Is it necessary?

Also, as I try to learn more about the brick masonry. How important is the 1" gap? Is 3/4" good enough? I plan on moving the through wall flashing up so I don't have to worry about the concrete any more, its more of the framed walls at that stage.

Jason,

- You don't need to overhang the sheathing. In fact keeping it or the insulation flush makes taping the intersection between it and the concrete below easier.

- The 1" gap is pretty important. I wouldn't reduce it.

- The fundamental problem with your detail is that the exterior insulation isn't continuous so that heat loss bypasses it at the brick ledge and through-wall flashing.

Thanks Malcom - I understand now, I altered the detail to account for that. I moved the flashing up and extended the rigid foam up.

I think I should be ready to go now.

Last two questions. First on cantilevering the brick, 5/8" of an inch should be fine right? It seems to be within the limit/suggestion of no more than 1/3 of the overall brick thickness mentioned here (https://www.gobrick.com/docs/default-source/read-research-documents/brick-briefs/supporting-brick-masonry.pdf?sfvrsn=0)

(assuming the brick I use is 3 5/8" thick)

Any suggestions on the best through wall flashing for this type of application? I was thinking of going with Grace's Perm-A-Barrier® Wall Flashing.

This has been great thanks!

Jason,

Yes 5/8" is fine for a cantilever.

Unfortunately you still have a significant thermal bridge in your exterior insulation where the brick sits on the foundation. Seeing as you are probably planning to use rigid insulation on the interior of your basement or crawlspace walls, why not transition the foam at the top of the foundation from the exterior to the interior? That also avoids having to provide protection for it where it is exposed above grade, and keeps it safe from pests.

I'm sorry I don't know what best to use for the thr0ugh-wall flashing. I haven't done a brick clad building for more than thirty years since I moved west.

Thanks Malcolm - Your advice is greatly appreciated. Where I was getting confused was based on a Penn State presentation I came across online. Your point makes sense. The presentation on the other hand is sort of confusing. The 1st slide explains what you are talking about, the 2nd slide says the complete opposite and the 3rd goes back to what you were talking about. I guess If I can pull off a detail like in the left hand bottom corner of the 1st slide I'll be in business.

Jason,

That is confusing!

I can't imagine setting any masonry on rigid foam, no matter how high the compressive strength. Transitioning to the interior at the top of the foundation is by far the easiest and most effective option.

Hi Malcom, I know you mentioned at one point moving in the walls. After talking to my framer he suggested the following option in order to gain some additional space for exterior insulation. Instead of moving the sills we would keep the sills in the space according to the plan and the way the anchor bolts were laid out by the foundation contractor (middle third of plate). Then what we could do is start the sheathing a 2" in to allow for the exterior insulation to be worked into the assembly. In summary, we wouldn't add exterior insulation to the sills. Any thoughts on this?

Jason,

Sure that would work fine. especially if you are moving the rigid insulation on the foundation to the inside, and it could be brought right up to the underside of the floor trusses. Just make sure you have enough bearing on the sill-plate left for the trusses and any rim-joist they may require. Also ensure the WRB laps over the sill-plate.

Thanks Malcom! - I will bring up the rigid on the inside wall to address that gap we have be talking about . I'll review this with them today, I do believe they were saying that there will still be enough meat left over for the trusses + rim joists.

Jason,

Good luck with your build!