Thermal bridging with a masonry pier foundation

Hi folks,

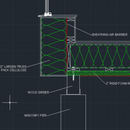

I am brainstorming how to eliminate thermal bridging with a pier foundation which I could not find much information on. As you can see in the picture there is rigid foam placed between the wood girder and the wooden foundation. The rigid foam could easily handle the load.

As you can see there still is a thermal bridge being the bolt connecting the foundation to the pier but I would think this would be better (but perhaps I am wrong). Anyone have and thoughts or information on this matter?

Thank you.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Oliver, Accepting that the rigid insulation has been engineered to take the uniform and point loads imposed by the structure, what is the purpose of the 2x strapping? It seems like a lot of the work has to be done from the underside: Some sort of webbing to keep the cellulose out of the cavity, the strapping, the rigid insulation and the sheathing. Anything that you can eliminate is going to save a lot of awkward work. I'm sure the I-joists can be fastened through the foam with structural screws. They, or the lag screws you show, will have a negligible effect as thermal bridges.

Malcolm, thank you for the feedback. Glad to hear that the lag screws would not be of significance as far as thermal bridging. I do question whether a 2x6 under the 2x12 floor would distribute the load evenly enough, obviously something I would need to talk to a structural engineer about. As far as the strapping, my thought was so that the foam insulation was continuous, certainly would not have to be 2x4's. I did some adjusting and perhaps these examples would be better. The first one simply takes out the strapping and moves the sheathing/air barrier directly against the 2x12's but the negative is that the foam is no longer continuous (not sure how big of a deal this is). The second would be notching the 2x12 joists so that the 2x6 was recessed and the air barrier and foam insulation was continuous. Notching the joists before installation would definitely be easier than the awkward installation of strapping.

I'm not sure how confident I would be resting an entire house on some small pieces of foam, even high-density 50+ PSI foam, especially considering how foam can be eaten over time by insects. I'd go for a stronger masonry-based insulation here. Maybe Foamglas blocks, AAC blocks, or even refractory bricks. Europeans have all kinds of interesting masonry-based insulating materials that sadly aren't available in the USA that would be perfect here.

Oliver,

1. I think you are overthinking this. If I were you, I wouldn't worry about the small amount of thermal bridging directly over the piers. I would just install a continuous horizontal layer of rigid foam on the underside of the joists -- the foam would cover 95% of the joist area, just not the 5% of your floor immediately above each pier.

2. If you want to go ahead with your plan, be sure to talk with an engineer.

3. If you can't sleep at light because of the thermal bridging, you could always address the thermal bridging from above, using a foam sandwich at the subfloor (OSB / rigid foam / OSB or plywood / rigid foam / plywood) -- a type of site-built SIP.

Some insulation material options include:

Atlas "X-grade" EPS that include a termiticide and is available in up to 60 psi type XV (3 lb/cubic foot)

Compacfoam super high density structural foam which starts at 6 lbs per cubic foot/200 psi and is also availabe in 12 lbs/cubic foot from 475, and is made in even higher densities.

https://foursevenfive.com/product-category/thermal-insulation/compacfoam/

I'm wondering about the main area under the floor, where I think you have deep cellulose with foam under it. That's like a wall with foam on the outside, and you need to be sure the ratio of thicknesses is OK for your climate zone. I'm not sure what your climate zone is, but some possible solutions are to omit the foam over most of the floor area, or to use mineral wool. Martin's suggestion of moving the foam layer to the inside would also help in cold climate zones.

Charlie, The climate zone is 7a. I overlooked the fact that it would be better to have the foam on the interior, thank you for pointing that out. Martin, thank you for the idea of the foam sandwich, I will investigate going that route and also need to look at some of your articles regarding interior vs exterior foam in a 7a climate. I probably am overthinking this, it is good to hear that from some experts because I do share some of the reservations about the entire load of the house resting on so little foam although the numbers do look favorable. Say there were 3 girders that are 30' long supporting the 1 story house. Assuming that 2 of the girders would share the majority of the load, With 25 psi foam it would not yield until 5.5"x(60'x12")x25=99,000 lbs. I guess the big question here is how evenly distributed the load is.

At any rate, I think I might need to get a better understanding of how to calculate thermal bridges before going any further. I think I have a pretty good handle on PHPP software except for the thermal bridging. Given that I am not actually trying to design a passive house but more along of lines of a pretty good house, should I not be so concerned with thermal bridging?