Type I or Type VIII EPS under a concrete slab

I will be building soon in Climate Zone 5 and I am planning to insulate under the concrete basement slab with 2″ of EPS foam. I found an inexpensive local source of Type VIII EPS (which has 13 psi compressive resistance) that I would like to utilize but I am uncertain if this foam type is adequate.

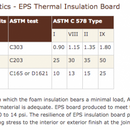

Multiple articles on GBA recommend that under-slab insulation be Type II EPS (15 psi compressive resistance). However, I found the attached information on the EPS Industry Alliance web site (epsindustry.org) which states that Type I EPS (and presumably Type VIII as well since it has higher compressive resistance compared to Type I) is adequate under slabs.

Given a bearing load of 50 psf for the 4″ thick concrete and adding a conservative 100 psf for a combination of additional dead loads and any live loads results in only 1.04 psi of compression acting on the foam. Seems that even Type I EPS provides a safety factor near 10.

What is the general wisdom here at GBA: Can Type I and Type VIII EPS be used under concrete slabs? If not, why not?

Thanks,

Jim

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Jim, there is little functional difference between 13psi and 15psi, so I think type VIII would be fine. Type 1 would probably be ok as well but it's very soft and crumbly to work with so I would go for the higher strength version. In any case, none of these types is appropriate under a structural load, but I assume you already understand that.

My whole house is resting on 12" of EPS type I. I'm pretty sure, I really hope, that's what the engineer signed off on.

I just checked, and the minimum strength requirement was 25kPa, which is about 3.6psi. Now, this is for a floating slab. If you're talking about foam under footings, that's obviously a different kettle of fish since there's much less surface area supporting the same loads.

Trevor, you should be fine. For a 4" slab the dead load is about 50 lbs./sq. ft.. Call the live load 40 lbs, for 90 lbs. total load. Force travels down through concrete at an angle, so that 90 lbs is really spread out over about 2.5 sq. ft. when it reaches the foam, but to be conservative let's say the foam is actually supporting 90 lbs./sq. ft., or 0.625 lbs./sq. in.. That's less than 1/10 of your type 1's load rating of 10 lbs./sq. in.. The load rating is based on 10% deflection, and engineers derate it another 30% to account for long-term creep, but you still have plenty of leeway. That said, walking on type 1 foam, especially relatively thin layers, is prone to break the foam, and the edges crumble readily. I spec Type II EPS under slabs and it's almost as nice as XPS to work with. Type II also has almost 10% higher R-value per inch than Type 1.

We were working with 4" and 12" thick sections. I can definitely confirm the edges are prone to sloughing. If I had to do it again, I would specify the perimeter pieces be type II.

I have type I under my house, which is a two story house on 8" of concrete. Even 10psi foam works out to 1440lbs per square foot, or ~2.2 million pounds load limit for a 1500 square foot house.

The biggest issue with Type-I under the slab is drainage due to the large fraction of open cells and larger interstitial spaces between beads, but as long as there is the requisite amount of washed gravel under the foam it'll be fine.

The other issue with Type-I in thinner sheets or layers is that it's not "walkable" without leaving boot-print impressions, or breaking the boards. With Trevor's 12" of EPS a few boot dents isn't a problem, but if it's only 2" you'll probably break or permanently dent a few of the boards deep enough to matter.

Type VIII is a bit more rugged to that type of abuse- it's used under membrane roofs that occasionally get walked on, and it's not necessary to coddle it in a sub-slab application.

Something that has always worried me is watching type one EPS take on water in hot tub lids. Once they are waterlogged you can put them in a heated room and they take weeks to lose the locked in moisture. I wonder if a similar thing happens with sub-slab foam, and what that does for the insulating value?

Thanks for all the replies. Looks like the Type VIII that I can source locally will do the job. And it is far less expensive than the XPS my builder was planning to use. Win-win!