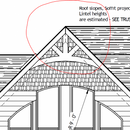

Vaulted ceiling steel ridge beam edge insulation

Hi everyone, we are building a great room with vaulted ceiling in it. The roof will be supported by a steel ridge beam resting on steel posts at ends.

Exterior sheeting will have R5 insulation and we will have vapour barrier on the interior side.

Our walls will be R27 overall and ceiling will be R60.

Do you think having R5 on the edge of the steel ridge beam is enough to stop thermal break and prevent condensation on the ridge beam or should we have more insulation added between exterior sheeting and the edge of the beam?

I’ve attached the detail drawing and elevation indicating detail location.

EDIT: we are in Toronto, Canada area. The walls usually have between R20 and R27 insulation requirements. Vaulted ceiling has R31 requirement min.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Hi Maria -

1. More important than the vapor barrier is making sure the wall and roof air barrier meet and ensure that warm moist air does not "see" the beam.

2. Conductive heat flow is agnostic when it comes to direction: having R60 on top of the beam and R5 on the side is not proportional.

IF there is no air leakage, that R5 can still create quite a thermal bridge with the beam, and though with an air control layer you may not get condensation on the beam, it will in turn make materials around it colder, and THEY may reach dewpoint.

Get as much R-value as you possibly can on the butt end of the beam.

And yes, of course climate makes a big difference (not sure where you and your building are--always good to include that).

Peter

Thank you, Peter. We are in Toronto area in Canada if this changes any of your recommendations.

What climate zone are you in? I’d try to have at least the minimum thickness of exterior foam recommended for your climate zone between the end of the beam and the exterior of the house. The minimum foam thicknesses are intended to minimize condensation forming inside the wall which is the same thing you want with your steel beam.

Steel is going to conduct heat much more than wood would, but the end of the I beam is also quite small in cross sectional area compared to what a big glulam or similar wood beam would be, which somewhat reduces the relative energy losses of the steel compared to wood framing. I’d try to insulate the sides of the web and flanges a bit where it’s inside the wall to somewhat encapsulate the very end of the beam.

Bill

Thank You, Bill. We are in Toronto area in Canada.

Our wall is required to have continuous R5 on the exterior and R22 between the studs, but there is enough houses with R20 in the walls.

Maria,

Looking at your hand sketch it looks like your ridge beam is bellow the insulation and inside the thermal envelope, thus it will be hot. Steel is a good conductor of heat. The edges, specially with R5 insulation will never get cold enough to cause issues.

Condensation would start only if that steel ridge beam continued outside the house to support a large overhang. The key with any steel is that you never want it to be running through your thermal envelope.