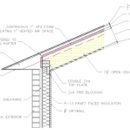

Vented open-cell cathedral ceiling

Good afternoon – What are the draw backs to venting an open cell spray foam cathedral roof assembly?

To note – the original roof assembly was design was with R30c kraft face batt insulation. – The framing inspector is concerned that I have a double vapor barrier between the kraft face and rigid XPS.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Bob,

Q. "What are the drawbacks to venting an open-cell spray foam cathedral roof assembly?"

A. None, as far as I know. There are benefits.

Q. "The framing inspector is concerned that I have a double vapor barrier between the kraft face and rigid XPS."

A. The kraft-faced fiberglass is on your wall, not your ceiling. I'm confused by your inspector's concern. Are you talking about the wall assembly or the ceiling assembly?

Neither 1" XPS nor a kraft facer on a batt is a vapor barrier. A vapor barrier is defined in code as a "Class-I vapor retarder", which is a vapor permeance of less than 0.1 perms.

At 1" most XPS isn't even a Class-II vapor retarder- it's over 1 perm (but not by much- typically ~1.5 perms @ 1", give or take a few tenths). That's still more than 10x the vapor permeance of a vapor barrier.

Asphalted kraft facers are under 1 perm when the entrained air in the insulation is dry, but rises to 5+ perms (which is more vapor open than standard latex ceiling paint) when it's humid enough to support rapid mold growth.

I noticed in the detail drawing that you're sistering-on 2x10s to a 2x4 top chord truss. The thermal bridging of that 2x10 undercuts the performance of the insulation.

It would be higher performance to add a 2x4 spaced at the distance of the intended insulation depth, which would provide a significant thermal break on the framing as opposed to a thermal bridge.

Martin - The original design was to use kraft face R30c batt insulation (see attached) against the site made XPS baffle. When the framing inspector came out he voiced his concern about trapping moisture between the kraft face and the XPS baffle. As Dana has pointed out, it sounds as though the XPS @ 1" will allow drying towards the exterior of the house.

Dana - is the kraft face similar to a smart vapor barrier? -> Going from 1 perm when dry to 5 perm when moist sounds like it helps moisture escape?

Also, Dana I am not sure I follow where you are adding a 2x4 -> would this be parallel with the sistered 2x10?

Final question of the two roof assemblies - Which would be the better roof? Using the Batt approach or spending more $$ on a vented open cell assembly?

Thanks for the quick responses!!

Bob,

Your building inspector's concern is baseless. As Dana explained, vapor can pass through 1 inch of XPS. There is also some vapor transfer (drying to the exterior) through the sides of the rafters (which have contact with the air moving through the ventilation gap). For more information on this issue, see Site-Built Ventilation Baffles for Roofs.

Kraft facing is, indeed, a smart retarder with variable vapor permeance.

Open-cell spray foam and fiberglass batts have about the same R-value per inch. If perfectly installed, the fiberglass batts will perform as well as the open-cell spray foam. That said, batts are rarely installed perfectly, so the spray foam would usually perform a little better. It's expensive, though.

>I am not sure I follow where you are adding a 2x4 -> would this be parallel with the sistered 2x10?

No, the 2x4 would be INSTEAD of a sistered 2 x 10, with the bottom edge of the 2x4 placed where the bottom edge of the 2x10 might have been.

By sistering on a 2x10 you're doubling the framing fraction for the exterior 3.5" (the 2x4 truss chord/rafter), but then extending that low-R wood through the insulation layer. If a 2x4 was used instead there would be at least R8 of open cell foam between the bottom edge of the original 2x4 truss element and the top side of the new 2x4. With a sistered 2x10 that space would be filled with R2.5-ish wood.

So between the R8 thermal break of replacing some of the 2x10 wood with foam and the smaller framing fraction on the exterior side, the overall thermal performance improves pretty significantly.